Problems in manufacturing? An outdated Human Machine Interface1 (HMI) can lead to inefficiency and errors. Don't let that happen to you!

The right HMI can greatly boost your plant's productivity, safety, and efficiency. In 2025, it's about selecting a system that aligns with your specific manufacturing needs, including features, integrations, and functionality.

Picking an HMI can feel hard. What is the best way to choose?

What is an HMI and Why Does It Matter in Manufacturing?

Ever wondered what connects your team to the machines? It's the Human Machine Interface, or HMI. Is it just a screen?

An HMI really is the visual interface that bridges the gap between operators and your machines. It allows your team to monitor operations, give commands, get system feedback, and see production data clearly.

Why it matters:

- Reduces downtime with immediate alerts and diagnostics.

- Increases operator productivity with intuitive interfaces.

- Enhances safety through automation and process visibility.

- Empowers better decision-making with real-time data.

Real-time data also leads to better decisions, and I think this might be HMIs' most understated benefit. With HMIs, you can visualize the data and have better handle on your operations. Let's not forget that HMIs are scalable to new needs, and that there are many types of HMIs available on the market. Choosing well can be hard, so make sure to check which HMI is appropriate for your needs.

Which Types of HMI Systems Are Available in 2025?

Not all HMIs are created equal. Do you know which type fits your plant's unique needs?

In 2025, you have choices like touchscreen, panel-mount, PC-based, web-based, cloud, and even mobile HMIs. What type that you should choose depends on your environment, your production needs, and how your workforce operates.

Touchscreen HMIs are common because they are quick and easy to use on the shop floor. I have been in plants where operators can learn to use them in minutes because of their intuitive design. They are great for fast interactions. Panel-Mount HMIs are built into control cabinets, which makes them secure and central to operations. You can use these in specific locations near machinery.

PC-Based HMIs are better for complicated processes that involve a lot of data visualization, which can greatly help production. They have larger screens and more processing power than other options. Web-Based and Cloud HMIs let you access your HMI from any device with a browser. This is perfect for remote monitoring and control. Mobile HMIs offer even more freedom. Operators can monitor and control processes on the go, using tablets or smartphones.

The other typs, please check the following:

HMI Types:

| HMI Type | Description | Best For |

|---|---|---|

| Touchscreen HMIs | Easy-to-use, fast, common on shop floors. | General use, quick interaction. |

| Panel-Mount HMIs | Integrated into control cabinets for secure, centralized access. | Secure, centralized control. |

| PC-Based HMIs | Ideal for complex processes with rich data visualization. | Complex data, detailed visualization. |

| Web-Based & Cloud HMIs | Enable remote access from any browser-based device. | Remote monitoring, accessibility. |

| Mobile HMIs | Give operators freedom to monitor and control on the go. | On-the-go monitoring and control. |

I personally prefer touchscreen HMIs, since they are the easiest to use. I have seen older workers struggle with the more advanced technology.

What Key Features Should You Look for in an HMI for Your Plant?

Features are important, but which ones really matter? What should you prioritize when evaluating HMIs?

Prioritize HMIs that offer high-resolution, customizable dashboards2, real-time data3 with alerts, multi-language support, rugged designs for harsher environments, easy SCADA and PLC integration, strong cybersecurity, and room to grow.

When evaluating HMIs, I always tell people to think about usability first! High-resolution displays and dashboards are essential for clear data visualization. Customizable options also allow you to tailor the interface to your specific needs. I have seen plants greatly benefit from being able to modify their HMI.

Real-time data display and event-driven alerts are also critical. Alerts that come up right away can prevent costly downtime and keep operations running smoothly. If you have international teams, multi-language support is a must. A rugged design is needed for almost all industries, as production areas are not the cleanest and most safe places to operate.

Integration capabilities with SCADA and PLC systems ensure your HMI works well with your existing infrastructure. Cybersecurity features are non-negotiable. You should seriously consider the role-based access and encrypted connections. Don't forget to think about the future! Expandability is a key consideration. Can the HMI grow with your operations?

How to Match HMI Capabilities with Plant Needs?

Does one size fit all when it comes to HMIs? What if each manufacturing plant is unique?

Consider your plant’s size and complexity, existing automation infrastructure4, environmental factors, operator skill level, and compliance needs. Make sure the HMI matches them.

Matching HMI capabilities to your plant's needs is about more than just picking the fanciest features; it's about finding the right fit for your situation. If you're operating a larger or multi-line facility, you might need centralized, PC-based HMIs to handle the increased complexity. For instance, a plant I know had multiple production lines, and the operators could easily switch between monitoring various processes. This would not have been possible without a PC-based HMI solution.

Make sure the HMI can talk to your existing devices. Can it work with the PLCs, SCADA, and MES systems you already have? Compatibility can make or break the project, so choose carefully. Think about where the HMI will be used. A food processing area has different requirements than a steel mill.

Also, ask yourself what your operators already know. Does the interface design match their experience and training? Don't overcomplicate things. Last, make sure the HMI can meet any industry-specific rules or regulations. FDA, ISO, and UL certifications are good to have.

Matching HMI to Plant Needs:

- Size & Complexity: Larger plants may need PC-based HMIs.

- Automation Infrastructure: Ensure compatibility with existing PLCs, SCADA, and MES.

- Environmental Factors: Harsh environments need specialized hardware.

- Operator Skill Level: Match the interface design to your team.

- Compliance: Choose HMIs that meet industry standards.

How is Integration with Existing Automation Systems Important?

Thinking of dropping in a new HMI? Keep in mind that seamless integration is essential for consistent production and data flow.

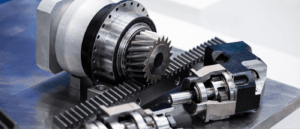

The HMI is only effective if it can talk well with your other automation systems. So, ensure communication with existing PLCs, look for support of open protocols, confirm compatibility with SCADA5, MES, ERP, and IIoT platforms, and check if the HMI supports legacy systems6.

In previous manufacturing projects I worked on, I learned that consistent production and smooth data flow depend on seamless integration. A key component of any good HMI is its ability to communicate effectively with PLCs from big names like Allen-Bradley and Siemens. Be sure it does not only support the big names, but also the other open protocols.

Think about how they work with SCADA, MES, ERP, and IIoT platforms. The easier it is to integrate the new HMI, the better! One facility I worked with upgraded their HMI, it came with all sorts of incompatibility issues. It took months to fix and in the meanwhile greatly set back production.

Ensure support for legacy systems if you're not planning a full overhaul. This keeps the upgrade from disrupting all your existing operations, and keeps things as smooth as possible. Don’t underestimate this step! If you dont have legacy support, be prepared to spend a lot of money on redoing everything.

Integration Checklist:

- Ensure communication with existing PLCs (e.g., Allen-Bradley, Siemens).

- Look for support of open protocols: Modbus, Ethernet/IP, OPC UA, MQTT.

- Confirm compatibility with SCADA, MES, ERP, and IIoT platforms.

- Assess if the HMI supports legacy systems or requires additional middleware.

Remember that new and old technologies do not always work well together. It is important to test them together before making a decision.

Vendor Evaluation and Selection Process

Vendors matter too! Are you making a smart choice when picking an HMI vendor?

Selecting a trusted vendor will ensures support, updates, and system longevity. Compare by feature set, design, reputation, support services, licensing options, and total cost.

In my time, I have seen what happens when a manufacturer doesn't carefully choose a vendor, and it usually doesn't end well. Support, system updates, and the system's expected lifespan are all tied to your vendor. I would recommend that you not only compare the vendors on what they offer, but also the UX design7. Is the interface easy to use? Or is the UX clunky to someone who is not tech savvy?

You also need to consider the support services and training offered. Is there adequate training offered for your team? Is there good online support available for you to read if you get stuck? Warranties and updates are also important to think about, as a broken or outdated system can grind manufacturing to a halt.

You should also think about pricing, it can come in one-time, subscription, or OEM pricing. Lastly, and most imortantly, you must carefully calculate the Total Cost of Ownership. Don't only look at the upfront expense, but the running costs associated with the HMI.

Vendor Evaluation Steps:

- Compare vendors by feature set, UX design, and industry reputation.

- Consider support services: training, software updates, warranties.

- Request a demo or trial to test real-world functionality.

- Evaluate licensing options: one-time, subscription, or OEM pricing.

- Calculate Total Cost of Ownership (TCO), not just the upfront expense.

Sometimes it's worth spending more money to get the best support and service. It is very easy to get frustrated if your vendor is unresponsive.

Estimating Budget and ROI for HMI Investment

Is your HMI investment truly paying off? How can you measure its impact on your bottom line?

Measure the ROI of your HMI investment by considering initial costs, recurring costs, and factors like reduced downtime, improved OEE, faster troubleshooting, and fewer operator errors.

ROI Calculation:

- Initial Costs: Hardware, software licenses, integration, training.

- Recurring Costs: Maintenance, updates, vendor support.

- ROI Factors: Reduced downtime, improved OEE, faster troubleshooting, fewer operator errors.

- Hidden Savings: Less waste, enhanced safety, reduced training time.

The best ROI is seeing happy workers in your factory. It's hard to put a price on a positive workplace.

Case Studies: Choosing the Right HMI in Action

What do successful HMI implementations look like in real-world scenarios?

These case studies show how different plants chose the right HMI to reduce errors, improve sanitation, track compliance, and enable remote monitoring.

Success Stories:

- Automotive: A plant reduced errors by 23% with a high-speed touchscreen HMI.

- Food & Beverage: A dairy chose a rugged HMI for hygienic environments.

- Pharmaceuticals: A PC-based HMI helped track compliance and audit trails.

- Electronics: Mobile HMIs allowed engineers to monitor robotics remotely.

It's helpful to learn from the successes of others. Do your research and see what other companies are doing!

Common Mistakes to Avoid When Selecting an HMI

What are the common pitfalls to watch out for when choosing an HMI?

Avoid choosing based solely on price, ignoring scalability, overlooking cybersecurity, failing to test integration, and not involving operators in the evaluation process.

Common Mistakes:

- Choosing an HMI based solely on price.

- Ignoring long-term scalability needs.

- Overlooking cybersecurity requirements.

- Failing to test integration with your PLC or SCADA.

- Not involving operators in the evaluation process.

Future Trends in HMI Systems for Manufacturing Plants

What's next for HMI technology? How will it continue to evolve?

Expect future HMIs to integrate with IIoT, use edge computing, incorporate augmented reality, offer voice control, and leverage AI for predictive maintenance.

Future Trends:

- IIoT Integration: Connect your HMI to sensors for a smart factory.

- Edge Computing: Process data closer to the machine for speed.

- Augmented Reality (AR): Visualize machine data in real environments.

- Voice-Controlled Interfaces: Hands-free operation.

- AI-Based Predictive Maintenance: Alert operators of future failures.

The future of HMI is very exciting, with so many new technologies on the horizon! I cannot wait to see what happens next.

Conclusion

Choosing the right HMI isn’t just a tech decision—it’s a productivity strategy. By focusing on your plant’s size, complexity, goals, and integration needs, you can select an HMI that enhances visibility, improves safety, and drives real results.

Insight: HMI Selection: What Your Vendor Won't Tell You

I've had cement plant operators curse at me when their $300k HMI crashed during a critical batch. Let's cut through the brochure talk:

The 5 HMI Truths Nobody Admits

Touchscreens Fail Like Clockwork

- Gloves? Sweat? Grease? Saw a petrochemical plant replace 22 screens yearly until we installed industrial keyboards

- 2025 Tip: Look for hybrid touch/button units.

"Real-Time" is a Lie Without:

✅ <5ms scan times (most budget HMIs run at 250ms)

✅ Properly sized network switches

✅ Avoided Windows-based HMIs (yes, even in 2025)Alarm Management is Where HMIs Go to Die

- One client had 1,200 alarms triggering DAILY

- Solution? We:

- Culled 80% as "useless" alerts

- Color-coded remaining 20% by response urgency

Understanding the significance of HMIs can help you optimize your manufacturing processes and improve efficiency. ↩

Customizable dashboards can significantly improve data visualization and user experience, leading to better operational outcomes. ↩

Exploring the impact of real-time data can enhance decision-making and operational efficiency in your plant. ↩

Understanding the role of existing automation infrastructure can help you choose the right HMI for your plant's needs. ↩

Exploring SCADA compatibility can reveal how to enhance your HMI's effectiveness and integration in your operations. ↩

Learning about legacy system support can save you time and money during HMI upgrades, ensuring smooth operations. ↩

Investigating UX design can reveal how user-friendly systems are, which is vital for efficiency and user satisfaction. ↩