Transform Your Automation with ABB PLCs

Leverage our customized ABB PLC solutions to redefine your automation systems. Built for exceptional performance, these PLCs offer unmatched reliability and precision, ensuring seamless operation even in the most challenging industrial environments. Now is the time to enhance your processes—upgrade to ABB PLCs and unlock new levels of efficiency and control. Contact us today to seamlessly integrate ABB PLCs into your automation strategy!

15

Years of experience

Your Premier Partner for ABB PLCs

“Empowering Automation with Elite Components and Custom-Built Solutions”

ABB PLCs are recognized for their exceptional control capabilities and steadfast reliability. Yet, the demands of modern industrial operations require solutions that transcend conventional setups. At CONTROLLERPART.COM, we excel in delivering ABB PLCs that are meticulously customized to address the unique complexities of your industrial processes, ensuring flawless integration and peak efficiency.

Our commitment to ABB PLCs is fueled by their versatility and precision, making them the perfect choice for a wide range of automation challenges. Whether you need processors, I/O modules, power supplies, or communication modules, our vast inventory caters to various industrial applications, providing superior operational performance.

Discover Uni Regal Corp’s advantage with our bespoke ABB PLC solutions, engineered to match your specific requirements in functionality, scalability, and system integration. Leverage our extensive industry knowledge to secure automation solutions that surpass your expectations. Contact us today to elevate your automation systems with our specialized, high-performance ABB PLCs.

- Custom-Built Solutions: We deliver ABB PLCs that are expertly tailored to the distinct needs of your industrial operations, regardless of project scale.

- Unmatched Expertise: Our team’s deep knowledge of industrial automation guarantees top-tier advice and support.

- Cost-Effective Pricing: We offer premium automation products with pricing structured to provide the best return on your investment.

- Comprehensive Selection: Our wide array of ABB components ensures we can fulfill your diverse automation requirements with speed and efficiency.

- Reliable Shipping: Our streamlined logistics ensure that your orders are delivered promptly and reliably.

- Unwavering Quality: We are committed to excellence in both our products and customer service, ensuring a smooth and dependable partnership.

Your Premier Provider for ABB PLCs

Crafted for maximum efficiency and robust performance, our ABB PLCs are designed to excel in the most rigorous industrial settings. Built to withstand extreme conditions, these PLCs ensure your operations are seamless and uninterrupted. Trust us to deliver top-tier automation solutions that empower your business to achieve new levels of productivity and reliability.

Customize Your ABB PLC Solutions with Uni Regal Corp.

Experience a seamless customization journey with Uni Regal Corp. Our efficient four-step process ensures you receive expert guidance every step of the way, tackling potential challenges with ease:

Step 1.

Assessing Your Operations

Share key details about your operation, including unique system requirements, environmental conditions, load demands, overall system voltage, and crucial performance metrics.

Step 2.

Defining Your Automation Goals

Outline the specific automation processes you aim to enhance—whether in production control, process automation, robotics, machine safety, or any other specialized area.

Step 3.

Selecting ABB PLC Components

Choose the precise components your system requires, from PLCs and I/O modules to power supplies, communication interfaces, and other ABB equipment tailored to your needs.

Step 4

Refining Your Specifications

Finalize your detailed requirements and QTYs, ensuring each selected component aligns perfectly with your operational objectives, delivering a solution customized for peak performance.

Consult with our Engineers

Frequently asked questions

Common Inquiries about ABB PLCs

To make your experience smoother, we’ve gathered responses to the most commonly asked questions regarding our ABB PLCs. If you have further questions or need more information, please feel free to reach out to us directly.

ABB PLCs are programmable logic controllers that automate and streamline industrial processes by controlling machinery and systems. They enhance efficiency, accuracy, and safety across various industrial applications.

ABB PLCs are trusted in industries like manufacturing, automotive, oil and gas, food and beverage, and utilities, valued for their reliability, adaptability, and robust performance.

We offer a wide selection of ABB PLCs, including the AC500, AC500-eCo, AC500-S, AC500-XC, and AC31 series, each with multiple configurations to suit diverse industrial needs.

Absolutely. Our ABB PLCs can be tailored to your project’s unique requirements, ensuring seamless integration and optimal performance for your application.

Delivery times depend on the complexity of the customization, but we prioritize swift production and timely delivery to align with your project schedules.

Pricing varies based on the model, configuration, and customization level. We offer competitive pricing designed to fit your specific automation needs.

The lifespan of ABB PLCs depends on the application and environmental conditions. With proper maintenance, they are known for their durability and long-lasting performance.

Choosing the right PLC series affects processing speed, memory capacity, and I/O compatibility. We can guide you in selecting the optimal series for your operational demands.

We back our products’ quality with warranties tailored to meet your needs, ensuring confidence in the performance and durability of our ABB PLCs.

ABB PLCs are compatible with a wide range of communication protocols, including PROFINET, Modbus, and Ethernet/IP, offering flexibility for various industrial networking requirements.

Yes, we provide comprehensive support for the installation, programming, and ongoing maintenance of ABB PLCs to ensure smooth and efficient operations.

Regular inspections, firmware updates, and cleaning are essential to maintaining the performance and longevity of your ABB PLCs. We can provide detailed maintenance guidelines to help you maximize your system’s lifespan.

Your Ultimate Guide to Acquiring ABB PLCs

Explore the transformative role ABB PLCs play in elevating industrial automation, from optimizing production lines to managing intricate control systems. Learn how these PLCs not only boost operational efficiency and reliability but also provide exceptional scalability, making them suitable for a wide array of industrial environments.

This guide dives deep into the adaptability of ABB PLCs across industries such as robotics, process automation, and machine safety, highlighting their critical function in maintaining smooth and reliable operations. Whether you’re embarking on a new automation project or planning extensive acquisitions, our guide offers essential insights to help you select the perfect ABB PLCs, designed to meet your exact operational needs. Furthermore, discover the long-term advantages of investing in ABB’s cutting-edge technology, ensuring your systems are not only resilient and adaptable but also equipped to thrive in a rapidly changing industrial landscape.

Table of Contents

Exploring the Capabilities of ABB PLCs

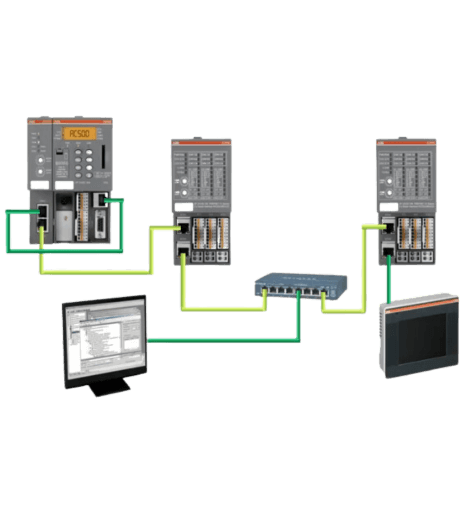

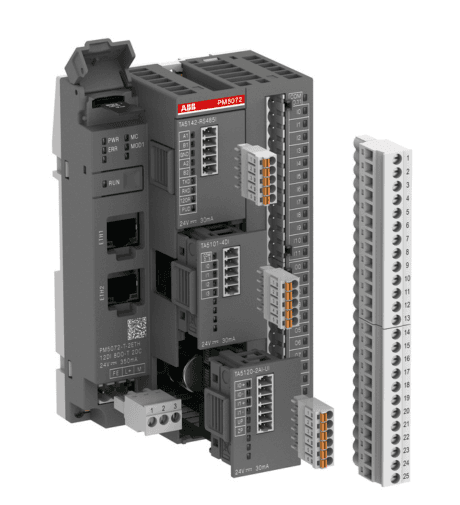

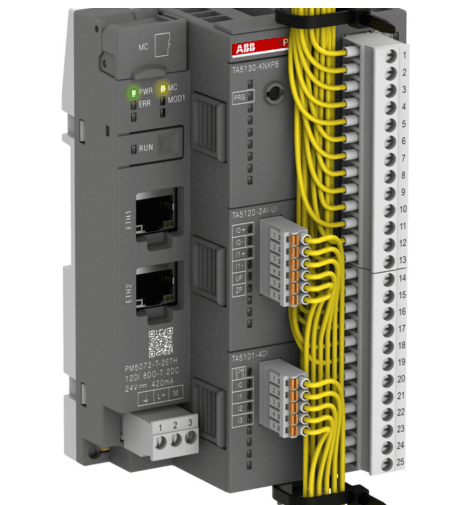

ABB PLCs (Programmable Logic Controllers) are advanced industrial control systems designed to automate and optimize complex operations across a wide range of industries. These controllers boast a modular architecture, providing unmatched flexibility and scalability to meet the specific demands of various industrial environments.

Recognized for their durability, precision, and outstanding performance, ABB PLCs are the go-to solution for applications such as process control, machinery automation, and cutting-edge robotics. Their ability to handle intricate tasks with exceptional accuracy and consistent reliability makes them indispensable in industries where efficiency and precise control are paramount.

ABB PLCs are equipped with state-of-the-art features, including robust communication protocols, versatile I/O configurations, and powerful processing capabilities. This ensures smooth integration and peak performance within any automation framework. For businesses aiming to enhance their production processes and achieve the highest levels of automation, ABB PLCs represent a vital investment in long-term growth and technological advancement.

Essential Specifications of ABB PLCs

ABB PLCs are engineered to meet the rigorous demands of industrial automation, offering robust specifications and innovative features. Here are some key specifications:

CPU Modules

- Processing Speed: Ultra-fast processing, with execution times as low as 1 ns per instruction.

- Memory: Scalable memory options ranging from 64 KB to 2 MB, suitable for a variety of applications.

- I/O Capacity: Supports from 64 to 65,536 I/O points, ensuring flexibility for even the most complex systems.

- Communication Interfaces: Equipped with EtherNet/IP, Modbus, RS-232, and more for seamless connectivity.

- Programming Flexibility: Supports multiple programming languages including Ladder Logic, Structured Text, Function Block Diagram, and Sequential Function Chart.

Power Supply

- Input Voltage Options: Available in 24 VDC, 48 VDC, and 120-230 VAC, providing compatibility with a wide range of systems.

- Energy Efficiency: Designed for low power consumption, ranging from 10W to 100W, ensuring cost-effective operation.

I/O Modules

- Digital Inputs: Available in configurations such as 24VDC, 110VAC, and 230VAC for broad application use.

- Digital Outputs: Offers Relay, Transistor, and Triac output options to meet diverse system requirements.

- Analog Inputs: Precision control with support for ±10V voltage and 0-20mA current inputs.

- Analog Outputs: Provides accurate output control with ±10V voltage and 0-20mA current capabilities.

- Specialty Modules: Includes advanced modules like high-speed counters, PID controllers, motion control, and safety modules to enhance functionality.

Communication

- Supported Protocols: Compatibility with a wide range of protocols including EtherNet/IP, Modbus TCP, PROFINET, and DeviceNet, ensuring versatile integration.

- Network Topologies: Supports various network configurations such as Star, Line, Ring, and Mesh to fit your specific architecture needs.

Environmental Specifications

- Operating Temperature Range: Reliable performance across extreme temperatures from -25°C to 70°C.

- Storage Temperature: Capable of withstanding storage conditions from -40°C to 85°C.

- Humidity Tolerance: Functions effectively in environments with 5% to 95% relative humidity (non-condensing).

- Vibration Resistance: Built to endure vibrations with 5 Hz to 8 Hz at 3.5 mm amplitude and 8 Hz to 200 Hz at 9.8 m/s² acceleration.

Certifications and Compliance

- Certifications: Fully compliant with CE, UL, CSA, and ATEX certifications, ensuring safety and quality.

- Industry Standards: Adheres to key industry standards including IEC 61131-2, IEC 61508, IEC 62061, and ISO 13849, guaranteeing reliability and performance.

With these specifications, ABB PLCs deliver exceptional reliability, performance, and versatility, making them the ideal choice for businesses seeking to optimize and future-proof their automation systems.

Best Practices for Safely Using ABB PLCs

To maximize the lifespan and ensure the safe operation of ABB PLCs, it’s crucial to adhere to best practices in handling, installation, and maintenance. These PLCs are designed with state-of-the-art technology and robust construction, making it essential to follow safety protocols to avoid damage and maintain optimal performance. By implementing these guidelines, users can ensure that their ABB PLCs continue to deliver reliable and efficient performance across a wide range of industrial applications.

- Prevent Physical Damage: Handle ABB PLCs carefully during installation and maintenance to avoid any physical impact that could compromise the integrity of the components and affect functionality.

- Provide Sufficient Ventilation: Install PLCs in well-ventilated areas to prevent overheating and ensure that the equipment operates within its recommended temperature range.

- Safeguard Against Electrical Surges: Utilize surge protection devices and ensure proper grounding to protect PLCs from voltage spikes that could cause serious damage.

- Control Environmental Factors: Place PLCs in environments with controlled temperatures and humidity levels, and away from corrosive substances, to prevent degradation and maintain peak performance.

- Ensure Power Stability: Maintain a consistent and stable power supply to avoid voltage fluctuations that could disrupt PLC operations or cause unexpected system failures.

- Keep Firmware Up to Date: Regularly update the PLC’s firmware to access the latest improvements in functionality and security, ensuring the system remains current and protected.

- Conduct Regular Maintenance Checks: Perform routine inspections and preventive maintenance to detect and resolve potential issues before they lead to downtime or reduced performance.

At Uni Regal Corp., we are committed to the safety, reliability, and optimal performance of our ABB PLCs. Our team of experts is available to assist you with any questions or support you may need.

Contact us today to learn more about our products and how we can help you achieve your automation goals.

Advantages of Selecting ABB PLCs

ABB PLCs are highly regarded for their dependability, adaptability, and top-tier performance in industrial automation. They offer a host of advantages over traditional control systems:

- Cost-Effectiveness: ABB PLCs are built to last, minimizing the frequency of replacements and significantly reducing long-term operational costs, making them a smart investment.

- Scalability: Designed with growth in mind, ABB PLCs allow you to expand your automation systems easily as your business evolves, without requiring a complete system redesign.

- Energy Efficiency: ABB PLCs are optimized for energy conservation, helping to lower power consumption and contributing to more sustainable and economical operations.

- High Performance: With fast processing speeds and extensive memory, ABB PLCs handle complex automation processes with ease, delivering consistent and reliable performance.

- Advanced Connectivity: ABB PLCs support a wide range of communication protocols, ensuring smooth integration with other systems and devices in your industrial setup.

These advantages make ABB PLCs the go-to solution for businesses that demand reliable, efficient, and scalable automation systems across various industries.

Harnessing the Power of ABB PLCs Across Industries

ABB Programmable Logic Controllers (PLCs) are at the heart of modern industrial automation, offering unparalleled flexibility and resilience that cater to a vast array of sectors. Their robust design and innovative technology make them indispensable for businesses aiming to elevate their operational efficiency and maintain a competitive edge. Here’s an exploration of the myriad ways ABB PLCs revolutionize various industries:

Next-Generation Manufacturing

- Seamless Production Workflows: ABB PLCs orchestrate intricate production lines, ensuring synchronization and maximizing throughput while minimizing downtime.

- Robotic Synergy: Integrating effortlessly with advanced robotic systems, these PLCs enhance precision, speed, and reliability in manufacturing processes.

- Adaptive Quality Control: Real-time monitoring allows for immediate adjustments, ensuring consistent product quality and reducing waste.

Pioneering Chemical Processing

- Exacting Batch Management: ABB PLCs provide meticulous control over chemical reactions, ensuring consistency and safety in batch processing.

- Proactive Safety Measures: Continuous monitoring of critical parameters enables swift responses to potential hazards, safeguarding both personnel and equipment.

- Environmental Stewardship: Efficient management of emissions and waste aligns with stringent environmental standards, promoting sustainable operations.

Transformative Energy Solutions

- Optimized Power Distribution: Efficient management of energy flow reduces wastage and ensures reliable power across facilities.

- Renewable Integration: Seamlessly incorporating renewable sources like solar and wind, ABB PLCs support a sustainable and balanced energy mix.

- Dynamic Storage Management: Balancing supply and demand, these PLCs oversee energy storage systems to maintain grid stability.

Strategic Oil and Gas Operations

- Offshore Excellence: In challenging environments, ABB PLCs ensure that offshore drilling operations are conducted safely and efficiently.

- Pipeline Integrity: Automated monitoring prevents leaks and ensures the secure transportation of resources through extensive pipeline networks.

- Refinery Optimization: Fine-tuned control over variables like temperature and pressure enhances refining processes, maximizing output quality.

Cutting-Edge Pharmaceutical Production

- Precision Dosing: ABB PLCs facilitate exact ingredient measurements, ensuring each pharmaceutical product meets rigorous quality standards.

- Regulatory Compliance: Comprehensive tracking and documentation capabilities assist in adhering to strict industry regulations.

- Sterile Environment Maintenance: Ensuring contamination-free production spaces is vital, and ABB PLCs play a crucial role in upholding these standards.

Innovative Automotive Manufacturing

- Engine Assembly Precision: From individual components to complete vehicles, ABB PLCs guarantee meticulous assembly, fostering consistency and reliability.

- Automated Finishing Processes: Managing sophisticated painting and finishing systems, these controllers ensure flawless results, reducing rework.

- Comprehensive Testing Automation: Ensuring every vehicle meets performance and safety benchmarks before reaching consumers.

Efficient Water Management

- Advanced Filtration Control: ABB PLCs optimize water purification processes, delivering safe and clean water to communities and industries.

- Pumping Station Automation: Reliable operation of pump stations ensures consistent water supply and effective wastewater treatment.

- Chemical Treatment Regulation: Precise control over chemical dosing maintains water quality and complies with environmental standards.

Dynamic Food and Beverage Processing

- Consistent Product Quality: Automating mixing and blending ensures uniform taste and texture across all batches.

- Streamlined Packaging: Enhancing speed and accuracy in packaging preserves product integrity and extends shelf life.

- Temperature Regulation: Maintaining optimal processing temperatures is critical for safety and quality, expertly managed by ABB PLCs.

Intelligent Building Automation

- Energy-Efficient Climate Control: ABB PLCs optimize HVAC systems, balancing occupant comfort with energy conservation.

- Adaptive Lighting Solutions: Automating lighting based on occupancy and natural light contributes to significant energy savings.

- Integrated Security Systems: Coordinating surveillance, access control, and alarms provides comprehensive building security.

Enhanced Transportation Infrastructure

- Reliable Railway Operations: Managing signaling and controls, ABB PLCs ensure safe and timely train services.

- Optimized Traffic Management: Automated systems improve traffic flow, reducing congestion and environmental impact.

- Streamlined Airport Functions: From baggage handling to passenger movement, these controllers enhance the efficiency and safety of air travel.

ABB PLCs are more than just components in a system; they are the backbone of innovation and efficiency across industries. Their adaptability, coupled with advanced features, positions them as the ideal choice for businesses striving to future-proof their operations and achieve unparalleled excellence in automation.

How to Choose the Perfect ABB PLC Components

Selecting the right ABB PLC components is vital for achieving optimal performance, scalability, and long-term dependability. Here’s a detailed guide to help you make the best choice:

1. Define Your Operational Objectives

- Scope of Application: Clearly outline the goals of your automation tasks, whether it’s for process automation, discrete manufacturing, or a hybrid approach.

- I/O Capacity: Determine the required input/output capabilities, considering both digital and analog needs to match the complexity and scale of your system.

- Processing Capabilities: Evaluate the necessary processing speed and memory to meet the demands of your application, especially if it involves real-time operations.

2. Factor in Environmental and Operational Conditions

- Environmental Resilience: Consider the environmental conditions your PLCs will face, such as temperature fluctuations, humidity, and exposure to corrosive elements.

- Operational Durability: Ensure the components can endure operational challenges like mechanical vibrations, electrical interference, and prolonged usage.

3. Select the Right PLC Series for Your Needs

- AC500-eCo Series: Ideal for cost-effective, compact solutions where space and budget are key considerations.

- AC500 Series: Perfect for mid-range applications requiring strong processing power and advanced diagnostics.

- AC500-XC Series: Best for high-performance and extreme conditions, offering extensive processing capabilities and modular flexibility.

4. Address Networking and Communication Requirements

- Protocol Compatibility: Make sure the PLC supports essential communication protocols like EtherNet/IP, PROFINET, or Modbus, ensuring smooth integration into your system.

- Data Management: For applications with extensive data needs, opt for PLCs that offer high-speed communication and cloud connectivity, essential for Industry 4.0 advancements.

5. Ensure Programming Flexibility and Integration Ease

- Programming Standards: Confirm that the PLC supports recognized programming languages, such as those under IEC 61131-3 (e.g., Ladder Logic, Structured Text).

- System Integration: Ensure the PLC can easily integrate with your existing automation infrastructure, including legacy equipment, SCADA systems, and third-party devices.

6. Prioritize Safety and Compliance

- Safety Standards: Ensure that the PLC components comply with international safety standards (such as SIL and PL) and are certified for your specific industry.

- Integrated Safety Features: Look for PLCs with built-in safety functionalities like fail-safe I/Os, emergency shutdown capabilities, and real-time fault detection.

7. Consider Total Cost of Ownership

- Upfront vs. Long-Term Costs: Assess the long-term benefits, including energy efficiency, reduced downtime, and ease of maintenance, rather than focusing solely on the initial price.

- Scalability and Future-Proofing: Choose a PLC that allows for easy expansion and upgrades, helping you save on future costs as your system grows.

8. Ensure Comprehensive Vendor Support

- Technical Assistance: Verify that the vendor provides strong technical support, including 24/7 assistance, training, and detailed product documentation.

- Warranty and Maintenance Services: Review the warranty coverage and confirm that the vendor offers extensive maintenance services to safeguard your investment over time.

By thoroughly evaluating these factors, you can choose the ABB PLC components that best align with your operational requirements, ensuring a reliable, scalable, and future-ready automation system.

6. ADVANCED SAFETY FEATURES

Comprehensive Safety Integration: Elevate the safety of your machinery by integrating cutting-edge safety modules such as emergency shutdown systems, safety interlocks, and redundant control circuits. These enhancements help prevent accidents and ensure smooth operation even under critical conditions.

Compliance Assurance: Ensure that your automation system complies with essential safety standards and certifications like CE, UL, and IEC, giving you confidence that your operations are secure and meet industry regulations.

7. CUSTOMIZED USER INTERFACES

Tailored HMI Solutions: Develop and deploy custom Human-Machine Interface (HMI) screens that offer user-friendly controls and provide real-time insights into your operations. These interfaces can be designed to meet the specific needs of your workflow, enhancing both usability and efficiency.

Enhanced Access Control: Implement customizable security protocols within your HMIs, allowing you to control access to critical system functions based on user roles and permissions, thereby protecting sensitive operations.

ABB PLCs are renowned for their versatility and advanced capabilities, making them ideal for tailoring your automation systems to meet precise operational demands. These features ensure that your systems not only operate efficiently but also maintain the highest standards of safety and scalability.

TAILORED ABB PLC SOLUTIONS

ABB PLCs (Programmable Logic Controllers) are renowned for their flexibility and ability to adapt to a wide range of industrial environments. Here’s how you can customize ABB PLC solutions to perfectly align with your unique operational needs:

1. MODULAR SYSTEM DESIGN

Adaptable Configuration: Build your PLC system with a modular structure that allows you to easily add or remove components, ensuring your setup is precisely tailored to your specific application requirements.

Scalable Growth: Seamlessly expand your system by incorporating additional I/O modules, communication interfaces, and other components as your operational needs evolve.

2. CUSTOM PROGRAMMING CAPABILITIES

Tailored Logic Development: Create custom control logic that addresses the distinct challenges and processes of your operations, optimizing performance and efficiency.

Industry-Specific Applications: Implement specialized functions within the PLC to streamline workflows, enhance productivity, and meet the unique demands of your industry.

3. ADVANCED COMMUNICATION OPTIONS

Effortless Network Integration: Connect ABB PLCs to your existing networks using a variety of industry-standard protocols such as EtherNet/IP, PROFINET, Modbus TCP, and more, ensuring seamless integration and communication across your systems.

Remote Monitoring and Control: Enable remote access to monitor and control your operations from anywhere, providing greater flexibility and quicker response times in managing your automation systems.

4. SPECIALIZED MODULE INTEGRATION

High-Speed Processing: Integrate high-performance I/O modules and motion control units for applications requiring rapid data processing and precise control, ensuring that your systems operate at peak efficiency.

Custom I/O Configurations: Mix and match analog, digital, and specialty I/O modules to design a system that meets the exact needs of your specific application, maximizing operational effectiveness.

5. ENVIRONMENTAL CUSTOMIZATION

Rugged Design Options: Choose robust ABB PLC models that are engineered to withstand extreme industrial conditions, including wide temperature ranges, high humidity, and harsh environments.

Environmental Protection: Opt for protective enhancements like specialized coatings and sealed enclosures to safeguard your PLC components against environmental hazards such as moisture, dust, and corrosive chemicals, ensuring long-lasting durability.

How to Select a Trusted Supplier for ABB PLCs?

Choosing the right supplier for your ABB PLC needs is crucial to ensuring the success and longevity of your automation projects. Here’s a concise guide to help you make a well-informed decision:

Selecting a supplier with extensive industry experience is crucial. Ensure they offer a broad range of ABB PLCs, such as the AC500 series, and provide customization options to meet your specific project needs. Expertise in tailoring solutions guarantees that the PLCs will seamlessly integrate with your existing systems.

Prioritize suppliers that adhere to international quality standards and certifications. It’s vital that ABB PLCs undergo rigorous testing and quality control to ensure durability and reliable performance. Suppliers should also have in-depth knowledge of material compatibility to recommend the best components for your operations.

A reliable supplier should offer comprehensive technical support throughout your project. This includes guidance on PLC selection and system optimization. Additionally, research customer reviews and references to gauge the supplier’s reputation and commitment to customer satisfaction.

Ensure the supplier is known for timely delivery of ABB PLCs, which is crucial for maintaining your project timeline. After-sales support, including warranties and maintenance services, should also be a key consideration to safeguard your investment and ensure long-term system performance.

In Conclusion

ABB PLCs are renowned for their adaptability and powerful performance, making them indispensable across industries, from manufacturing to energy management.

At Uni Regal Corp., we offer an extensive range of both standard and customized ABB PLC solutions designed to meet diverse industrial needs. With our deep expertise in distributing ABB products, we deliver globally recognized components, configurations, and solutions that are precisely tailored to your projects. Our experienced team is dedicated to helping you select the ideal PLC to match your specific operational demands, ensuring the success and efficiency of your automation initiatives.

Streamline Your ABB PLC Requirements

Meet your ABB PLC needs effortlessly with our specialized solutions. With extensive expertise in the field, we design and deliver tailored PLC systems that perfectly align with your operational demands. By sourcing and managing our components in-house, we maintain superior quality control and offer pricing that outshines global competitors.

Don’t settle for less when it comes to your automation systems. Partner with us today to experience efficient, high-quality ABB PLC solutions that give you a competitive edge.