Manufacturing is undergoing a revolution driven by advancements in automation technologies, fundamentally transforming how factories operate. This article highlights 8 key automation technologies that are shaping the future of manufacturing, enhancing production efficiency, reducing costs, and optimizing quality control.

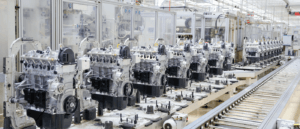

Industrial Robots: Core Automation Technologies in Action

Industrial robots have become indispensable in manufacturing, widely used for assembly, welding, material handling, and quality inspection. According to the International Federation of Robotics (IFR), global installations of industrial robots reached 523,000 units in 2023, marking a record high.

Advantages: Industrial robots work continuously, minimizing human error and significantly boosting production efficiency. In the automotive industry, for instance, robotic welding can achieve a precision rate of 99.9%.

Example: Tesla employs thousands of robots in its factories, automating much of the production line to reduce cycle times and increase output.

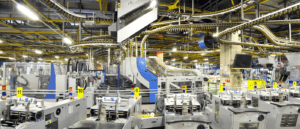

Internet of Things (IoT): The Backbone of Smart Automation Technologies

The Internet of Things (IoT) connects devices throughout a factory, enabling real-time data communication and paving the way for "smart manufacturing." According to McKinsey Global Institute (McKinsey), IoT is expected to generate $1.2 trillion in economic value for manufacturing over the next decade.

Advantages: With IoT sensors monitoring equipment health, companies can reduce unplanned downtime. For example, a global packaging firm achieved a 20% reduction in equipment failures by implementing predictive maintenance using IoT.

Example: Siemens' “Digital Factory” leverages IoT for real-time monitoring and remote control, leading to a 10% increase in production output.

Artificial Intelligence (AI): Smarter Automation Technologies for Efficiency

Artificial Intelligence (AI) is pushing manufacturing towards smart production, optimizing workflows, enhancing quality control, and analyzing production data. Gartner projects that by 2025, more than 50% of large manufacturers will widely use AI (Gartner).

Advantages: AI algorithms can analyze production data to identify inefficiencies and suggest improvements. An electronics manufacturer saved millions annually by leveraging AI for process optimization.

Example: Samsung employs AI in quality control to detect even microscopic defects, reducing the defect rate by 30%.

Collaborative Robots (Cobots): User-Friendly Automation Technologies

Collaborative robots (Cobots) are designed to work safely alongside humans and are increasingly used for tasks like electronics assembly and small-scale manufacturing. The cobots market is expected to reach $12 billion by 2028 (MarketsandMarkets).

Advantages: Cobots are easy to program and adaptable to changing tasks, making them ideal for dynamic production environments. An electronics firm increased productivity by deploying cobots for multi-tasking operations.

Example: Universal Robots from Denmark supply thousands of cobots to small and medium-sized enterprises, boosting output while reducing worker fatigue.

AGVs and AMRs: Mobile Automation Technologies for Logistics

Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs) streamline material handling and logistics within factories, optimizing internal workflows. By using these automation technologies, companies can improve inventory management and reduce manual labor costs.

Advantages: AMRs autonomously navigate and avoid obstacles, selecting the most efficient paths. A logistics giant reported a 15% increase in fulfillment efficiency using AMRs (Logistics Industry News).

Example: Amazon uses tens of thousands of AGVs in its distribution centers, cutting order processing times and boosting efficiency.

Smart Sensors: Foundational Automation Technologies for Monitoring

Smart sensors monitor variables like temperature, pressure, and vibration, providing real-time data for predictive maintenance and energy optimization. Deloitte reports that factories using smart sensors can reduce maintenance costs by 10-15% (Deloitte).

Advantages: Smart sensors automate data collection and analysis, enhancing operational efficiency. A heavy industry firm saved millions annually through energy management improvements using these sensors.

Example: Siemens uses thousands of smart sensors in its factories to optimize processes and prevent equipment failures in real time.

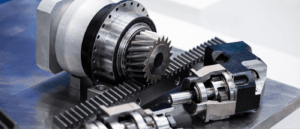

Machine Vision Systems: Precision Automation Technologies

Machine vision systems employ cameras and image processing software for quality control, ensuring precise inspection in industries like electronics and food packaging. The global machine vision market is projected to exceed $15 billion by 2026 (Allied Market Research).

Advantages: These systems detect defects within milliseconds, improving quality assurance accuracy. A food packaging company enhanced product quality, achieving a 99% pass rate by implementing machine vision.

Example: Foxconn utilizes machine vision systems extensively, preventing millions of defective products from reaching consumers each year.

Additive Manufacturing (3D Printing): Game-Changing Automation Technologies

Additive manufacturing, or 3D printing, constructs parts layer by layer and is transforming industries like aerospace, healthcare, and automotive. The 3D printing market is projected to grow to $30 billion by 2025 (Statista).

Advantages: 3D printing reduces development cycles and lowers costs. Boeing saves thousands per aircraft by manufacturing parts with additive manufacturing.

Example: General Electric (GE) uses 3D printing for gas turbine components, halving development time.

Uni Regal Corp. Ltd: Your Automation Parts Supplier

Implementing these cutting-edge automation technologies requires high-quality parts and equipment. Uni Regal Corp. Ltd offers a comprehensive range of industrial automation solutions, including PLCs, servo motors, and HMIs from top brands. With our extensive inventory and fast delivery, you can seamlessly upgrade your manufacturing processes to meet the demands of modern industry.

Conclusion

These transformative automation technologies are reshaping the manufacturing landscape. From industrial robots to additive manufacturing, each technology provides opportunities to enhance efficiency and competitiveness. By partnering with Uni Regal, you gain access to high-quality parts and support to keep your operations running smoothly and efficiently.