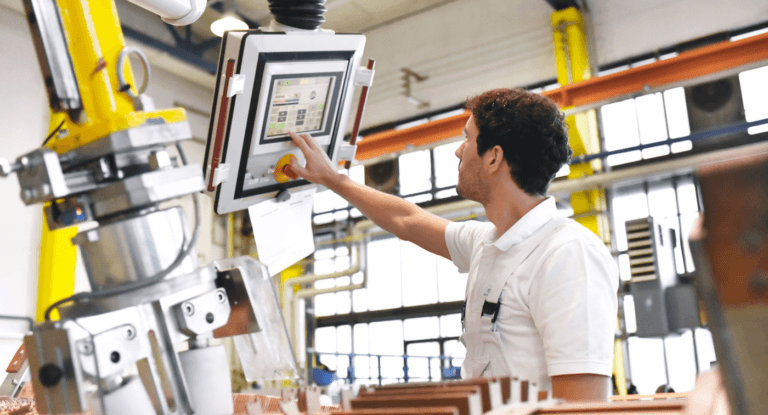

Take Control with Robust Industrial HMIs

Maximize your factory’s efficiency with Uni Regal Corp.’s durable and high-performance HMIs. Crafted to excel in harsh industrial settings, our HMIs provide reliable operation and precise control. We understand your concerns about maintaining productivity and minimizing downtime – that’s why our HMIs are engineered for seamless integration, simplifying complex workflows, and ensuring your systems run smoothly. Trust Uni Regal to deliver the reliability and durability your operations demand, making us the go-to choice for professionals who won’t compromise on efficiency.

15

Years of experience

Your Trusted Partner for Sourcing Reliable HMIs

“Streamline Your HMI Procurement with Expert Support and Quality You Can Trust”

When sourcing HMIs, you need more than just a supplier—you need a partner who understands the complexities of industrial automation and can deliver the right solutions without the hassle. At CONTROLLERPART.COM, we distribute high-quality HMIs from leading brands like Mitsubishi, Omron, and Siemens, ensuring you get the performance and reliability your operations demand.

We know the challenges you face—whether it’s finding the right HMI for your specific application, ensuring compatibility with existing systems, or managing tight timelines. That’s why our team is dedicated to making your procurement process as smooth as possible. We offer expert guidance to help you select the best HMIs for your needs, and our strong relationships with top manufacturers ensure that you receive authentic, top-tier products every time.

Our commitment goes beyond just providing the products. We understand that timely delivery, product availability, and post-purchase support are critical to your business. That’s why we offer streamlined logistics, flexible options, and responsive customer service to address your concerns and keep your operations running smoothly. With CONTROLLERPART.COM, you’re not just getting an HMI—you’re getting a reliable partner invested in your success.

- Expert Selection: Leverage our deep industry knowledge to choose the right HMIs from top brands, tailored to your specific requirements.

- Guaranteed Authenticity: We source directly from trusted manufacturers, ensuring you receive genuine, high-quality HMIs.

- Efficient Procurement: Enjoy a hassle-free buying process with our streamlined logistics and flexible delivery options.

- Responsive Support: Our team is here to assist you at every stage, from product selection to after-sales service, ensuring a smooth experience.

- Wide Range of Options: Access a comprehensive inventory of HMIs, giving you the flexibility to find the perfect match for your application.

- Timely Delivery: We prioritize prompt shipping, so your HMIs arrive on schedule, minimizing downtime and keeping your projects on track.

Your Top Choice for Industrial HMIs

As a trusted distributor of leading brands like Mitsubishi, Omron, and Siemens, we provide durable, high-performance HMIs designed for demanding industrial environments. Rely on us for reliable, top-quality interfaces that ensure seamless operations and boost productivity.

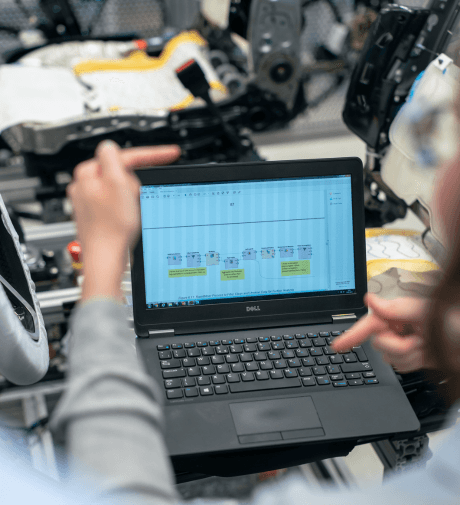

Design Your Perfect HMI Solutions with Uni Regal Corp.

At Uni Regal Corp., we make it easy to tailor your HMI solutions to your exact needs. With our straightforward, four-step process, you remain in control while we provide the expertise to bring your vision to life.

Step 1.

Pinpoint Your Needs

Start by identifying your unique operational demands—whether it’s the harsh environment, integration with existing systems, or specific performance benchmarks, we’re here to listen.

Step 2.

Define your Vision

What’s your end goal? Whether it’s optimizing production workflows, enhancing machine interfaces, or boosting overall system efficiency, outline your vision, and we’ll help you achieve it.

Step 3.

Select Your HMI Components

Dive into our extensive range of HMIs from industry leaders like Mitsubishi, Siemens, and Omron. Choose the exact models that align with your needs and operational goals.

Step 4

Finalize and being Perfect

Lock in the specifics—confirm the details and quantities of your selected HMIs, ensuring every component fits seamlessly into your system, ready to deliver top-notch performance from day one.

Consult with our Engineers

Frequently asked questions

Common Questions about Industrial HMIs

To help you navigate the HMI procurement process with confidence, we’ve answered some of the most common questions our clients have. Our goal is to ensure you have all the information you need to make the right choice for your operations. If you have additional questions, don’t hesitate to reach out to us directly.

Choosing the right HMI involves understanding your specific operational environment, the complexity of your control tasks, and your system integration needs. We’re here to help you pinpoint the exact features and models that will best serve your application

We distribute top-quality HMIs from trusted brands like Mitsubishi, Siemens, Omron, and more. Each brand offers unique strengths, from user-friendly interfaces to robust performance in harsh conditions. We can guide you in selecting the brand that aligns with your needs.

Our team will work closely with you to ensure compatibility with your current setup, addressing any concerns about integration. We provide detailed guidance on the best practices to seamlessly incorporate your new HMI into your existing network.

We offer comprehensive support, including installation assistance and setup guidance. Our experts are on hand to help you get your HMI up and running smoothly, ensuring it performs as expected from day one.

We understand that timing is critical. Our streamlined logistics ensure that we deliver your HMIs promptly, minimizing any disruption to your operations. We’ll keep you informed every step of the way.

While costs vary depending on the brand and model, we pride ourselves on offering competitive pricing. We work to find the best solutions that fit your budget without compromising on quality.

Absolutely, operators can manually override automatic control operations using Human-Machine Interfaces (HMIs). These interfaces are designed to provide operators with the flexibility to intervene in automated processes whenever necessary.

Key Benefits of Manual Override via HMI:

- Handling Unexpected Behaviors: In situations where the system behaves unpredictably, operators can take control to ensure safety and maintain operations.

- Facilitating Maintenance: During maintenance tasks, manual control allows operators to adjust or stop processes without disrupting the entire system.

By allowing manual overrides, HMIs introduce an essential layer of flexibility and redundancy to various control systems, ensuring that operators always have the option to respond dynamically to changing conditions.

Absolutely. We’re committed to supporting you beyond the purchase. Whether you need troubleshooting assistance or routine maintenance tips, our team is here to ensure your HMI continues to operate at peak performance.

We offer warranties that reflect the high standards of the HMIs we distribute. These warranties provide peace of mind, knowing that your investment is protected against potential issues.

Yes, we specialize in finding the right HMI solutions for unique challenges. Whether you’re dealing with extreme temperatures, high humidity, or specific safety requirements, we’ll help you select an HMI that meets your specific conditions.

The HMIs we distribute are built to last, even in tough industrial environments. With proper maintenance, these devices will provide reliable performance for years. We can advise on the best models for durability and long-term use.

Absolutely. We provide comprehensive support for the installation, programming, and integration of your HMIs, ensuring they function seamlessly within your system and meet your operational needs.

Regularly clean the touch screen, keep the HMI software updated, and ensure proper ventilation to prevent overheating. We also recommend periodic checks of all connections and backups of your configuration settings to keep your HMIs performing optimally.

When designing Human-Machine Interfaces (HMI), it’s crucial to extend the focus beyond mere technical functionality to embrace usability and human factors. These elements are essential because they directly affect how users experience and interact with the system.

Why Usability Matters

Usability involves crafting interfaces that harmonize with human perception, cognition, and interaction. Here’s why that matters in HMI design:

Ease of Understanding: A well-designed HMI interface enables users to quickly understand the current system status. This is achieved through intuitive graphics, symbols, and layouts that communicate information effectively.

Rapid Learning Curve: Interfaces must be intuitive, ensuring that users can quickly learn to interpret data and perform tasks with minimal training. Consistency in design plays a pivotal role here, making navigation second nature.

Operational Efficiency: By integrating ergonomic principles, interfaces become tailored for streamlined workflows. Elements such as controls and navigation must be designed for ease, reducing user fatigue and increasing efficiency.

The Impact of Human Factors

Human factors delve into how people interact with systems. Implementing a strong human factors approach in HMI design prevents common pitfalls that can reduce effectiveness and introduce risks:

Error Reduction: By accommodating human strengths and limitations, designs can minimize user errors, enhancing both safety and performance.

User Satisfaction: Systems that align with natural human patterns tend to be more satisfying to use, boosting morale and productivity.

Enhanced Safety: Properly considering human factors can mitigate risks by ensuring operators have clear, accessible, and actionable information during both routine and critical operations.

Integrating usability and human factors into HMI design isn’t just beneficial—it’s essential. These considerations improve the overall user experience and performance of the interface, helping to ensure safety and effectiveness in any operational environment.

Your Comprehensive Guide to Choosing Industrial HMIs

Explore how Industrial HMIs can transform your automation systems, from simplifying control processes to enhancing real-time monitoring. This guide highlights the critical role HMIs play in boosting operational efficiency and reliability, offering intuitive interfaces and robust performance suitable for a wide range of industrial environments.

Discover the versatility of HMIs across various applications, including process automation, machinery control, and safety monitoring. We delve into how these interfaces support smooth and dependable operations, whether you’re implementing new systems or upgrading existing ones. Our guide provides essential insights to help you choose the right HMI, tailored to your specific operational requirements.

Additionally, learn about the long-term benefits of investing in cutting-edge HMI technology, ensuring your systems remain resilient, adaptable, and equipped to meet the demands of an ever-evolving industrial landscape.

Table of Contents

What Are Industrial HMIs?

Industrial Human-Machine Interfaces (HMIs) are advanced systems that serve as the critical interaction point between operators and industrial equipment. These interfaces enable users to control machines, monitor processes, and visualize data in real time, making them indispensable in the automation landscape. By translating complex machine data into intuitive, accessible formats, HMIs allow operators to make informed decisions quickly and efficiently.

A key component of these HMIs is the Graphical User Interface (GUI). The GUI provides a visually intuitive way for operators to engage with machines within industrial control systems. It leverages symbols, colors, and touchscreen capabilities to facilitate operations and reduce human error. This visual approach simplifies complex data, ensuring that operators can interact with machines seamlessly and effectively.

Incorporating GUIs into HMIs enhances the overall user experience by:

- Improving Interaction: GUIs transform abstract machine data into easy-to-understand visual elements, allowing operators to quickly grasp system status and performance.

- Enhancing Efficiency: The intuitive nature of GUIs reduces the learning curve and operational errors, leading to smoother and more efficient processes.

- Boosting Safety: By minimizing human error, GUIs contribute to safer industrial environments.

Together, these elements ensure that industrial HMIs are not just tools but essential components that drive automation forward, making complex machinery accessible to those who operate them.

Designed to meet the rigorous demands of industrial environments, HMIs come equipped with robust features like touchscreens, programmable displays, and multi-language support, ensuring they can be used effectively across various settings. Whether it’s a simple display panel for basic operations or a complex interface for controlling an entire production line, industrial HMIs are engineered to enhance both functionality and user experience.

At the core of their design, HMIs are built to integrate seamlessly with other industrial automation components, including Programmable Logic Controllers (PLCs), sensors, and supervisory systems. This integration ensures that operators can manage operations from a single interface, streamlining workflows and reducing the likelihood of errors.

In essence, industrial HMIs are the nerve centers of modern factories, providing the tools necessary for precision control, real-time monitoring, and data-driven decision-making. For industries focused on improving efficiency, reducing downtime, and maintaining high safety standards, HMIs are not just an option—they are essential.

Essential Features of Industrial HMIs

Industrial HMIs are at the forefront of automation technology, designed to empower operators and streamline operations with advanced capabilities. Here’s a closer look at what makes these systems indispensable:

Interactive Displays

- Versatile Screen Sizes: From compact 4.3″ screens to expansive 15″ displays, choose the perfect size to fit your operational space and needs.

- Crystal-Clear Resolution: High-definition visuals ensure every detail is sharp, making monitoring and control more precise than ever.

- Responsive Touch Technology: With capacitive and resistive touchscreens, these HMIs offer responsive input, whether you’re wearing gloves or working in dusty environments.

- Built for the Toughest Conditions: Durable, scratch-resistant screens with IP65/IP66 ratings stand up to industrial wear and tear, ensuring long-lasting performance.

Seamless Connectivity

- Multi-Channel Communication: Equipped with Ethernet, USB, and RS-232/485 ports, these HMIs connect effortlessly with your PLCs, sensors, and other systems. Not only do they provide robust connectivity, but they also excel at processing and translating data from these sources into a visual format that operators can easily understand on the HMI screen.

Once the data is visually represented, operators can interact with the interface to monitor and manage industrial processes efficiently. This interaction is more than just passive observation; operators can actively send commands back to the PLCs via the HMI. This two-way communication ensures that all system processes are under precise control, enhancing operational efficiency and reliability.

By combining seamless connectivity with intuitive data visualization and command capabilities, these HMIs transform complex industrial data into actionable insights, facilitating smooth and effective control over your entire system. - Protocol Versatility: Supports a wide range of communication protocols, including Modbus, Profinet, and Ethernet/IP, ensuring smooth integration across your network.

- Remote Access Capabilities: Manage your systems from anywhere with remote monitoring features, giving you control and oversight even when you’re offsite.

Customization and Control

- Tailored User Interfaces: Design custom dashboards and controls that match your operational workflow, with intuitive software that’s easy to master.

- Global Readiness: Multi-language support ensures that your HMI is accessible to a diverse workforce, making it a versatile tool for global operations.

- Real-Time Data Insights: Advanced data logging and reporting features keep you informed with up-to-the-minute performance metrics, aiding in proactive decision-making.

Toughness in Any Environment

- All-Weather Reliability: Operates seamlessly in temperatures from -20°C to 60°C, ensuring your system remains functional in extreme conditions.

- Humidity-Resistant: Engineered to function effectively in environments with up to 90% humidity, safeguarding performance in challenging conditions.

- Protected Against the Elements: High IP ratings shield your HMIs from dust, water, and contaminants, making them ideal for the harshest industrial settings.

- Engineered for Stability: Built to endure vibrations and shocks, these HMIs maintain stable operation even in the most demanding environments.

Compliance and Safety

- Certified for Peace of Mind: Adheres to international safety and quality standards like CE, UL, and RoHS, ensuring your operations are compliant and secure.

- Integrated Safety Features: Includes essential safety mechanisms like emergency stops and password protection, providing an additional layer of security for your operations.

Scalable and Future-Ready

- Expandable Architecture: Modular designs allow for easy upgrades and expansion, so your HMI can evolve alongside your business needs.

- Adaptable I/O Options: Expand your control capabilities with additional I/O modules, perfectly suited for scaling your system as requirements grow.

- Ahead of the Curve: Built with future-proof technology, these HMIs ensure long-term compatibility with emerging industrial trends, keeping your operations at the cutting edge.

Enhanced User Experience

- Designed for Ease: User-friendly interfaces minimize training time and reduce the likelihood of errors, helping your team get up to speed quickly.

- Gesture-Based Controls: Multi-touch functionality brings consumer-grade ease of use to the industrial sector, enhancing interaction and control.

- Instant System Feedback: Real-time status updates and alerts provide immediate insights, allowing for quick adjustments and efficient operation.

These features make Industrial HMIs an essential asset for any operation aiming to enhance productivity, ensure reliability, and stay ahead in the rapidly evolving landscape of industrial automation.

Best Practices for Optimizing Industrial HMI Performance

To fully leverage the capabilities of your Industrial HMIs, it’s essential to implement strategies that ensure their longevity, efficiency, and safety. These interfaces are the nerve center of your automation system, designed to withstand rigorous industrial conditions. By following these best practices, you can maximize their effectiveness, reduce downtime, and maintain smooth operations across your facility.

- Precision Handling: During installation, treat HMIs with care to avoid damaging the display or internal circuitry. Proper handling preserves the device’s functionality and extends its lifespan.

- Strategic Placement: Position HMIs in areas that minimize exposure to extreme temperatures, moisture, and contaminants. This strategic placement ensures reliable performance and reduces the risk of damage.

- Secure Electrical Connections: Verify that all electrical connections are tight and secure, reducing the chance of communication errors or malfunctions. Reliable connections are key to maintaining uninterrupted operations.

- Maintain Optimal Cooling: Ensure adequate ventilation around your HMIs to prevent overheating. Consider implementing additional cooling solutions if your environment is particularly challenging, to protect sensitive components.

- Safeguard Against Power Surges: Install surge protection and proper grounding to defend your HMI against electrical spikes, which can cause catastrophic failures.

- Keep Software Up-to-Date: Regularly update your HMI software to access new features, improve security, and maintain optimal system performance. Staying current with updates is crucial for long-term reliability.

- Implement Routine Maintenance: Schedule regular maintenance checks to detect and resolve issues before they escalate. Routine inspections help you avoid unexpected breakdowns and maintain high efficiency.

At Uni Regal Corp., we understand the importance of keeping your HMIs in peak condition. Our expert team is here to provide the guidance and support you need to maintain top-tier performance in your automation systems.

Contact us today to discover how we can help you achieve seamless, reliable operations with our range of high-quality HMIs.

Why Industrial HMIs Are a Game-Changer

Industrial HMIs are more than just a control panel—they’re the central hub of your automation strategy, offering distinct advantages that elevate your operations to new heights:

- Intuitive User Experience: With sleek, touch-sensitive screens and customizable layouts, Industrial HMIs make it easy for operators to navigate complex systems, reducing errors and speeding up training times.

- Instant Operational Insights: HMIs provide real-time monitoring and data visualization, giving your team immediate access to critical information that drives faster, more informed decision-making.

- Effortless System Integration: Designed to work seamlessly with a wide range of automation equipment, HMIs support multiple protocols, ensuring flawless communication between all components of your system.

- Built-In Safety Mechanisms: Equipped with advanced safety features like emergency shutdowns and secure access controls, HMIs help protect both your workforce and your machinery from unforeseen risks.

- Tailored to Your Needs: Whether you’re managing a small operation or a sprawling industrial complex, HMIs offer flexible customization options, allowing you to design interfaces that perfectly match your specific operational requirements.

These features make Industrial HMIs indispensable for companies looking to streamline processes, enhance safety, and stay ahead in a competitive industry.

Empowering Industries with Industrial HMIs

Industrial Human-Machine Interfaces (HMIs) are the catalysts for revolutionizing automation across diverse sectors. Combining intuitive design with powerful capabilities, Industrial HMIs are the essential tools for businesses aiming to elevate their operational excellence and remain competitive. Let’s explore how these dynamic interfaces are redefining industries:

Transforming Manufacturing

- Efficient Production Coordination: Industrial HMIs act as the command center for manufacturing lines, ensuring every process is synchronized to boost productivity and minimize downtime.

- Advanced Robotic Interaction: These interfaces enhance the precision and speed of robotic systems, streamlining complex manufacturing tasks with ease.

- Proactive Quality Assurance: HMIs monitor and adjust processes in real-time, maintaining product quality at every stage and reducing waste.

Revolutionizing Chemical Processing

- Exact Process Control: Industrial HMIs orchestrate chemical reactions with pinpoint accuracy, ensuring safe and consistent outcomes in every batch.

- Uncompromising Safety Management: Acting as the vigilant overseers, HMIs continuously monitor critical systems to prevent accidents and ensure a safe working environment.

- Eco-Conscious Operations: HMIs help chemical plants achieve sustainability by optimizing processes to reduce waste and adhere to environmental standards.

Enhancing Energy Management

- Smart Energy Distribution: Industrial HMIs manage energy flows with precision, minimizing waste and ensuring a reliable power supply across all operations.

- Seamless Renewable Integration: Whether dealing with solar, wind, or hybrid systems, HMIs integrate renewable energy sources effortlessly into existing grids.

- Optimized Energy Storage: These interfaces fine-tune energy storage systems, balancing supply and demand to maintain grid stability.

Optimizing Oil and Gas Operations

- Precision in Extreme Conditions: Industrial HMIs ensure that oil and gas operations, whether offshore or onshore, run efficiently and safely in even the most challenging environments.

- Vigilant Pipeline Monitoring: HMIs continuously track pipeline integrity, preventing leaks and ensuring the secure transport of resources.

- Refinement Process Excellence: These interfaces fine-tune refining operations, ensuring that output meets the highest quality standards while maximizing efficiency.

Advancing Pharmaceutical Production

- Precision Dosage Control: Industrial HMIs ensure that every pharmaceutical product is manufactured with exact precision, safeguarding efficacy and safety.

- Streamlined Compliance: HMIs automate the tracking and documentation of every production step, making regulatory compliance straightforward and reliable.

- Sterility Assurance: Maintaining a sterile production environment is critical, and HMIs play a key role in ensuring contamination-free manufacturing.

Innovating Automotive Manufacturing

- Precision Assembly and Control: Industrial HMIs oversee the intricate assembly processes in automotive manufacturing, ensuring that every component is perfectly placed.

- Flawless Finishing Processes: These interfaces manage the complexities of painting and finishing, ensuring every vehicle meets the highest aesthetic standards.

- Comprehensive Testing and Validation: Before vehicles leave the factory, HMIs ensure they undergo rigorous testing to meet all performance and safety criteria.

Enhancing Water Management

- Effective Filtration Control: Industrial HMIs ensure water purification systems operate efficiently, delivering clean and safe water consistently.

- Reliable Pump Station Operations: These interfaces manage the operation of pump stations, ensuring the smooth handling of both water supply and wastewater treatment.

- Precision Chemical Dosing: HMIs control chemical treatments with accuracy, ensuring that water quality meets all regulatory standards.

Advancing Food and Beverage Processing

- Consistent Product Quality: Industrial HMIs are integral to maintaining high standards in food and beverage production, ensuring uniform quality in every batch.

- Efficient Packaging Solutions: Speed and precision are vital in packaging, and HMIs ensure that every product is packaged with care and accuracy.

- Optimal Temperature Management: HMIs monitor and control temperature settings, ensuring that food and beverages are stored and processed at the correct temperatures to maintain safety and quality.

Redefining Building Automation

- Energy-Efficient Climate Management: Industrial HMIs optimize HVAC systems, balancing energy consumption with occupant comfort, making buildings smarter and more sustainable.

- Adaptive Lighting Controls: These interfaces adjust lighting based on occupancy and natural light levels, reducing energy usage while maintaining a comfortable environment.

- Integrated Security Systems: From access control to surveillance, HMIs coordinate building security, ensuring a safe and secure environment for all occupants.

Streamlining Transportation Infrastructure

- Reliable Rail Operations: Industrial HMIs manage rail signaling and controls, ensuring trains operate smoothly and on time.

- Optimized Traffic Flow: These interfaces help manage city traffic, reducing congestion and improving the efficiency of urban transportation systems.

- Efficient Airport Management: From baggage handling to passenger flow, HMIs streamline airport operations, enhancing both safety and efficiency.

Industrial HMIs are not just interfaces; they are the backbone of modern automation. With their advanced features and adaptability, Industrial HMIs empower businesses to future-proof their operations and achieve new levels of innovation and efficiency.

The Ultimate Guide to Selecting Industrial HMI Components

Choosing the right Industrial HMI components is crucial for creating an automation system that’s efficient, reliable, and ready for the future. Here’s your easy-to-follow guide to making the smartest choices:

1. Define Your Automation Goals

- What’s Your Vision? Start by clarifying what you want to achieve—whether it’s improving machine control, enhancing user experience, or optimizing process monitoring, knowing your endgame is key.

- Display Essentials: Consider the display size and type. Do you need a compact interface for tight spaces, or a larger, high-resolution screen for detailed data visualization?

- Control Dynamics: Think about the level of interaction your system requires—whether it’s basic touch commands or complex multi-touch gestures, ensure your HMI meets these needs.

2. Consider Your Environment’s Demands

- Built to Last: Will your HMIs be exposed to extreme conditions like heat, moisture, or dust? Choose components designed to withstand harsh industrial environments.

- Durability Counts: Ensure your HMI can handle the physical demands of your setting, from constant vibration to potential impacts and daily use.

3. Choose the Right HMI Series

- Essential Series: Ideal for straightforward applications that need reliable performance without the extra features.

- Advanced Series: Best for systems requiring robust processing, enhanced graphics, and versatile connectivity.

- Elite Series: Tailored for high-demand environments, offering top-tier performance, extensive customization, and in-depth diagnostics.

4. Ensure Strong Connectivity and Communication

- Protocol Savvy: Make sure your HMI supports the necessary communication protocols, like Modbus, Profinet, or EtherNet/IP, to guarantee smooth integration with your system.

- Data Integration: For data-heavy operations, choose HMIs that offer rapid processing and cloud connectivity to keep you ahead in the digital age.

5. Focus on Easy Programming and Integration

- User-Friendly Setup: Opt for HMIs compatible with standard programming languages to streamline setup and avoid unnecessary complications.

- Hassle-Free Integration: Look for HMIs that seamlessly fit into your existing infrastructure, whether they’re connecting with legacy systems, SCADA, or third-party devices.

6. Don’t Overlook Safety

- Safety First: Ensure your HMI includes essential safety features like emergency stops, secure access, and real-time alerts to safeguard your operations.

- Certified Compliance: Check that your HMI meets industry-specific safety standards (such as CE, UL, or IP ratings) to ensure they’re equipped for your environment.

7. Think About the Long-Term Value

- Total Value: Weigh the long-term benefits like energy efficiency, minimal downtime, and low maintenance against the initial cost. The least expensive option isn’t always the most cost-effective in the long run.

- Future-Ready: Select HMIs that offer easy upgrades or expansion capabilities to ensure your system can evolve as your needs grow.

8. Insist on Quality Vendor Support

- Dependable Tech Support: Choose a vendor that offers round-the-clock technical support, comprehensive training, and detailed documentation to help you maximize your HMIs’ potential.

- Warranties and Service: Make sure your vendor provides strong warranty coverage and maintenance services to protect your investment over the years.

Follow these guidelines, and you’ll be set to select Industrial HMI components that align perfectly with your operational goals, creating a reliable, scalable, and future-proof automation system that drives your business forward.

6. Advanced Safety Features

Ultimate Safety Assurance: Elevate your system’s security with state-of-the-art safety features like emergency stop controls, safety interlocks, and real-time fault detection. These features are designed to intervene when needed, ensuring that your operations stay safe and continue running smoothly under any circumstances.

Compliance You Can Trust: Rest easy knowing your HMIs meet the highest safety standards, including CE, UL, and IEC certifications. This isn’t just about compliance—it’s about securing your operations with the best safety practices in the industry.

7. Tailored User Interfaces

Custom HMI Experience: Design HMI screens that are perfectly aligned with your operational needs. These customized interfaces offer real-time control, allowing you to make quick adjustments and keep everything running efficiently.

Access Control: Implement security protocols within your HMI to manage who can access critical functions. This ensures that sensitive areas of your system are protected from unauthorized access and potential errors.

Industrial HMIs are renowned for their adaptability and advanced features, making them ideal for optimizing your automation systems. These capabilities ensure that your operations are not only efficient but also secure and scalable.

Customizing Industrial HMI Solutions

Industrial HMIs are designed to be highly adaptable, allowing you to customize them to meet the specific needs of your operation. Here’s how you can fine-tune HMI solutions to perfectly fit your industrial environment:

1. Modular Interface Flexibility

Build Your Ideal System: Craft an HMI setup that evolves with your needs by choosing a modular design. Add or adjust components as necessary, whether you’re scaling up or optimizing an existing system.

Scalable Growth: Expand your HMI capabilities by integrating additional display panels, communication modules, or specialized features as your operations grow, ensuring your system remains flexible and future-ready.

2. Customized Programming

Tailored Interface Logic: Develop HMI programs that directly address your specific challenges. Custom logic enables you to enhance both efficiency and performance, aligning your HMI with your exact processes.

Industry-Specific Solutions: Whether in pharmaceuticals, automotive, or food processing, program your HMI to handle specialized tasks, streamlining operations and maintaining high productivity.

3. Enhanced Connectivity

Seamless Integration: Ensure your HMIs connect effortlessly with your existing systems using industry-standard protocols like Modbus, Profinet, or EtherNet/IP. This guarantees smooth communication across your entire operation.

Remote Access Control: Monitor and control your operations from anywhere. With remote HMI capabilities, you can make real-time adjustments to your systems, ensuring continuous efficiency no matter where you are.

4. Specialized Module Integration

Precision Control: Integrate specialized modules that offer high-speed data processing and exact control, ensuring your systems operate at peak performance, even under complex conditions.

Custom I/O Configurations: Create a tailored I/O setup that combines analog, digital, and specialty modules, perfectly matching your operational needs and maximizing system effectiveness.

5. Environmental Adaptability

Built for Harsh Conditions: Choose HMIs that are designed to withstand extreme industrial environments, from high temperatures to dusty factory floors, ensuring durability and reliability.

Protective Enclosures: Equip your HMI components with protective casings and coatings that shield them from moisture, dust, and corrosive elements, ensuring they stay in top condition for the long haul.

How to Pick the Perfect Supplier for Industrial HMIs

Choosing the right supplier for your Industrial HMI needs is critical to the success and longevity of your automation projects. Here’s a creative and practical guide to help you make the best choice:

Seek out a supplier with deep industry knowledge. They should offer a diverse range of Industrial HMIs, from entry-level models to advanced systems, and be skilled at customizing solutions to meet your specific needs. A supplier who understands the intricacies of HMI integration will ensure that your systems work together flawlessly, just like a well-rehearsed orchestra.

Quality should be at the forefront. Ensure your supplier meets international standards and certifications, guaranteeing that their Industrial HMIs are built to last. They should also have a thorough understanding of materials and manufacturing processes, so they can recommend the most durable and reliable components for your operations.

A great supplier offers more than just top-notch products—they provide exceptional technical support from start to finish. Whether you’re choosing the right HMI or fine-tuning your setup, they should be there to help. Don’t overlook customer reviews and testimonials; they give you a real-world view of the supplier’s reliability and customer service.

Timing is everything. Your supplier should be known for delivering Industrial HMIs on schedule, keeping your projects on track. Beyond delivery, look for a supplier who offers strong after-sales support, including warranties and maintenance services, to protect your investment and ensure your systems continue to operate at peak performance.

Final Takeaway

Industrial HMIs are the ultimate tools in automation—adaptable, intuitive, and essential for driving efficiency in everything from precision manufacturing to smart building systems.

At Uni Regal Corp., we’re committed to being your trusted partner, offering a diverse range of Industrial HMI solutions that are ready to meet your specific requirements. Whether you need globally trusted brands or custom-tailored interfaces, our expertise ensures you find the perfect fit for your projects. Our team of specialists is here to help you choose the ideal HMI, ensuring seamless automation that keeps your operations running at peak performance.

Streamline Your Industrial HMI Solutions

Say goodbye to the complexities of managing your HMI needs with our expert solutions. With extensive industry experience, we craft and deliver tailored HMI systems that seamlessly integrate into your operations. By handling everything in-house, from sourcing to quality control, we ensure exceptional standards at prices that keep you ahead of the game.

Why settle for less on your automation journey? Partner with us and explore Industrial HMI solutions that are efficient, dependable, and designed to give you a competitive advantage.