Wholesale Mitsubishi PLC Parts All in One Place

At Uni Regal Corp., we are your go-to source for high-performance Mitsubishi PLC parts. Whether you prefer our STOCKING components or wish to customize your solutions, our precision-engineered products are designed to excel in diverse applications. Choose CONTROLLERPART.COM to elevate your projects to new heights.

15

Years of experience

Your Reliable Source for Mitsubishi PLCs

“We Build Excellence with Top-Quality Materials and Expertise”

Welcome to Uni Regal Corp., your trusted distributor of high-quality industrial automation parts. We specialize in providing durable and efficient components from leading brands, tailored to meet the rigorous demands of various industries.

Our extensive range includes PLCs, HMIs, servo motors, inverters, relays, and breakers, available in multiple forms such as panels, modules, and compact units. These components are ideal for optimizing manufacturing processes, ensuring precise control, and enhancing productivity across automotive, oil and gas, and large-scale manufacturing sectors.

- Tailored Solutions: Whether you need a small batch or bulk orders, we customize to meet your specific needs.

- Expert Team: Our professionals bring decades of experience in the industrial automation sector.

- Competitive Pricing: As a multi-branded distributor, we offer the best prices and quality.

- Comprehensive Service: Our diverse inventory and processing capabilities ensure complete satisfaction.

- Prompt Delivery: Our efficient logistics guarantee timely delivery of your orders.

- Guaranteed Satisfaction: We are committed to quality and transparent communication, ensuring a seamless experience.

Trusted Mitusbishi PLCs Supplier

Reliability, efficiency, and superior performance in demanding industrial environments

Customize Your Mitsubishi PLCs with Uni Regal Corp.

Experience a streamlined customization process with UniRegal Automation. Our efficient four-step method ensures you receive comprehensive support at every stage, eliminating typical obstacles:

Step 1.

Understanding Your Operation

Share the specifics of your operation, including details such as system requirements, operational conditions, average load capacities, overall system voltage, and performance metrics.

Step 2.

Defining Your Application

Specify the industrial automation processes you aim for, whether it’s manufacturing automation, process control, robotic integration, machine safety, or any other specialized process.

Step 3.

Choosing Mitsubishi PLC Solutions

Select the exact automation components needed, whether it involves PLCs, HMIs, servo motors, inverters, or any other automation equipment.

Step 4

Submitting Your Requirements

Provide your request and detailed specifications, and quantity, ensuring the final components align perfectly with your perspective.

Consult with our Engineers

Frequently asked questions

Key Facts About Our Mitsubishi PLCs

To ensure you have all the necessary information, here are some key facts about our Mitsubishi PLCs:

No, shipping fees apply for Mitsubishi PLC orders.

If your order is delayed for more than a week, please contact Uni Regal Corp. customer care through our website for assistance. Delays can occur due to unavoidable circumstances, but we will keep you informed.

While rare, if any products are damaged during shipping, please contact our customer care. We ensure all products are well-packaged, but if damage occurs, we will guide you on the next steps.

Typically, orders are delivered within 1 weeks. However, if there are issues with the shipping company, it may take up to 15 working days.

Our Mitsubishi PLCs come in various models with specific configurations. Customizations are available to meet your specific industrial requirements.

Mitsubishi PLCs are high-quality, reliable, and designed for industrial applications. They enhance automation processes and improve operational efficiency. Uni Regal Corp. ensures you receive top-quality products backed by excellent customer service.

Yes, Mitsubishi PLCs are designed to be compatible with various industrial automation systems, ensuring seamless integration and optimal performance.

Yes, we offer comprehensive training sessions and resources to help your team effectively implement and utilize Mitsubishi PLCs in your operations.

Your Definitive Guide to Procuring Mitsubishi PLCs

Mitsubishi PLCs find diverse applications in manufacturing, process control, robotics, and various industrial sectors.

Whether you’re contemplating importing Mitsubishi PLCs for your projects or entering the realm of local wholesale distribution, this guide is meticulously tailored to equip you with all the essential knowledge you require.

Table of Contents

WHAT ARE MITSUBISHI PLCS?

Mitsubishi PLCs (Programmable Logic Controllers) are advanced automation components designed to control and monitor industrial machinery and processes. They consist of a central processing unit (CPU), input/output (I/O) modules, and various communication interfaces, allowing for precise and reliable automation control.

Mitsubishi PLCs are known for their robustness, flexibility, and scalability. They can handle a wide range of applications, from simple machine control to complex process automation, making them ideal for various industries including manufacturing, automotive, and energy.

Due to their exceptional performance and reliability, Mitsubishi PLCs enhance operational efficiency, reduce downtime, and ensure consistent production quality. These controllers are integral to modern industrial automation, providing a cost-effective and dependable solution for improving process control and productivity.

Specifications of Mitsubishi PLCs

Mitsubishi PLCs are designed to meet the diverse needs of industrial automation with their robust specifications and advanced features. Below are some key specifications:

CPU Modules

- Processing Speed: Up to 0.32 µs per instruction

- Memory: From 8 KB to 64 MB

- I/O Points: 16 to 4096 points

- Communication Ports: Ethernet, RS-232, RS-485, USB

- Programming Languages: Ladder Logic, Structured Text, Function Block Diagram

Power Supply

- Input Voltage: 100-240 VAC or 24 VDC

- Power Consumption: 20W to 60W

I/O Modules

- Digital Inputs: 24VDC, 110VAC, 220VAC

- Digital Outputs: Relay, Transistor

- Analog Inputs: Voltage (0-10V), Current (4-20mA)

- Analog Outputs: Voltage (0-10V), Current (4-20mA)

- Specialty Modules: High-speed counters, Temperature control, Motion control

Communication

- Protocols Supported: Ethernet/IP, Modbus TCP, Profibus, CC-Link, DeviceNet

- Network Topologies: Star, Bus, Ring

ENVIRONMENTAL SPECIFICATIONS

- Operating Temperature: -20°C to 60°C

- Storage Temperature: -40°C to 85°C

- Humidity: 5% to 95% RH (non-condensing)

- Vibration Resistance: 5 Hz to 9 Hz at 3.5 mm amplitude, 9 Hz to 150 Hz at 9.8 m/s² acceleration

CERTIFICATIONS AND STANDARDS

- Certifications: CE, UL, CSA

- Standards: IEC 61131-2, IEC 61000-6-2, IEC 61000-6-4

These specifications ensure that Mitsubishi PLCs can handle various industrial applications with high reliability and performance.

Optimization Techniques

- Optimize Scan Time: Optimize the PLC scan time by removing unnecessary instructions and optimizing the logic sequence.

- Efficient Use of Resources: Use memory and processing resources efficiently by cleaning up unused variables and optimizing the code.

- Monitor Performance: Continuously monitor the PLC performance to identify and address potential issues before they escalate.

Safety Considerations

- Follow Safety Protocols: Always follow safety protocols and guidelines while installing, programming, or maintaining PLCs.

- Emergency Stops: Ensure emergency stop mechanisms are in place and functioning correctly.

- Isolation Procedures: Follow proper isolation procedures when working on or near PLC systems to prevent accidental energization.

Tips for Using Mitsubishi PLCs

Proper Installation

- Ensure Proper Grounding: Properly ground the PLC to avoid electrical noise and potential damage.

- Correct Mounting: Mount the PLC in a well-ventilated, clean, and dry location to prevent overheating and contamination.

- Secure Connections: Ensure all wiring connections are safe and properly insulated to avoid short circuits and electrical faults.

Programming Best Practices

- Use Structured Programming: Organize your code using structured programming techniques like subroutines and function blocks for easier debugging and maintenance.

- Comment Your Code: Add comments to your code to explain the functionality of different sections. This helps in understanding the logic and makes future modifications easier.

- Regular Backups: Keep regular backups of your PLC programs to prevent data loss in case of hardware failure or accidental deletions.

Maintenance and Upkeep

- Regular Inspections: Perform regular visual inspections of the PLC and its components to check for signs of wear, corrosion, or damage.

- Update Firmware: Keep the PLC firmware up to date to benefit from the latest features and security patches.

- Clean Periodically: Clean the PLC and its surrounding environment to prevent dust and debris buildup, which can affect performance.

Troubleshooting Tips

- Diagnostic Tools: Utilize built-in diagnostic tools and software to identify and troubleshoot issues quickly.

- Error Codes: Familiarize yourself with common error codes and their meanings to expedite troubleshooting.

- Check Power Supply: Ensure the power supply is stable and within the specified range to avoid unexpected shutdowns or malfunctions.

Advantages of Mitsubishi PLCs

Mitsubishi PLCs (Programmable Logic Controllers) offer numerous advantages, making them a preferred choice for industrial automation applications. Here are some key benefits:

1. High Reliability

- Robust Design: Built to withstand harsh industrial environments, Mitsubishi PLCs are known for their durability and long-term reliability.

- Consistent Performance: They provide consistent and stable performance, reducing downtime and maintenance costs.

2. Advanced Functionality

- Versatile Programming: Support for multiple programming languages, including Ladder Logic, Structured Text, and Function Block Diagrams, allows for flexible and efficient programming.

- High-Speed Processing: Capable of handling high-speed operations and complex control tasks with fast processing speeds.

3. Scalability

- Modular Design: Mitsubishi PLCs offer a modular design, allowing for easy expansion and customization to meet the specific needs of various applications.

- Wide Range of Models: From compact PLCs for small-scale applications to high-performance models for complex automation systems, Mitsubishi provides a comprehensive range of options.

4. Comprehensive Communication

- Multiple Communication Protocols: Support for various communication protocols, such as Ethernet/IP, Modbus TCP, Profibus, and CC-Link, ensures seamless integration with other devices and systems.

- Remote Monitoring and Control: Advanced networking capabilities enable remote monitoring and control, enhancing operational efficiency and flexibility.

5. User-Friendly Interface

- Intuitive Software: Mitsubishi PLCs come with user-friendly programming software that simplifies the development and troubleshooting of automation solutions.

- Clear Documentation: Comprehensive documentation and support materials make it easier for users to get started and effectively use the PLCs.

6. Energy Efficiency

- Low Power Consumption: Designed to operate efficiently, Mitsubishi PLCs help reduce energy consumption and lower operational costs.

- Eco-Friendly Features: Some models include eco-friendly features that contribute to sustainable industrial practices.

7. Enhanced Safety

- Built-In Safety Functions: Mitsubishi PLCs include built-in safety features such as emergency stops, fault detection, and safe state operations to protect equipment and personnel.

- Compliance with Standards: Adherence to international safety and quality standards ensures that the PLCs meet stringent regulatory requirements.

8. Comprehensive Support

- Technical Assistance: Mitsubishi offers extensive technical support, including training, troubleshooting, and online resources to help users maximize the benefits of their PLCs.

- Global Network: A global support network ensures that assistance is available wherever the PLCs are used.

9. Cost-Effectiveness

- Competitive Pricing: Mitsubishi PLCs offer a competitive price-performance ratio, providing advanced features and reliability at a reasonable cost.

- Long-Term Savings: The reliability and durability of Mitsubishi PLCs lead to long-term savings on maintenance and replacement costs.

10. Customization Options

- Tailored Solutions: Mitsubishi PLCs can be customized to meet specific industrial requirements, providing tailored solutions for unique applications.

- Flexible Configurations: The ability to configure the PLCs to match the real demand to ensure optimal performance and efficiency.

In summary, Mitsubishi PLCs provide high reliability, advanced functionality, scalability, comprehensive communication, user-friendly interfaces, energy efficiency, enhanced safety, thorough support, cost-effectiveness, and customization options. These advantages make them an ideal choice for numerous industrial automation applications.

Applications of Mitsubishi PLCs

Mitsubishi PLCs (Programmable Logic Controllers) are versatile and reliable automation controllers used in a wide range of industries. Here are some key applications:

1. Manufacturing Automation

- Assembly Lines: Mitsubishi PLCs control and coordinate automated assembly lines, ensuring precise operations and synchronization of various processes.

- Robotics: PLCs manage robotic arms and other automated machinery, enhancing efficiency and accuracy in manufacturing tasks.

- Quality Control: Used in quality control systems to monitor and adjust manufacturing parameters, ensuring product consistency and reducing defects.

2. Automotive Industry

- Production Lines: Control systems for automotive production lines, managing everything from body welding to final assembly.

- Testing Stations: Automate testing and inspection stations to ensure vehicles meet safety and performance standards.

- Paint Shops: PLCs control the automated paint application processes, ensuring uniform coverage and quality.

3. Energy and Utilities

- Power Generation: Manage operations in power plants, including turbine control, boiler management, and energy distribution.

- Water Treatment: Automate water and wastewater treatment processes, ensuring efficient and reliable treatment and distribution.

- Renewable Energy: Control systems for renewable energy installations, such as wind turbines and solar power plants.

4. Oil and Gas

- Drilling Operations: PLCs manage drilling rigs and associated equipment, ensuring safe and efficient operations.

- Pipeline Monitoring: Automate monitoring and control of oil and gas pipelines, ensuring safe transportation and minimizing risks.

- Refinery Processes: Control complex processes in refineries, including distillation, cracking, and blending operations.

5. Food and Beverage

- Processing Lines: Automate food and beverage processing lines, ensuring hygiene, consistency, and efficiency.

- Packaging: Manage automated packaging systems, ensuring accurate and efficient packing, labeling, and palletizing.

- Temperature Control: Control temperature and humidity in storage and production areas to maintain product quality.

6. Building Automation

- HVAC Systems: Control heating, ventilation, and air conditioning systems to maintain optimal indoor environments.

- Lighting Control: Automate lighting systems for energy efficiency and convenience.

- Security Systems: Integrate and control building security systems, including access control, surveillance, and alarm systems.

7. Pharmaceuticals

- Production Control: Automate pharmaceutical production lines to ensure precise dosing, mixing, and packaging.

- Compliance Monitoring: Ensure compliance with industry standards and regulations through automated monitoring and reporting.

- Environmental Control: Manage cleanroom environments to maintain the stringent conditions required for pharmaceutical manufacturing.

8. Material Handling

- Conveyor Systems: Control conveyor belts and sorting systems in warehouses and distribution centers for efficient material handling.

- Automated Storage and Retrieval: Manage automated storage and retrieval systems (AS/RS) for optimized inventory management.

- Cranes and Hoists: Control industrial cranes and hoists, ensuring safe and efficient lifting and transportation of materials.

9. Textile Industry

- Looms and Knitting Machines: Automate looms and knitting machines to enhance production speed and fabric quality.

- Dyeing Processes: Control dyeing machines to ensure uniform color and quality in textile products.

- Finishing Operations: Manage finishing processes, including cutting, sewing, and packaging, to streamline textile production.

10. Transportation and Infrastructure

- Traffic Management: Control traffic lights and signaling systems for efficient traffic flow and safety.

- Railway Automation: Automate railway control systems, including train scheduling, signaling, and safety systems.

- Airport Systems: Manage airport systems, including baggage handling, passenger information, and security systems.

Mitsubishi PLCs are integral to modern industrial automation, providing reliable and efficient control across diversified applications. Their flexibility, scalability, and robust performance make them a preferred choice for enhancing productivity and operational efficiency.

How to Choose the Right Mitsubishi PLC parts?

Selecting the appropriate Mitsubishi PLC for your application is crucial to ensure optimal performance and efficiency. Here are key factors to consider:

1. Determine Your Application Requirements

- Control Needs: Identify the specific control tasks (e.g., logic control, process control) that the PLC needs to perform.

- I/O Requirements: Calculate the number and types of input/output points required, including digital, analog, and specialty I/Os.

- Performance: Assess the necessary processing speed and memory capacity based on the complexity of your application.

2. Evaluate Environmental Conditions

- Operating Environment: Consider the environmental conditions where the PLC will be installed, such as temperature range, humidity, and exposure to dust or chemicals.

- Durability: Ensure the PLC can withstand the environmental stresses it will encounter, such as vibration, shock, and electrical noise.

3. Choose the Right PLC Series

- Compact Series: Suitable for smaller applications with limited I/O requirements and space constraints.

- Modular Series: Ideal for medium to large applications needing flexibility and expandability.

- High-Performance Series: Best for complex applications requiring high-speed processing and advanced functionalities.

4. Consider Communication Needs

- Network Compatibility: Ensure the PLC supports the communication protocols used in your system (e.g., Ethernet/IP, Modbus TCP, Profibus, CC-Link).

- Remote Monitoring: If remote monitoring and control are necessary, select a PLC with the appropriate networking capabilities.

5. Assess Programming and Integration

- Programming Languages: Verify that the PLC supports the programming languages you are familiar with or require, such as Ladder Logic, Structured Text, or Function Block Diagram.

- Integration: Ensure the PLC can seamlessly integrate with your existing systems and devices, including HMIs, SCADA systems, and other automation components.

6. REVIEW SAFETY AND COMPLIANCE

- Certifications: Check for necessary certifications (e.g., CE, UL, CSA) to ensure compliance with industry standards and regulations.

- Safety Features: Look for built-in safety features, such as emergency stops, fault detection, and safe state operations.

7. Budget Considerations

- Cost-Effectiveness: Balance the PLC cost with the features and performance. Consider long-term benefits such as reliability, ease of maintenance, and energy efficiency.

- Scalability: Choose a PLC that allows for future expansion and upgrades, minimizing the need for costly replacements as your system grows.

8. Vendor Support and Service

- Technical Support: Ensure the vendor provides robust technical support and resources, including training, documentation, and troubleshooting assistance.

- Warranty and Service: Check the warranty and service options available to ensure ongoing support and protection for your investment.

By carefully evaluating these factors, you can select the right Mitsubishi PLC that meets your specific industrial automation needs, ensuring efficiency, reliability, and scalability for your operations.

8. Software Tools

- GX Works3: Advanced programming and diagnostics.

- SCADA Integration: Comprehensive process control and data analysis.

9. Energy Management

- Power Monitoring: Track and optimize energy use.

- Load Management: Efficient energy usage programs.

10. Maintenance and Diagnostics

- Predictive Maintenance: Built-in diagnostics for maintenance.

- Fault Analysis: Custom routines for quick issue resolution.

Mitsubishi PLCs provide the flexibility and performance needed for efficient, reliable automation solutions.

Customizable Mitsubishi PLC Solutions

Mitsubishi PLCs (Programmable Logic Controllers) are renowned for their flexibility and adaptability, making them ideal for many industrial applications. Here are some ways you can customize Mitsubishi PLC solutions to meet your specific needs:

1. Modular Design

- Flexible Configuration: Add/remove modules as needed.

- Expansion Options: Easily add I/O and communication modules.

2. Tailored Programming

- Custom Logic: Develop specific control logic.

- Application Functions: Create functions for unique process requirements.

3. Advanced Communication

- Network Integration: Use Ethernet/IP, Modbus TCP, Profibus, and CC-Link.

- Remote Monitoring: Implement remote control capabilities.

4. Specialized Modules

- High-Speed Processing: Use high-speed counter and motion control modules.

- I/O Options: Mix analog and digital I/O modules.

5. Environmental Adaptation

- Ruggedized Models: For harsh environments.

- Conformal Coating: Protect components from moisture and dust.

6. Safety Integration

- Safety Modules: Enhance machine safety with emergency stops and interlocks.

- Compliance: Meet safety standards like CE and UL.

7. User Interface Customization

- HMI Integration: Customizable HMI screens for control and monitoring.

- Access Levels: Configure security for different user roles.

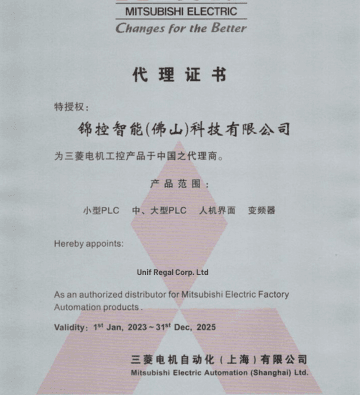

How We Ensure the Quality of Mitsubishi PLCs

At Uni Regal Corp., your assurance of quality is paramount. We dedicate ourselves to ensuring that the Mitsubishi PLCs you receive meet the highest industry standards. Through comprehensive testing protocols, including mid-production and final inspections, we ensure every PLC you get is flawless and surpasses the strict quality benchmarks you expect. Our commitment is to deliver excellence, consistently providing products that exceed your expectations and enhance the success of your projects.

We inspect all incoming materials to ensure they meet our strict quality standards before shipping.

We conduct rigorous in-process testing on items, ensuring each PLC is without any problems.

Each PLC undergoes a thorough final inspection to confirm it meets all specifications and industry standards.

Perform Regular quality assurance audits to ensure continuous adherence to customer satisfaction.

In summery

Navigating the selection of Mitsubishi PLCs can be a seamless process with the correct information at your disposal. At Uni Regal Corp., we ensure you have the knowledge and options to make informed decisions. Our extensive range of PLCs is crafted to cater to various industrial applications, ensuring you find the perfect match for your project’s needs.

Our dedicated team is committed to providing you with personalized assistance, guiding you every step of the way in identifying the best-fit PLC solution for your business. We prioritize your requirements and objectives, ensuring that our solutions meet and exceed your expectations, driving your business toward greater efficiency and success.

Boost Performance with Custom Mitsubishi PLCs!

Maximize efficiency with UniRegal Automation’s Custom Mitsubishi PLCs. Get premium, cost-effective solutions tailored to your project needs. Order now for enhanced performance and profitability!