Siemens PLC Solutions

Looking to enhance your automation systems with cutting-edge technology? Explore how our Siemens PLC solutions, customized for your specific needs, can elevate your operational efficiency. Experience unmatched reliability and performance, designed to meet the demands of your industrial applications. Don’t miss the opportunity to optimize your processes. Contact us today to transform your automation systems with Siemens PLCs!

15

Years of experience

Your Trusted Source for Siemens PLCs

“We Craft Excellence with Premium Components and Expert Solutions”

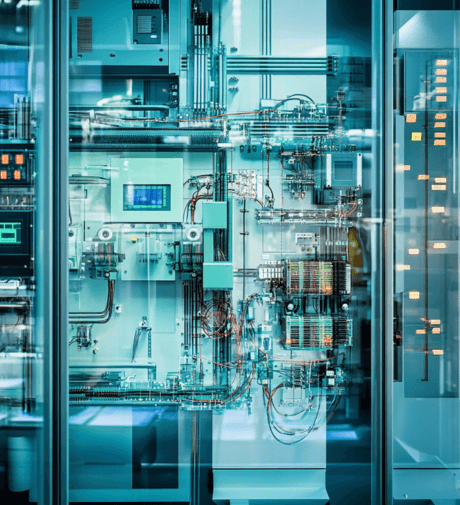

Siemens PLCs are renowned for their superior control capabilities and robust performance. However, the complexity of industrial environments demands solutions that go beyond standard configurations. At Uni Regal Corp., we specialize in providing Siemens PLCs that are expertly configured to meet the unique requirements of your industrial processes, ensuring seamless integration and optimized performance.

Our focus on Siemens PLCs is driven by their versatility and ability to handle a wide range of automation tasks with precision and reliability. Whether you need modules, CPUs, power supplies, or communication processors, our comprehensive selection caters to diverse industrial applications, promising unmatched operational efficiency.

Experience the Uni Regal Corp., advantage with our tailored Siemens PLC solutions, designed to your exact specifications in terms of functionality, scalability, and integration. Trust our extensive industry expertise to deliver automation solutions that not only meet but exceed your expectations. Connect with us today to elevate your automation systems with our specialized, high-quality Siemens PLCs.

- Tailored Solutions: Whether for small or large-scale orders, we customize to meet your precise requirements.

- Expert Team: Our specialists bring decades of expertise in the industrial automation field.

- Competitive Pricing: As a leading multi-branded distributor, we deliver top-quality products at the best prices.

- Comprehensive Service: Our extensive inventory and processing capabilities ensure complete customer satisfaction.

- Prompt Delivery: Our streamlined logistics ensure your orders are delivered on time, every time.

- Guaranteed Satisfaction: We are dedicated to quality and transparent communication, ensuring a seamless and reliable experience.

Trusted Siemens PLCs Supplier

Dependable, efficient, and engineered for exceptional performance in the most demanding industrial environments.

Customize Your Siemens PLCs Solutions with Uni Regal Corp.

Experience a streamlined customization process with Uni Regal Corp. Our efficient four-step method ensures you receive comprehensive support at every stage, eliminating typical obstacles:

Step 1.

Understanding Your Operation

Share the specifics of your operation, including system requirements, environmental conditions, average load capacities, overall system voltage, and key performance metrics.

Step 2.

Defining Your Application

Outline the industrial automation processes you are targeting, whether it’s manufacturing automation, process control, robotic integration, machine safety, or another specialized application.

Step 3.

Choosing Siemens PLC Solutions

Select the specific automation components required, whether it’s PLCs, HMIs, power supplies, communication modules, or other Siemens automation equipment.

Step 4

Submitting Your Requirements

Submit your detailed specifications and quantities, ensuring the final components perfectly align with your operational needs.

Consult with our Engineers

Frequently asked questions

Key Facts About Our Siemens PLCs

To ensure you have all the essential information, here are some key facts about our Siemens PLCs:

We accept various payment methods, including bank transfers and major credit cards, to ensure a smooth transaction process.

Once your order is shipped, we will provide a tracking number via email. You can use this number to monitor the delivery status through the carrier’s website.

Yes, we offer a return policy for products that do not meet your specifications. Please contact customer care within 7 days of receiving your order for assistance with returns.

Yes, all Siemens PLCs come with a manufacturer’s warranty. The warranty period may vary depending on the model, so please check the specific product details.

We provide comprehensive technical support, including installation guidance and troubleshooting. Our expert team is available to assist with any questions or issues.

Yes, we offer competitive pricing and bulk discounts for large orders. Contact us to discuss your specific needs and receive a customized quote.

Our team can help you select the right Siemens PLC based on your application’s requirements, including system complexity, scalability, and environmental conditions.

Yes, Siemens PLCs can be customized to comply with specific industry standards and regulations. Contact our team to discuss your requirements and ensure the PLCs meet your exact specifications.

Your Ultimate Guide to Acquiring Siemens PLCs

Explore the essential role Siemens PLCs play in optimizing industrial automation processes, from manufacturing automation to complex process control systems. Learn how these PLCs enhance the efficiency and reliability of your operations, demonstrating their flexibility across various industrial environments.

This comprehensive guide also examines the adaptability of Siemens PLCs in sectors ranging from robotics integration to machine safety, highlighting their crucial role in maintaining smooth and effective operations. Whether you’re planning a new automation project or considering bulk purchases, our guide provides key insights to help you select the perfect Siemens PLCs, tailored to meet your specific industrial needs with precision.

Table of Contents

What are Siemens PLCs?

Siemens PLCs (Programmable Logic Controllers) are robust industrial control systems designed to automate complex processes in manufacturing and other industries. These controllers are built on a modular architecture, allowing for flexible configurations and easy scalability to meet various industrial needs.

Siemens PLCs are known for their high reliability, precision, and performance, making them suitable for a wide range of applications, including process control, machine automation, and robotics. Their ability to handle demanding tasks with accuracy and consistency makes them indispensable in industries where operational efficiency and control are paramount.

These PLCs are equipped with advanced features such as integrated communication capabilities, extensive I/O options, and powerful processing units, ensuring seamless integration and optimal performance in any automation system. Siemens PLCs are essential for businesses aiming to enhance their production processes and achieve higher levels of automation.

Specifications of Siemens PLCs

Siemens PLCs are engineered to meet the rigorous demands of industrial automation, offering robust specifications and advanced features. Below are some key specifications:

CPU Modules

- Processing Speed: Up to 1 ns per instruction

- Memory: From 50 KB to 2 MB

- I/O Points: 64 to 65,536 points

- Communication Ports: Profinet, RS-232, RS-485, Ethernet

- Programming Languages: Ladder Logic, Structured Text, Function Block Diagram, Sequential Function Chart

Power Supply

- Input Voltage: 24 VDC, 48 VDC, 120-230 VAC

- Power Consumption: 10W to 100W

I/O Modules

- Digital Inputs: 24VDC, 110VAC, 230VAC

- Digital Outputs: Relay, Transistor, Triac

- Analog Inputs: Voltage (±10V), Current (0-20mA)

- Analog Outputs: Voltage (±10V), Current (0-20mA)

- Specialty Modules: High-speed counters, PID controllers, Motion control, Safety modules

Communication

- Protocols Supported: Profinet, Profibus, Modbus TCP, EtherNet/IP, AS-Interface

- Network Topologies: Star, Line, Ring, Mesh

ENVIRONMENTAL SPECIFICATIONS

- Operating Temperature: -25°C to 70°C

- Storage Temperature: -40°C to 85°C

- Humidity: 5% to 95% RH (non-condensing)

- Vibration Resistance: 5 Hz to 8 Hz at 3.5 mm amplitude, 8 Hz to 200 Hz at 9.8 m/s² acceleration

CERTIFICATIONS AND STANDARDS

- Certifications: CE, UL, CSA, ATEX

- Standards: IEC 61131-2, IEC 61508, IEC 62061, ISO 13849

These specifications ensure that Siemens PLCs can support a wide range of industrial applications with exceptional reliability and performance.

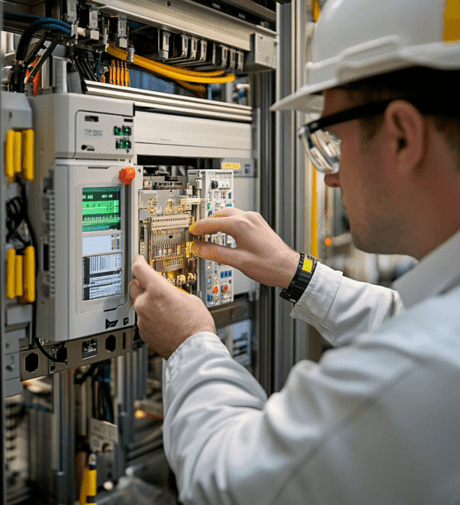

Guidelines for the Safe Use of Siemens PLCs

To maximize the efficiency and ensure the safe operation of Siemens PLCs, proper handling and maintenance are crucial. These PLCs are designed with advanced technology and robust construction, requiring adherence to specific guidelines to prevent damage and ensure optimal performance. By following these best practices, users can extend the lifespan of their Siemens PLCs, making them a reliable solution for a wide range of industrial applications.

- Prevent Physical Damage: Handle with care to avoid physical damage to the PLC’s components, especially during installation and maintenance.

- Ensure Proper Ventilation: Install PLCs in well-ventilated areas to prevent overheating and maintain optimal operating temperatures.

- Protect from Electrical Surges: Use surge protectors and ensure proper grounding to safeguard PLCs from electrical surges that could damage the system.

- Moderate Environmental Conditions: Avoid exposing the PLC to extreme temperatures, humidity, or corrosive environments that could impair its performance.

- Stable Power Supply: Maintain a stable power supply to prevent fluctuations that could disrupt the PLC’s operation and cause unexpected shutdowns.

- Regular Firmware Updates: Keep the PLC’s firmware updated to ensure it is running the latest features and security patches.

- Routine Inspections: Conduct regular inspections and preventive maintenance to identify and address potential issues before they escalate.

At Uni Regal Corp., we prioritize the safety and reliability of our Siemens PLCs. If you have any questions or need assistance with your PLCs, our expert team is always ready to help.

Don’t hesitate to contact us for more information about our products and how we can support your automation needs.

Advantages of Siemens PLCs

Siemens PLCs stand out for their reliability, adaptability, and high performance in industrial automation, offering significant advantages over traditional control systems:

- Cost-Effectiveness: Siemens PLCs provide exceptional performance and durability, reducing the need for frequent replacements and minimizing long-term operational costs.

- Scalability: These PLCs are highly scalable, allowing you to expand your system as your automation needs grow, without requiring a complete overhaul.

- Energy Efficiency: Siemens PLCs are designed to optimize power consumption, contributing to more sustainable and cost-effective operations.

- High Performance: With fast processing speeds and large memory capacities, Siemens PLCs can handle complex automation tasks efficiently and reliably.

- Robust Connectivity: Siemens PLCs support a wide range of communication protocols, ensuring seamless integration with other systems and devices within your industrial setup.

These advantages highlight why Siemens PLCs are a preferred choice for businesses seeking reliable and efficient automation solutions across diverse industrial sectors.

Diverse Uses of Siemens PLCs

Siemens PLCs are renowned for their versatility and effectiveness across multiple industries. Their robust design and advanced capabilities make them indispensable in a wide range of automation applications. Here’s an exploration of their crucial functions:

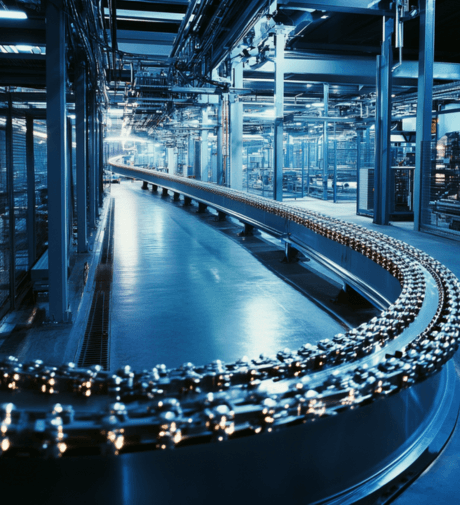

1. Smart Manufacturing

- Automated Assembly Lines: Siemens PLCs ensure precise control and synchronization of automated assembly lines, optimizing production efficiency.

- Robotics Integration: Manage and control robotic systems using Siemens PLCs to enhance accuracy, speed, and reliability in manufacturing processes.

- Real-Time Quality Control: Implement Siemens PLCs in quality control systems to monitor and adjust parameters in real-time, reducing defects and improving product consistency.

2. Chemical Processing

- Batch Processing: Siemens PLCs manage batch processing operations, ensuring accurate control over chemical reactions and mixtures.

- Safety Monitoring: Use Siemens PLCs to monitor safety systems, detecting and responding to hazardous conditions promptly.

- Environmental Compliance: Siemens PLCs help maintain compliance with environmental regulations by controlling emissions and waste processing systems.

3. Energy Management

- Power Distribution: Siemens PLCs manage the distribution of power across industrial facilities, optimizing energy use and reducing waste.

- Renewable Energy Control: Control renewable energy sources, such as wind and solar, ensuring efficient integration into the power grid.

- Energy Storage: Siemens PLCs manage energy storage systems, balancing supply and demand to maintain grid stability.

4. Oil and Gas Exploration

- Offshore Drilling: Siemens PLCs control offshore drilling operations, ensuring safety and efficiency in harsh environments.

- Pipeline Automation: Automate the monitoring and control of oil and gas pipelines with Siemens PLCs to prevent leaks and ensure safe transport.

- Refining Operations: Siemens PLCs optimize refining processes, controlling temperature, pressure, and chemical composition for high-quality outputs.

5. Pharmaceutical Manufacturing

- Precision Dosing: Siemens PLCs automate dosing processes in pharmaceutical production, ensuring accurate and consistent medication formulations.

- Regulatory Compliance: Monitor and document production processes with Siemens PLCs to meet stringent regulatory standards.

- Cleanroom Control: Siemens PLCs manage cleanroom environments, maintaining the necessary conditions for sterile pharmaceutical production.

6. Automotive Manufacturing

- Engine Assembly: Siemens PLCs control engine assembly processes, ensuring precision and consistency in high-volume production.

- Automated Painting: Manage automated painting processes with Siemens PLCs, achieving uniform finishes and reducing waste.

- Vehicle Testing: Siemens PLCs automate vehicle testing stations, ensuring each vehicle meets performance and safety standards before release.

7. Water and Wastewater Treatment

- Filtration Control: Siemens PLCs manage filtration systems, ensuring the efficient removal of contaminants from water supplies.

- Pump Station Automation: Automate pump stations with Siemens PLCs to ensure reliable water distribution and waste management.

- Chemical Dosing: Siemens PLCs control chemical dosing in water treatment processes, maintaining safe and effective water quality.

8. Food and Beverage Production

- Mixing and Blending: Siemens PLCs automate mixing and blending processes, ensuring consistency in flavor and texture across batches.

- Packaging Lines: Control packaging lines with Siemens PLCs, optimizing speed, accuracy, and product integrity.

- Temperature Regulation: Siemens PLCs manage temperature control in food production, ensuring products meet safety and quality standards.

9. Building Automation

- Smart HVAC Systems: Siemens PLCs control HVAC systems, optimizing energy efficiency and maintaining comfortable indoor environments.

- Lighting Automation: Automate building lighting systems with Siemens PLCs, enhancing energy savings and user comfort.

- Security Integration: Siemens PLCs integrate security systems, including access control, surveillance, and alarms, ensuring comprehensive building protection.

10. Transportation Systems

- Railway Signaling: Siemens PLCs manage railway signaling systems, ensuring safe and efficient train operations.

- Traffic Management: Automate traffic light systems with Siemens PLCs to improve traffic flow and reduce congestion.

- Airport Operations: Siemens PLCs control airport operations, including baggage handling, passenger flow, and security systems, ensuring smooth and secure travel experiences.

Siemens PLCs are essential for modern industrial and infrastructure applications, offering reliable, scalable, and efficient control solutions across diverse sectors. Their advanced capabilities make them the preferred choice for optimizing operations and enhancing productivity.

How to Choose the Right Siemens PLC Parts?

Selecting the appropriate Siemens PLC parts for your application is essential for ensuring smooth operation, scalability, and long-term success. Here’s a detailed guide to help you make the right choice:

1. Understand Your Operational Demands

- Application Scope: Define the scope of your automation tasks, such as process automation, discrete manufacturing, or hybrid processes.

- I/O Density: Assess the required input/output density, including both digital and analog, to match your system’s complexity and scale.

- Processing Requirements: Determine the need for processing speed and memory based on the complexity and real-time requirements of your application.

2. Assess Environmental and Operational Conditions

- Environmental Resilience: Consider the environmental factors, including temperature extremes, humidity, and potential exposure to corrosive substances.

- Operational Robustness: Ensure the PLC parts can endure operational stresses like mechanical vibration, electrical interference, and continuous operation.

3. Match the PLC Series to Your Needs

- SIMATIC S7-1200: Best for compact, cost-effective solutions where space and simplicity are critical.

- SIMATIC S7-1500: Ideal for high-performance applications requiring extensive processing power and advanced diagnostics.

- SIMATIC ET 200: Optimal for distributed I/O systems needing modularity and flexibility.

4. Evaluate Networking and Communication Requirements

- Protocol Integration: Confirm that the PLC supports essential communication protocols like Profinet, Profibus, or Modbus for seamless integration.

- Data Exchange: If your application demands extensive data exchange, ensure the PLC offers high-speed communication options and supports cloud connectivity for Industry 4.0 applications.

5. Consider Programming Flexibility and Integration

- Programming Standards: Check that the PLC supports standardized programming languages like IEC 61131-3 (Ladder Logic, Structured Text, etc.).

- System Integration: Ensure the PLC can integrate with existing automation systems, including legacy equipment, SCADA systems, and third-party devices.

6. Prioritize Safety and Compliance

- Safety Certifications: Ensure that the PLC components comply with international safety standards (e.g., SIL, PL) and are certified for use in your industry.

- Safety Features: Look for PLCs with integrated safety features, such as fail-safe I/Os, emergency shutdown capabilities, and real-time fault monitoring.

7. Analyze Total Cost of Ownership

- Initial Investment vs. Long-Term Savings: Consider not just the upfront cost, but also long-term savings through energy efficiency, reduced downtime, and ease of maintenance.

- Scalability and Future-Proofing: Choose a PLC that allows for future expansions and upgrades, minimizing future investments as your system grows.

8. Ensure Comprehensive Vendor Support

- Technical Support Availability: Confirm that the vendor offers extensive technical support, including 24/7 help desks, training programs, and detailed documentation.

- Warranty and Maintenance Services: Check the warranty terms and ensure that the vendor provides comprehensive maintenance services to support your investment over its lifecycle.

By thoroughly analyzing these aspects, you can select the Siemens PLC parts that perfectly align with your operational requirements, ensuring robust, scalable, and future-proof automation solutions.

6. Safety Integration

- Safety Modules: Integrate safety modules to enhance machine safety, including emergency stops, safety interlocks, and redundant control systems.

- Compliance Assurance: Ensure your automation systems meet necessary safety standards and certifications, such as CE, UL, and IEC.

7. User Interface Customization

- HMI Integration: Customize Human-Machine Interface (HMI) screens for intuitive control and monitoring of your processes.

- Access Control: Implement configurable security levels within your HMIs to restrict access based on user roles and responsibilities.

Siemens PLCs provide the adaptability and advanced features needed to tailor automation systems to your unique operational demands, ensuring efficiency, safety, and scalability.

Customizable Siemens PLC Solutions

Siemens PLCs (Programmable Logic Controllers) are known for their scalability and versatility, making them suitable for a wide range of industrial applications. Here’s how you can customize Siemens PLC solutions to fit your specific operational needs:

1. Modular Architecture

- Flexible Configuration: Customize your PLC system by adding or removing modules to fit your exact requirements.

- Expansion Capabilities: Easily expand your system by adding additional I/O modules, communication interfaces, and more.

2. Tailored Programming

- Custom Logic Development: Create tailored control logic to address specific process requirements and challenges.

- Application-Specific Functions: Develop custom functions within the PLC to handle unique operational processes efficiently.

3. Advanced Communication

- Network Integration: Integrate Siemens PLCs with existing networks using Profinet, Profibus, Modbus TCP, EtherNet/IP, and other protocols.

- Remote Monitoring and Control: Enable remote monitoring and control of your systems, improving operational flexibility and responsiveness.

4. Specialized Modules

- High-Speed Processing: Incorporate high-speed I/O modules and motion control units for applications requiring rapid data processing and control.

- I/O Diversity: Mix and match analog, digital, and specialized I/O modules to meet the precise needs of your application.

5. Environmental Adaptation

- Ruggedized Options: Choose ruggedized Siemens PLC models designed for operation in harsh industrial environments.

- Protective Coating: Utilize conformal coating options to protect PLC components from exposure to moisture, dust, and chemicals.

Why Choose Uni Regal Corp.?

skillful modern technique

At Uni Regal Corp., we utilize the most up-to-date methods and tools to ensure that our Siemens PLCs integrate seamlessly into your industrial systems, enhancing efficiency and performance.

Expert Professional Team

Our experienced team specializes in industrial automation and offers expert advice to help you select and implement the right Siemens PLC solutions for your specific needs.

High-Quality Components

We distribute only the highest quality Siemens PLC components, sourced directly from trusted manufacturers, ensuring reliability and durability in your operations.

24/7 support & guidence

We provide around-the-clock support and guidance, ensuring that any issues or questions are addressed promptly to keep your operations running smoothly.

In summery

Choosing the right Siemens PLC for your project can be daunting, especially if you’re navigating the complexities of industrial automation. But with the right partner by your side, the process becomes not only manageable but also a path to greater success.

At Uni Regal Corp., we pride ourselves on being more than just a distributor—we are your trusted partner in automation excellence. With years of industry expertise, we understand the critical role that reliable, high-quality PLCs play in your operations. That’s why we are committed to delivering Siemens PLCs that are not only tailored to your exact needs but also backed by our unwavering dedication to customer satisfaction.

When you choose Controllerpart.com, you’re choosing a team that’s deeply invested in your success. We provide personalized guidance, expert advice, and the assurance that you’re getting the best possible solutions for your automation challenges. With us, you’re not just buying components—you’re building a partnership that’s focused on driving your business forward with superior Siemens PLC solutions. Your success is our mission, and we are here to ensure that you have the optimal tools to achieve it.

Contact Uni Regal Corp. to Start Your Partnership

Stay informed with the latest updates from Uni Regal Corp., Bookmark our site, or connect with us on social media to keep up with industry trends and our newest offerings. For direct inquiries, simply fill out the contact form below. We’re here to discuss how we can support your business with top-quality Siemens PLCs and automation solutions. Let’s start building your success together!