Selecting the right industrial component suppliers is a cornerstone of building a reliable and efficient supply chain. Poor supplier choices can lead to delays, quality issues, and unnecessary costs. To help you make informed decisions, here are 8 actionable best practices that streamline the vetting process and ensure you partner with the right suppliers.

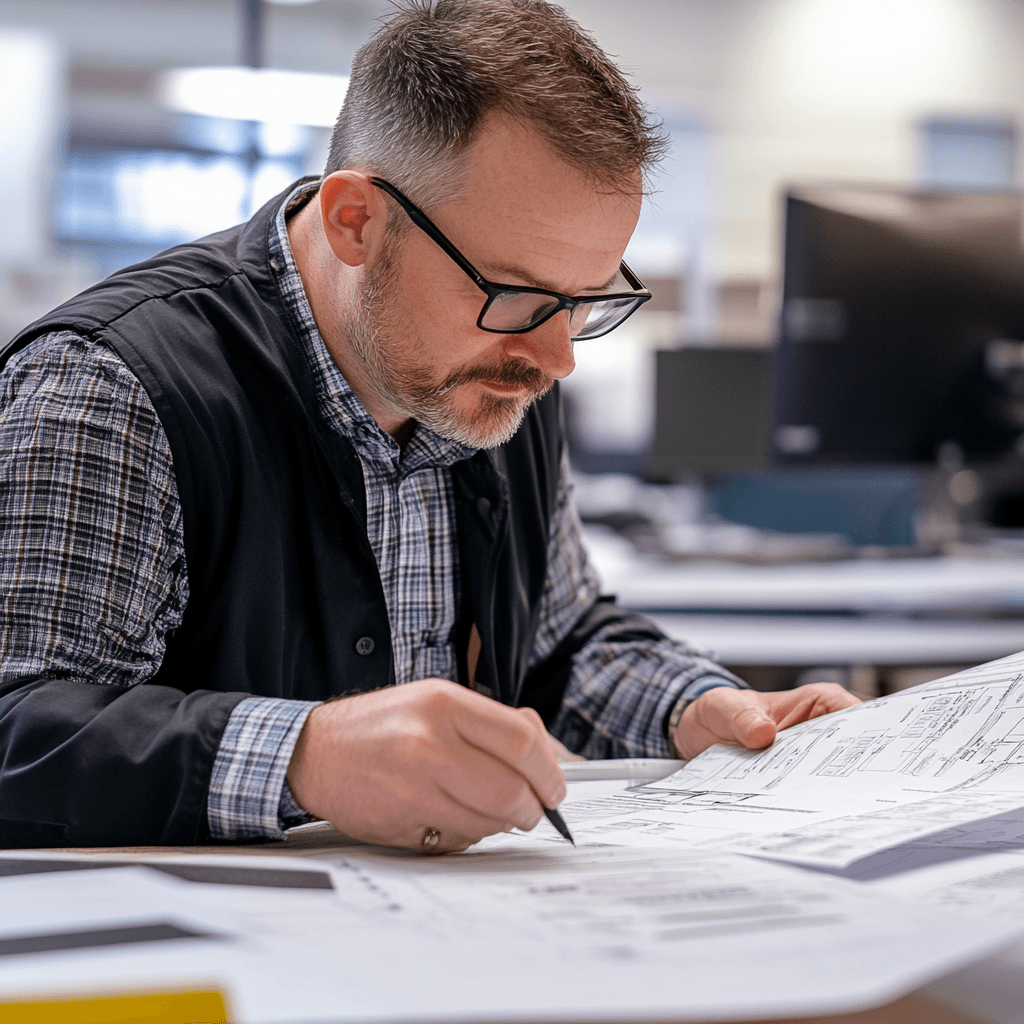

Define Clear Requirements for Industrial Component Suppliers

Before reaching out to potential industrial component suppliers, start by defining your specific needs. A clear understanding of what you require ensures that suppliers align with your expectations from the outset.

Actionable Steps:

- Create a checklist of technical specifications (e.g., power ratings, materials, size tolerances).

- Define must-have certifications like ISO 9001 or CE compliance.

- Set expectations for delivery timelines, budget limits, and warranty terms.

Why It Matters: A clear scope of requirements filters out unsuitable suppliers early, saving time and reducing miscommunication.

Conduct Thorough Market Research

Identifying reliable industrial component suppliers requires a deep dive into the market. This step helps you uncover suppliers that not only meet your needs but also offer competitive advantages.

Actionable Steps:

- Explore Online Directories: Use platforms like ThomasNet or Kompass to identify qualified suppliers.

- Network at Trade Shows: Engage directly with suppliers to understand their offerings and industry presence.

- Benchmark competitors: Research suppliers used by your competitors to gauge their reliability.

Related Question:

What factors should be considered when selecting a supplier?

Key factors include quality, reliability, pricing, product range, technical support, reputation, certifications, warranty policies, and financial stability.

Why It Matters: Effective market research expands your pool of supplier options and uncovers emerging trends or technologies that can benefit your operations.

Evaluate Supplier Capabilities and Capacity

Assessing the capabilities of industrial component suppliers ensures they can deliver consistent quality and meet your production demands.

Actionable Steps:

- Request Documentation: Ask for capability statements outlining production capacity, technology, and experience.

- Verify Scalability: Ensure the supplier can handle increasing volumes or custom requirements.

- Check References: Speak with existing clients to confirm their reliability and quality standards.

Related Question:

Why are site visits important in supplier selection?

Site visits allow you to evaluate a supplier’s operational capabilities, quality control processes, and overall efficiency firsthand.

Why It Matters: Partnering with a capable supplier reduces risks related to supply chain disruptions or product defects.

Assess Financial Stability

The financial health of your industrial component suppliers can directly impact your supply chain’s reliability. Financial instability in a supplier may result in sudden disruptions or quality compromises.

Actionable Steps:

- Review Financial Statements: Request balance sheets and income statements to assess liquidity and profitability.

- Check Credit Ratings: Use third-party tools like Dun & Bradstreet to evaluate financial stability.

- Look for Red Flags: Monitor signs of financial distress, such as ownership changes or excessive debt levels.

Related Question:

How can I assess a supplier's financial stability?

Review financial statements, credit ratings, bank references, and any public financial disclosures to gauge a supplier’s financial health.

Why It Matters: Financially stable suppliers are more likely to sustain long-term partnerships and ensure consistent delivery.

Verify Compliance and Certifications

Certifications validate that industrial component suppliers adhere to industry standards, ensuring quality and regulatory compliance.

Actionable Steps:

- Request certifications like ISO 9001 (quality management) or ISO 14001 (environmental management).

- Verify compliance with industry-specific standards such as RoHS, CE, or UL certifications.

- Use online tools to confirm the validity of certifications through issuing authorities.

Related Question:

How do certifications impact supplier selection?

Certifications like ISO 9001 indicate that a supplier adheres to recognized quality management standards, ensuring consistent product quality.

Why It Matters: Working with certified suppliers minimizes risks related to substandard components or legal penalties.

Conduct Site Visits or Virtual Audits

Site visits allow you to gain firsthand insights into the operational practices of industrial component suppliers, ensuring transparency and reliability.

Actionable Steps:

- Inspect Facilities: Assess production lines, equipment conditions, and storage practices.

- Engage personnel: Speak with managers and workers to understand their problem-solving approaches.

- Request Virtual Tours: If on-site visits aren’t possible, ask for a live video walkthrough.

Related Question:

Why are site visits important in supplier selection?

Site visits allow you to evaluate a supplier’s operational capabilities, quality control processes, and overall efficiency firsthand.

Why It Matters: Partnering with a capable supplier reduces risks related to supply chain disruptions or product defects.

Negotiate Terms and Build Relationships

Strong relationships with industrial component suppliers pave the way for better terms and smoother collaboration.

Actionable Steps:

- Negotiate Pricing: Explore discounts for bulk purchases or long-term contracts.

- Define Clear Terms: Set clear expectations for delivery timelines, payment schedules, and warranties in writing.

- Foster Trust: Maintain consistent communication to build a strong partnership.

When Uni Regal Corp. Ltd. Can Help:

At Uni Regal, we prioritize transparent and collaborative relationships with clients. By offering flexible terms and robust support, we ensure every partnership is mutually beneficial.

Leverage Technology for Supplier Management

Digital tools can simplify the management of industrial component suppliers, improving efficiency and decision-making.

Actionable Steps:

- Adopt Procurement Platforms: Use tools like SAP Ariba to streamline sourcing and contract management.

- Track Supplier Performance: Use analytics to monitor delivery times, defect rates, and compliance.

- Centralize Communication: Platforms like Slack or Microsoft Teams facilitate real-time updates and issue resolution.

Related Question:

What role does technology play in modern supplier management?

Technology enhances visibility across the supply chain, improves communication, facilitates data-driven decisions, and helps manage risks effectively.

Why It Matters: Leveraging technology reduces manual errors and enables proactive management of supplier relationships.

Conclusion

Vetting new industrial component suppliers doesn’t have to be overwhelming. By following these 8 best practices, you can ensure reliable partnerships, maintain quality standards, and streamline your supply chain. Whether it’s through defining clear requirements, conducting site visits, or leveraging technology, these strategies provide a roadmap to success.

Uni Regal Corp. Ltd. embodies these principles, delivering high-quality components backed by robust support and industry expertise. Partner with us to take your industrial automation to the next level.