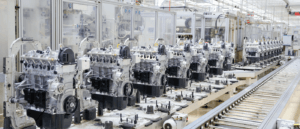

When it comes to powering industrial operations, inverters[^1] are the backbone of efficiency and reliability. Whether you’re running heavy machinery, managing renewable energy setups, or ensuring seamless operations during power outages, the right inverter can make all the difference! In this guide, we’ve curated the top 10 inverter brands for industrial applications in 2024[^2], highlighting their standout features, innovations, and why they’re trusted by industries worldwide.

Industrial inverters[^3] ensure efficient energy use, minimize downtime, and provide reliable power. Selecting the right one is essential for success.

Keep reading to explore top brands, key features, and additional insights into future trends, FAQs, and procurement tips to make the best decision for your business.

What makes an Industrial Inverter Suitable for Your Applications?

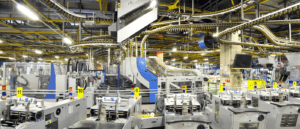

Inverters for industrial applications[^4] are engineered to handle high-capacity loads and challenging environments

Key industrial inverters[^5] offer durability, energy efficiency, and advanced control systems[^6], setting them apart from residential models.

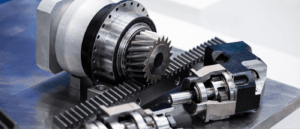

Differences Between Industrial and Residential Inverters

| Feature | Industrial Inverters | Residential Inverters |

|---|---|---|

| Power Capacity | High, supports heavy machinery | Lower, supports household appliances |

| Scalability | Modular and expandable | Limited scalability |

| Durability | Built for harsh conditions | Standard durability |

| Advanced Features | Smart control, remote monitoring | Basic functionality |

Industrial inverters must deliver continuous performance under high stress. This sets the stage for the top brands excelling in 2024.

Top 10 Industrial Inverter Brands Applications in 2024

Our selection criteria included innovation, reliability, market reputation, and customer reviews. Below are the leaders:

1. Schneider Electric

Schneider Electric is synonymous with energy management and automation. Its inverters excel in scalability and advanced system integration.

Schneider's EcoStruxure platform offers robust solutions for large-scale power management needs.

2. ABB (ASEA Brown Boveri)

ABB leads in industrial automation and power electronics. Their inverters are known for efficiency and smart connectivity.

ABB’s solutions combine power and precision, ideal for modern industrial needs.

3. Siemens

Siemens offers a range of large-scale inverters catering to manufacturing and energy sectors.

Flagship models like SINAMICS G120 emphasize performance and reliability in complex applications.

4. Delta Electronics

Delta Electronics is trusted for its energy-saving and innovative designs.

Delta's industrial inverters excel in renewable energy and high-efficiency applications.

5. Mitsubishi Electric

Known for precision engineering, Mitsubishi Electric offers inverters designed for optimal power use.

Their systems are highly reliable and widely used in automation and robotics.

6. Hitachi

Hitachi delivers eco-friendly and high-performance inverter solutions for heavy industries.

Their inverters are known for seamless integration and reliability in critical applications.

7. SMA Solar Technology

SMA specializes in solar-powered and hybrid industrial applications.

Their solutions are ideal for industries transitioning to renewable energy sources.

8. Yaskawa Electric

Yaskawa excels in motion control and manufacturing automation.

Their inverters deliver high reliability and are trusted by automation-intensive industries.

9. Fuji Electric

Fuji Electric focuses on power electronics for critical infrastructure.

Their industrial inverters are designed for heavy industries and power-intensive environments.

10. General Electric (GE)

GE is renowned for scalable, robust inverter solutions.

Their product range covers a wide array of industrial needs with unmatched reliability.

Future Trends in Industrial Inverters

Industrial inverters are evolving rapidly, driven by advancements in technology and the increasing demand for efficiency and sustainability. Here’s a deeper look at what to expect in the future:

1. AI-Powered Diagnostics[^7]

Artificial intelligence is transforming the way industrial inverters operate and maintain performance. Inverters equipped with AI algorithms can:

- Predict and diagnose faults before they occur, reducing downtime and repair costs.

- Analyze energy usage patterns to optimize performance and minimize waste.

- Enable self-healing capabilities by automatically adjusting to avoid system failures.

These advancements improve reliability and make AI-powered inverters a critical tool for industries prioritizing uninterrupted operations.

2. Hybrid Energy Systems[^8]

The integration of multiple energy sources is becoming a standard feature in industrial inverter design. Hybrid systems combine:

- Renewable energy sources like solar and wind with traditional grid power.

- Battery storage solutions to ensure uninterrupted energy supply during fluctuations or outages.

- Dynamic load management to prioritize the most cost-effective and sustainable energy source at any given time.

This versatility makes hybrid systems ideal for industries striving to reduce their carbon footprint and operational costs.

3. Advanced IoT Integration[^9]

The Internet of Things (IoT) is revolutionizing industrial energy management. IoT-enabled inverters[^10] provide:

- Real-time monitoring of energy flow and equipment health.

- Remote control capabilities, allowing adjustments and troubleshooting from anywhere in the world.

- Enhanced data analytics for predictive maintenance and energy optimization.

By leveraging IoT, industries can achieve higher levels of automation and efficiency, reducing manual intervention and improving overall productivity.

4. Enhanced Energy Storage Integration[^11]

The future of industrial inverters is tightly linked to advancements in energy storage. Modern inverters are:

- Designed to seamlessly integrate with high-capacity battery systems.

- Equipped with bidirectional capabilities, enabling energy storage during low demand and supply during peak usage.

- Capable of supporting emerging technologies like solid-state batteries and flow batteries, further enhancing efficiency and storage life.

These features ensure that industrial setups can store excess energy for use during outages or peak demand, improving sustainability and resilience.

5. Focus on Sustainability and Decarbonization[^12]

As industries shift towards more sustainable practices, industrial inverters are evolving to meet environmental goals. Trends include:

- Inverters certified for high energy efficiency standards, reducing overall consumption.

- Support for green energy projects, including microgrids and off-grid renewable energy setups.

- Compliance with global sustainability goals, making them attractive for environmentally conscious businesses.

6. Modular and Scalable Designs

The future of industrial inverters lies in flexibility. Modular designs allow industries to:

- Scale up or down based on energy requirements without replacing the entire system.

- Simplify maintenance by enabling repairs or upgrades to individual modules.

- Reduce upfront costs by allowing gradual expansion as needs grow.

Why It Matters

Investing in brands that innovate in these areas ensures:

- Long-term competitiveness by staying ahead of technological trends.

- Significant cost savings through improved efficiency and reduced downtime.

- Alignment with global sustainability and operational excellence goals.

Businesses adopting these forward-thinking inverter technologies will position themselves as leaders in their respective industries.

FAQs About Industrial Inverters

Q: How do I determine the right capacity for my business?

A: Calculate your total energy needs, including peak loads. Factor in a 10-20% capacity buffer to ensure scalability and accommodate future energy demands. Learn more about calculating inverter capacity%20%3D%201%2C800%20watts.)[^13].

Q: What maintenance do industrial inverters require?

A: Routine maintenance includes:

- Regular cleaning[^14] to prevent dust accumulation.

- Performing software updates for optimal functionality.

- Inspecting components for wear and tear, such as cables, cooling systems, and internal circuitry.

- Monitoring performance logs for early detection of anomalies.

Q: Can I retrofit a new inverter into an older system?

A: Yes, retrofitting is possible, but it requires:

- Ensuring the new inverter is compatible[^15] with your existing system.

- Checking voltage, current, and communication protocols.

- Collaborating with professionals to reconfigure or upgrade system components if necessary.

Q: How do industrial inverters differ from residential ones?

A: Industrial inverters[^16] are designed for higher capacities, scalability, and rugged environments, whereas residential inverters are built for smaller, less demanding applications. Industrial models often include advanced features like IoT connectivity and AI diagnostics.

Q: Are warranties important when purchasing an inverter?

A: Absolutely. Longer warranties often indicate higher product quality and offer peace of mind for long-term reliability. Always compare warranty terms[^17] across brands and include service agreements when available.

Q: How do industrial inverters differ from residential ones?

A: Industrial inverters[^18] are designed for higher capacities, scalability, and rugged environments, whereas residential inverters are built for smaller, less demanding applications. Industrial models often include advanced features like IoT connectivity and AI diagnostics.

Q: Are warranties important when purchasing an inverter?

A: Absolutely. Longer warranties often indicate higher product quality and offer peace of mind for long-term reliability. Always compare warranty terms[^19] across brands and include service agreements when available.

Q: How can I reduce energy costs with an industrial inverter?

A: Choose an energy-efficient inverter[^20] with features like peak load management and renewable energy compatibility. Regular maintenance and using the inverter at optimal capacity also minimize energy waste.

Best Practices for Negotiation and Procurement

- Compare Quotes:

Gather detailed quotes from multiple suppliers. Look beyond price; evaluate features, warranty terms, and after-sales support to determine the best overall value - Negotiate Warranties:

Insist on extended warranties, which often indicate the manufacturer's confidence in their product. A longer warranty reduces the risk of unexpected repair costs over the inverter's lifespan. - Consider Service Agreements:

Opt for packages that include regular maintenance, remote monitoring, and technical support. These agreements ensure your system operates smoothly and minimizes downtime. - Research Supplier Reputation:

Choose suppliers with a proven track record in the industry. Verified distributors and established brands reduce the risk of purchasing counterfeit or subpar products. Check customer reviews and request references if needed. - Evaluate Delivery and Installation Support:

Some suppliers offer complete installation services or partner with certified technicians. Ensure your chosen supplier provides timely delivery and installation expertise to avoid delays. - Leverage Bulk Purchases:

If your business requires multiple inverters, negotiate discounts for bulk orders. Suppliers are often willing to offer better pricing for larger purchases. - Request Product Demos:

Whenever possible, ask for a demo or trial of the inverter. This provides an opportunity to verify performance and compatibility with your specific needs.

By following these practices, you can ensure a successful procurement process, securing the best product for your business while maximizing long-term value.

Benefits of Using High-Quality Industrial Inverters

Investing in high-quality industrial inverters provides numerous advantages that directly impact operational efficiency and cost management:

- Reduced Downtime and Maintenance:

Reliable inverters minimize the risk of unexpected breakdowns, reducing costly production halts. High-quality systems often come with advanced diagnostics and self-maintenance features that proactively address issues before they escalate. - Improved Energy Efficiency:

High-grade inverters are designed to optimize energy usage, significantly lowering electricity consumption. This not only reduces operational costs but also contributes to sustainability goals by minimizing waste. - Scalability for Evolving Business Needs:

Quality inverters offer modular designs and robust capabilities that support scaling operations. Whether expanding production lines or incorporating renewable energy sources, these inverters adapt seamlessly to growing demands. - Enhanced System Reliability:

Built for industrial environments, these inverters deliver consistent performance under harsh conditions, ensuring uninterrupted power supply and system stability. - Environmental Benefits:

High-efficiency inverters produce less heat and waste energy, which reduces the environmental footprint of industrial operations. Many models also support integration with renewable energy sources for greener operations. - Long-Term Cost Savings:

While initial investments in high-quality inverters may be higher, their durability, efficiency, and lower maintenance needs result in significant cost savings over their lifespan.

By choosing top-tier industrial inverters, businesses can achieve better performance, improved sustainability, and a solid foundation for future growth.

Conclusion

Choosing the right inverter impacts your industrial operations' efficiency, reliability, and costs. The brands listed here offer the best solutions for 2024, tailored to various industries and applications. With added insights into trends, FAQs, and procurement strategies, you’re better equipped to make an informed decision. Need expert help? Contact us today!

[^1] Clicking this link will help readers understand the importance and specific functions of industrial inverters, ensuring they grasp their value in operations.

[^2] This resource will provide comprehensive and updated insights into the most trusted inverter brands for industrial use, guiding informed purchasing decisions.

[^3] This link will explain the essential factors for selecting the right industrial inverter, tailored to specific needs.

[^4] This link explains how industrial inverters differ from residential models, helping readers identify the right product for their needs.

[^5] Readers can explore the unique features that make industrial inverters suitable for demanding applications, ensuring optimal functionality.

[^6] This link highlights the role of advanced control systems in enhancing performance and efficiency in industrial settings.

[^7] This link explains how industrial inverters differ from residential models, helping readers identify the right product for their needs.

[^8] Readers can explore the unique features that make industrial inverters suitable for demanding applications, ensuring optimal functionality.

[^9] This link explains how artificial intelligence is revolutionizing industrial inverters, enhancing predictive maintenance and performance.

[^10] Readers can explore how integrating renewable energy sources with traditional grids offers efficiency and sustainability benefits.

[^11] This resource outlines key advancements shaping the future of industrial inverter technology.

[^12] This link explains how bidirectional capabilities in inverters enhance energy storage flexibility and efficiency.

[^13] This link guides businesses on accurately determining energy needs for selecting the appropriate inverter capacity.

[^14] Readers can explore best practices for maintaining industrial inverters, ensuring longevity and reliability.

[^15] Learn the steps and considerations for integrating new inverters into older systems.

[^16] Understand the distinctions to ensure the right inverter type is chosen for specific applications.

[^17] Discover why warranties matter when evaluating inverter options for durability and support.

[^18] This link explains the key differences to help businesses choose the right inverter for their needs.

[^19] Learn why warranties and service agreements are crucial for ensuring long-term reliability and support.

[^20] Discover how to maximize efficiency and minimize costs with advanced inverter features and proper maintenance.