The world of factory automation is rapidly advancing, driven by technological breakthroughs and an urgent need for more efficient and intelligent manufacturing processes. Staying informed about the future of factory automation is essential for companies striving to remain competitive. Here are 10 critical facts that paint a vivid picture of what’s ahead.

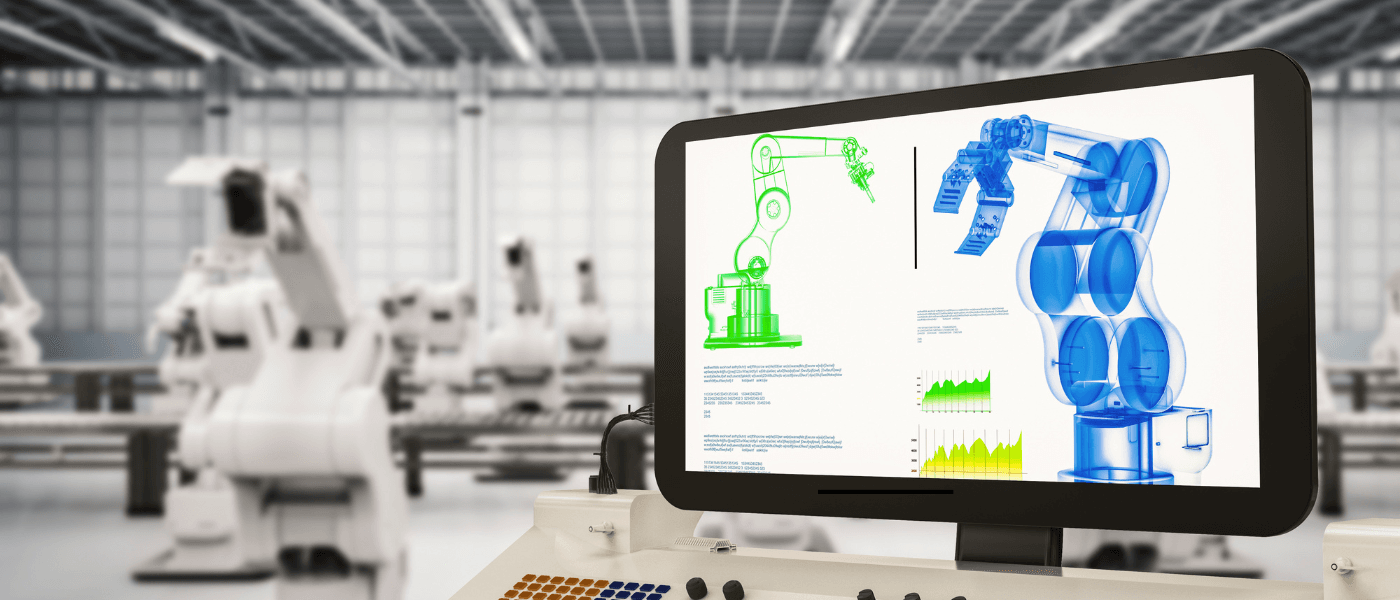

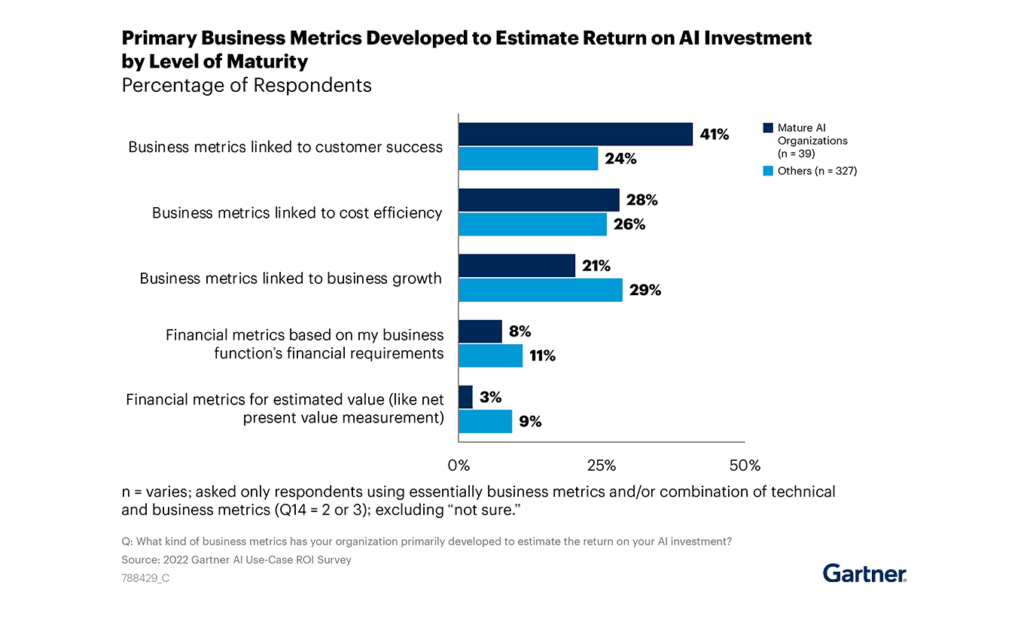

Artificial Intelligence Drives Optimization

Artificial intelligence (AI) is poised to transform factory automation by making processes more intelligent and efficient. AI's ability to analyze vast amounts of production data in real-time has already helped manufacturers identify inefficiencies, predict maintenance needs, and improve product quality. For instance, a global electronics manufacturer recently leveraged AI for quality control, resulting in a 40% reduction in defects (Gartner AI Report). With AI becoming ubiquitous, manufacturers can expect smoother operations and fewer production errors.

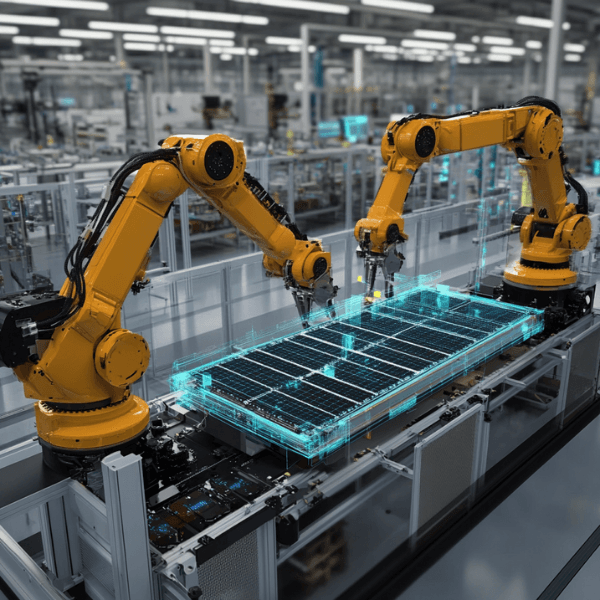

Robotics Market Is Set to Explode

The robotics sector, a cornerstone of factory automation, is projected to grow significantly. Industrial robots, including collaborative robots (cobots) that work side by side with human workers, are reshaping production lines. Companies in the automotive and electronics sectors have embraced cobots to boost efficiency and flexibility. Industry experts predict that collaborative robots will make up nearly 30% of the robotics market by 2028, highlighting their growing importance in flexible manufacturing environments. (marketsandmarkets)

Edge Computing Enhances Real-Time Processing

As the number of connected devices in factories multiplies, edge computing is revolutionizing how data is processed. Instead of sending data to remote servers, edge computing allows for local, near-instantaneous analysis, reducing latency and making factory automation more efficient. For example, an automotive supplier used edge computing to monitor assembly line performance, leading to real-time adjustments that minimized downtime and improved productivity. Experts forecast a 30% annual increase in edge computing adoption across the manufacturing sector. (Edge Computer News)

5G Connectivity Accelerates Automation

5G networks are set to revolutionize factory automation by providing ultra-fast, low-latency communication. This new level of connectivity is crucial for synchronizing machines and sensors in real time. A German car manufacturer has already deployed a 5G-enabled production system, which improved assembly speeds by 20% and allowed for seamless integration of robots and automated guided vehicles (AGVs). With 5G, factories can become smarter and more responsive to operational demands.

Digital Twins Optimize Factory Performance

Digital twins, virtual replicas of physical assets and processes, are becoming integral to factory automation. These digital models allow manufacturers to simulate production scenarios, test changes, and optimize operations without disrupting the actual workflow. A consumer goods manufacturer used digital twin technology to simulate production line configurations, which led to a 15% increase in throughput. The technology is expected to be a $48.2 billion market by 2026, demonstrating its crucial role in modern manufacturing. (Marketsandmarkets)

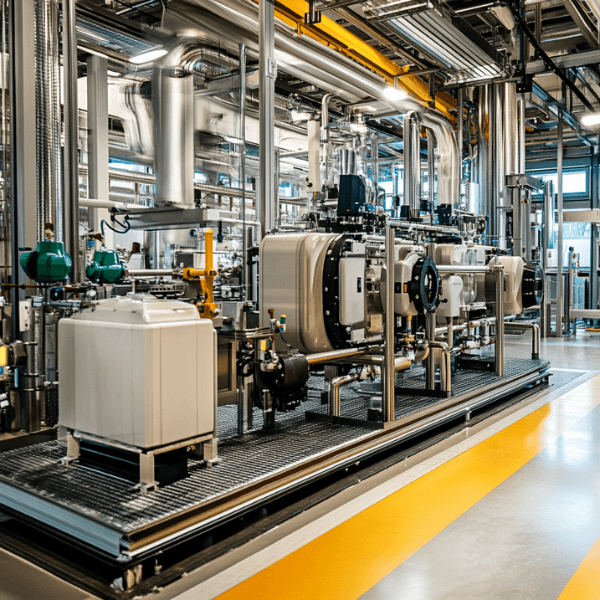

Sustainability Takes Center Stage

Sustainability is a driving force in the evolution of factory automation. Companies are under increasing pressure to reduce their carbon footprint and adopt energy-efficient practices. Factories are implementing automation solutions like energy-saving robots and automated energy management systems. A beverage producer, for example, implemented automated energy monitoring, cutting its energy use by 30% and meeting environmental regulations. As sustainability becomes a key focus, automated factories are set to lead the way in eco-friendly manufacturing.

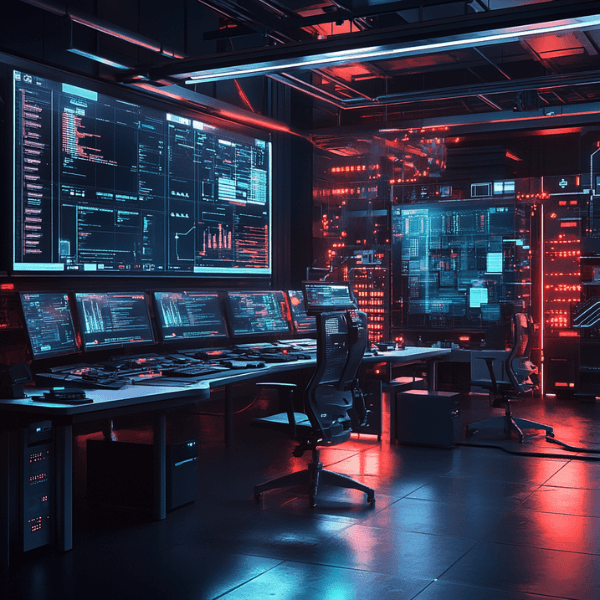

Cybersecurity Becomes a Critical Priority

With the rise of connected machines and networks, cybersecurity has become an essential part of factory automation. As cyber threats become more sophisticated, protecting automated systems from potential breaches is crucial. Industrial facilities are now investing heavily in cybersecurity, with global spending projected to hit $125 billion by 2025. Companies must implement robust security measures to safeguard their production data and ensure operational continuity in an increasingly digital world. (ivanti)

Reskilling the Workforce Is Essential

As factory automation advances, the roles of workers are changing. Instead of being replaced, employees are transitioning to roles that require operating and programming automated systems. For instance, a major industrial equipment manufacturer launched a reskilling initiative to train its workforce in robotics programming and data analytics, ensuring its staff stays relevant in the automated age. By 2030, 40% of manufacturing jobs are expected to require significant reskilling, making workforce training a top priority.

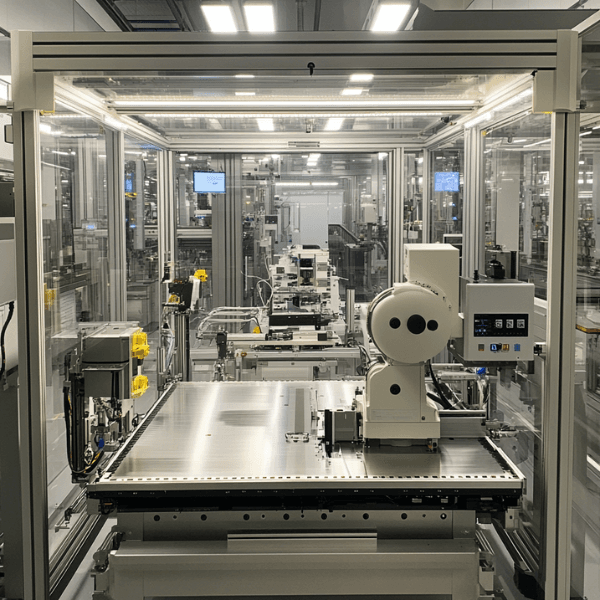

Smart Factories Are Becoming the Norm

Smart factories, which integrate AI, IoT, robotics, and data analytics, are rapidly becoming the new standard in factory automation. These highly connected facilities optimize every aspect of production, from supply chain management to quality assurance. A study by PwC found that 72% of manufacturers are planning to invest in smart factory initiatives. With this shift, companies can expect greater operational efficiency, reduced waste, and enhanced product quality.

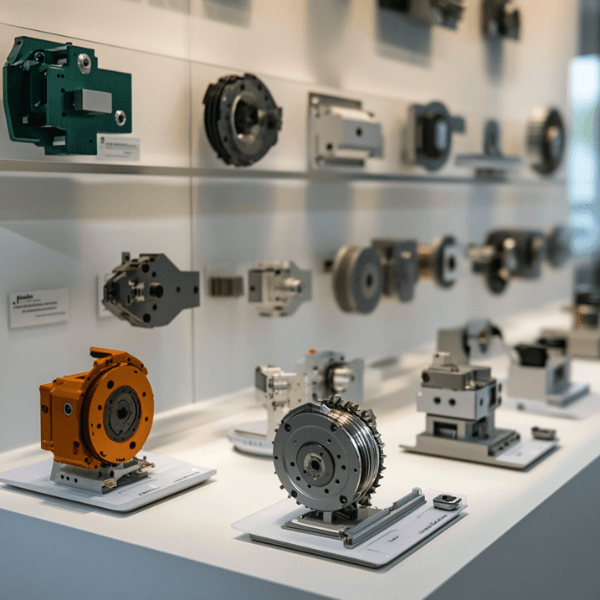

Uni Regal Corp. Ltd: Your Partner in Factory Automation

To successfully implement these innovations, manufacturers need reliable and high-quality automation components. Uni Regal Corp. Ltd. provides a comprehensive range of parts, including PLCs, HMIs, servo motors, and sensors from top brands like Siemens, Mitsubishi, and Allen-Bradley. Our expertise and extensive inventory make us the perfect partner for your factory automation journey. Whether you’re looking to upgrade your existing systems or invest in new technologies, Uni Regal has you covered.

Conclusion

The future of factory automation is dynamic and full of opportunities. From AI and robotics to edge computing and sustainability, understanding these trends is crucial for staying competitive. By partnering with Uni Regal Corp. Ltd., you can access the top-quality components needed to future-proof your operations and lead the way in automated manufacturing.