Unleash Precision with Our Servo Motors

Looking to take your operations to the next level? Uni Regal Corp. has you covered with servo motors that aren’t just tough—they’re downright unstoppable. Our servo motors deliver the precision and control you need to keep everything on your factory floor running like a well-oiled machine. Think of them as the pulse of your operation—ensuring every movement is smooth, every task is precise, and every piece of equipment works in perfect harmony. We know the last thing you want is downtime, so we’ve made sure our servo motors integrate seamlessly with your existing systems, letting you focus on what really matters: keeping your production line ahead of the game. With Uni Regal, you’re not just buying a motor—you’re investing in a partner that’s as reliable and hardworking as you are.

15

Years of experience

Your Ultimate Source for High-Precision Servo Motors

“Simplify Your Servo Motor Sourcing with Expertise You Can Trust and Reliability You Can Count On”

When it comes to driving your operations forward, you need more than just another supplier—you need a partner who speaks the language of industrial automation and delivers exactly what you need, minus the hassle. At UniRegal Automation, we’re all about getting your systems the precision, power, and control they crave, with top-of-the-line servo motors from industry legends like Mitsubishi, ABB, and Siemens.

We know the drill—finding the right servo motor for the job can feel like a guessing game. You need something that not only fits but performs seamlessly with your current setup. Whether you’re on a tight schedule or need expert advice, we’ve got you covered. Our team dives deep to understand your needs, helping you zero in on the perfect motor, sourced directly from the top brands you trust.

But we don’t stop at just delivering the goods. We get how crucial it is to have everything running like clockwork—quick delivery, reliable stock, and a support team that’s got your back. That’s why we’ve streamlined everything from logistics to customer service, so your operations keep humming without a hitch. With Uni Regal Corp., you’re not just getting a servo motor—you’re teaming up with a crew that’s just as committed to your success as you are.

- Expert Guidance: Leverage our deep industry know-how to pinpoint the ideal servo motor from top brands, perfectly tailored to your application.

- Genuine Products, Every Time: We only source from trusted manufacturers, ensuring you receive authentic, high-quality servo motors.

- Effortless Procurement: Experience a hassle-free purchasing process with our smooth logistics and flexible delivery options.

- Support That Stays With You: From choosing the right motor to post-purchase care, we’re with you every step of the way, ensuring everything runs smoothly.

- Extensive Inventory: Browse our wide range of servo motors, giving you the flexibility to find exactly what you need for any project.

- Dependable Delivery: We prioritize fast, reliable shipping, making sure your servo motors arrive on time and keep your projects on track.

Your Trusted Source for Servo Motors

Give your operations the precision they need with servo motors that perform under pressure. At Uni Regal Corp., we’re not just your supplier—we’re your partner in powering success. With top brands like Mitsubishi, ABB, and Siemens in our lineup, our servo motors are built to handle the most demanding industrial environments. You can count on us for motors that deliver unmatched accuracy and reliability, keeping your production running smoothly and downtime to a bare minimum.

Tailor Your Perfect Servo Motor Solution with Uni Regal Corp.

At Uni Regal Corp., we know that finding the right servo motor is crucial for keeping your operations smooth and precise. That’s why we’ve made it easy with a simple, four-step process that puts you in control, while we handle the heavy lifting.

Step 1.

Understand Your Precision Needs

Let’s kick things off by pinpointing exactly what your operations demand. Whether it’s ultra-precise motion control, handling heavy-duty tasks, or ensuring seamless integration with your current setup, we’re here to listen and offer the best advice.

Step 2.

Set Your Performance Goals

What’s your endgame? Are you looking to enhance accuracy, reduce downtime, or push productivity to new heights? Lay out your goals, and we’ll align our solutions to hit every target with precision.

Step 3.

Select Your Servo Motor Components

Dive into our extensive range of servo motors from trusted brands like Mitsubishi, ABB, and Siemens. Pick the models that not only meet your specs but also tackle your toughest challenges head-on.

Step 4

Lock It In and Power Up

Finalize your choices—confirm the perfect motors and quantities, ensuring each one fits seamlessly into your operation. Then sit back and watch as your systems come to life with unparalleled performance.

Consult with our Engineers

Frequently asked questions

The Questions about servo motors, Answered

We know that picking the right servo motor can feel like a big deal. That’s why we’ve tackled the most common questions our clients ask, so you’re fully prepped to make the best choice for your operations. Got something else on your mind? Just give us a shout—we’re here to help.

It’s not just about the specs—it’s about understanding your exact needs, from precision and speed to how it fits with your existing setup. We’re here to help you cut through the noise and find the servo motor that ticks all the boxes.

We’ve got the big names like Mitsubishi, ABB, and Siemens—all known for their reliability and top-notch performance. Whether you need unbeatable accuracy, rugged durability, or cutting-edge control features, we’ll help you pick the brand that’s just right for your goals.

Worried about a bumpy ride? Don’t be. We’ll work with you to ensure your new servo motor fits like a glove with your existing setup. Our experts are on hand to guide you through the process, making integration a breeze.

We know installation can be tricky, but don’t sweat it—we’ve got your back. From clear setup instructions to on-call support, we’ll make sure your servo motor is up and running without a hitch. If something’s not right, we’re here to fix it.

We get it—downtime isn’t an option. That’s why we’re all about fast, reliable delivery, keeping your operations on track without skipping a beat. We’ll keep you in the loop with shipping times, so there’s no guesswork involved.

Costs can vary, but we’re all about giving you the best bang for your buck without skimping on quality. We’ll work with you to find a servo motor that fits your budget while meeting all your performance needs.

You bet. Our support doesn’t end when the sale’s done. Whether it’s troubleshooting an issue or offering maintenance tips, we’re here to make sure your servo motor stays in top shape.

We back our servo motors with solid warranties because we believe in their quality. You can rest easy knowing your investment is protected, giving you peace of mind long after your purchase.

Bring it on. Whether you’re dealing with extreme conditions, demanding precision, or specific safety requirements, we’ve got a servo motor that’s up to the task. Let’s solve that challenge together.

Our servo motors are built tough to handle whatever you throw at them. With proper care, they’ll keep delivering reliable performance for years to come. We’ll help you pick the model that’s built to last in your environment.

Absolutely! We’re here to ensure your servo motors are installed and programmed correctly, integrating smoothly into your system and hitting your operational targets right from the start.

To keep your servo motors running at their best, make sure to keep them clean and free of dust buildup. Monitor temperature levels to prevent overheating, and regularly check connections for any signs of wear and tear. Stay on top of firmware updates, avoid pushing your motors beyond their limits, and don’t forget to schedule routine professional maintenance. A little care goes a long way in ensuring your motors deliver smooth, reliable performance day in and day out.

Your Ultimate Guide to Finding the Right Servo Motors

Ready to give your automation systems the precision they deserve? Servo motors are the heartbeat of any smooth-running operation, delivering the exact control you need to keep everything on point. In this guide, we’ll show you how the right servo motors can transform your business, offering the reliability and finesse required for even the most demanding industrial tasks.

We’ll break down the flexibility of servo motors—whether you’re enhancing complex processes, maximizing efficiency, or upgrading outdated equipment. This guide is packed with savvy tips and insights to help you zero in on the servo motor that perfectly aligns with your operational goals.

And let’s not forget the long-term wins—investing in top-tier servo motors isn’t just about today’s performance. It’s about gearing up for the future, ensuring your systems are not only efficient but also robust enough to tackle whatever the fast-paced world of industrial automation throws your way.

Table of Contents

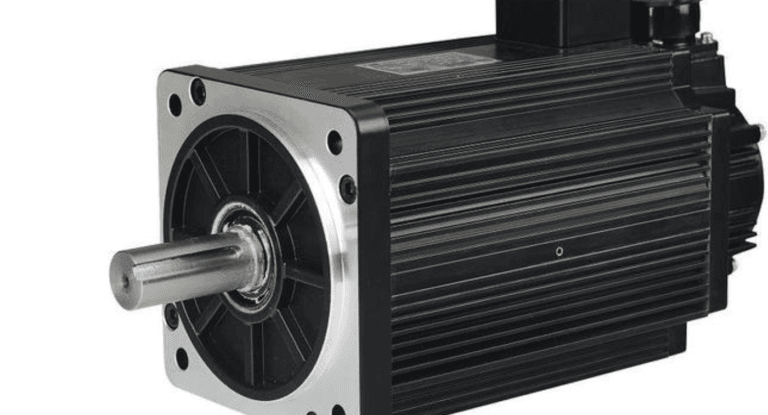

What Are Servo Motors?

Imagine servo motors as the brains behind your machinery—ensuring every move is precise, every operation smooth, and every task completed with pinpoint accuracy. These powerful devices are essential for controlling motion, offering the exact torque, speed, and position your equipment demands. Whether you’re driving robotic arms, operating CNC machines, or controlling conveyor systems, servo motors give you the finesse to adapt and excel in real-time.

Built to thrive in tough industrial environments, servo motors come packed with features like advanced feedback systems, overload protection, and energy-efficient designs. They’re engineered to keep your operations running seamlessly, even when conditions are challenging, making them the go-to solution for businesses where precision and reliability are non-negotiable.

And the best part? Servo motors integrate effortlessly with your existing automation setup—working in harmony with PLCs, sensors, and control systems. This means you can fine-tune operations and optimize performance right from your control panel, keeping your processes sharp and your machinery in peak condition.

In a nutshell, servo motors are your trusted partners in precision. They elevate process control, enhance flexibility, and ensure your operations are always on point. For any industry where accuracy and efficiency are key, servo motors aren’t just helpful—they’re indispensable.

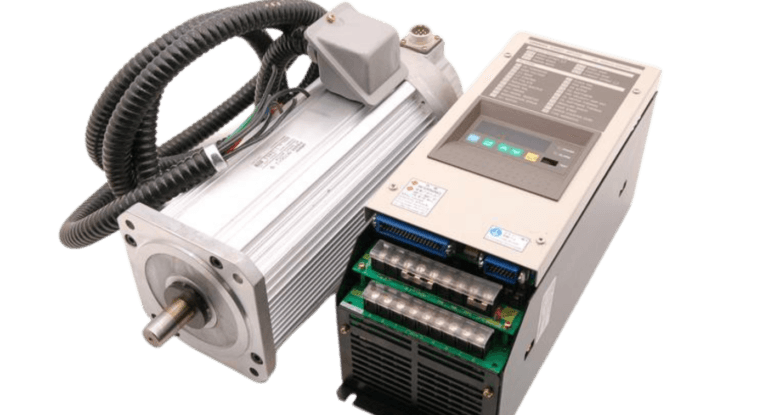

Essential Features to Look for in Industrial Servo Motors

Servo motors are the backbone of precision and efficiency in industrial automation. They’re more than just components—they’re your secret weapon for smooth, reliable operations. Let’s dive into the must-have features that make these motors essential for keeping your systems running at their best:

Precision That Hits the Mark

- Versatile Torque Options: Whether it’s delicate tasks or heavy lifting, these servo motors adapt to a wide range of torque demands, giving you the precise control needed for any job.

- Smooth Performance: No more jerky movements or unnecessary wear. These motors ensure every action is fluid and precise, reducing strain on your equipment and extending its lifespan.

- Instant Adaptability: When conditions change, you need a motor that can keep up. These servo motors offer rapid response times, adjusting on the fly to maintain seamless operations.

- Energy-Saving Smarts: Why waste energy? These motors are engineered to optimize power use, cutting down on your energy bills while maintaining top performance.

Stay Connected and in Command

- Effortless Integration: Connecting these motors to your current systems is a breeze, thanks to support for popular communication protocols like Ethernet and Modbus.

- Protocol-Friendly: No matter your setup, these servo motors play well with others, ensuring smooth communication and operation with your existing automation systems.

- Remote Control Ready: Need to make adjustments from afar? No problem. These motors come with remote monitoring capabilities, so you’re always in control, no matter where you are.

Customization Without Complication

- Tailor-Made for You: Adjust everything from speed to position with ease. These motors are designed to be as flexible as your needs, giving you the ability to fine-tune performance effortlessly.

- Growth-Ready: Planning to scale? These motors are built to expand alongside your operations, making them a perfect fit whether you’re starting small or going big.

- User-Friendly Design: Forget complicated setups—these motors come with intuitive interfaces that make installation and adjustments simple and straightforward.

Built to Endure, No Matter What

- All-Weather Warriors: From scorching heat to freezing cold, these servo motors are designed to keep going, ensuring your operations stay on track in any environment.

- Rugged Reliability: Dust, moisture, and vibration are no match for these motors. Built tough, they’re ready to tackle the harshest conditions without missing a beat.

- Durable by Design: These motors are made to last, with features that protect against overloads and ensure consistent performance, even in the most demanding situations.

Safety and Standards You Can Trust

- Globally Certified: Rest easy knowing these motors meet international safety standards like CE, UL, and IEC, ensuring they’re up to the task no matter where you operate.

- Safety First Features: From overheat protection to emergency stop functions, these motors are equipped with safety measures that protect both your equipment and your team.

Ready for the Future

- Modular and Scalable: Expand and upgrade with ease. These servo motors are designed to grow with your needs, making them as adaptable as your business demands.

- Expandable I/O: Add new capabilities as your operations evolve. These motors offer expandable I/O options that let you enhance functionality as needed.

- Tech-Savvy Solutions: Stay ahead of the curve with motors packed with the latest technology, ensuring your systems are always at the cutting edge.

Designed for You

- Quick Setup, Easy Use: Get started faster with user-friendly setups and interfaces that make configuration a breeze.

- Instant Insights: Real-time diagnostics keep you informed, allowing for quick tweaks and ensuring everything runs smoothly without surprises.

- Whisper-Quiet Operation: Enjoy a quieter workspace with motors designed for silent efficiency, enhancing comfort without compromising power.

With these features, servo motors are more than just equipment—they’re essential partners in driving precision, efficiency, and reliability in your industrial operations.

Maximizing Performance: Top Tips for Using Your Servo Motors

Your servo motors are the precision drivers of your automation setup, ensuring accurate control and seamless operation. But to truly maximize their capabilities, it’s important to take a few strategic steps. By following these best practices, you’ll keep your servo motors performing at their peak, reduce potential downtime, and ensure consistent, reliable performance.

- Install with Precision: Take the time to carefully install your servo motors, paying attention to alignment and secure mounting. Proper installation ensures your motors function smoothly and extend their lifespan.

- Position Strategically: Placement is key. Install your servo motors in clean, stable environments with controlled temperatures. Keeping them free from dust and moisture helps maintain their precision and efficiency.

- Check Alignment: Regularly verify that the motor shaft alignment is correct. Misalignment can lead to wear and tear, reducing the motor’s lifespan and efficiency.

- Maintain Optimal Cooling: Ensure your servo motors have adequate ventilation. If they’re operating in a high-temperature environment, additional cooling systems can help prevent overheating and maintain performance.

- Protect from Voltage Surges: Voltage spikes can be harmful. Protect your servo motors with surge protectors and ensure proper grounding to avoid unexpected damage.

- Keep Firmware Updated: Firmware updates are crucial for maintaining optimal motor performance. Regularly updating ensures you benefit from the latest improvements and security enhancements.

- Routine Inspections: Don’t wait for issues to arise. Schedule regular inspections to catch early signs of wear or misalignment, keeping your servo motors in top condition.

At Uni Regal Corp., we understand that maintaining your servo motors is crucial to your operation’s precision and efficiency. Our team is dedicated to helping you optimize performance and ensure your systems run smoothly with our top-quality servo motors.

Contact us today to discover how we can help you achieve reliable, precision-driven operations with our trusted servo motor solutions.

Why Servo Motors ARE CRUCIAL?

Servo motors are more than just components—they’re the precision drivers of your operation, offering benefits that can significantly boost your efficiency and reliability:

- Precision Control: Servo motors provide accurate control over movements, ensuring your machinery operates exactly as needed. This level of precision helps reduce errors, enhance product quality, and minimize material waste, directly impacting your bottom line.

- Swift Adaptability: These motors respond instantly to changes in commands, keeping your systems flexible and adaptable to varying demands. This quick reaction time helps avoid disruptions and ensures smooth, continuous operation.

- Effortless System Integration: Designed to seamlessly integrate with your existing automation framework, servo motors are compatible with a wide range of communication protocols, ensuring all components work together without a hitch.

- Robust Safety Features: With built-in protections such as overload monitoring and automatic shutdowns, servo motors protect your equipment from unexpected failures, reducing the risk of costly downtime and extending the life of your machinery.

- Custom-Fit Solutions: Every operation has its unique challenges, and servo motors offer the flexibility to be tailored to your specific needs. Whether it’s adjusting speed, torque, or positioning, these motors can be fine-tuned to optimize your entire process.

These qualities make servo motors indispensable for companies that prioritize precision, adaptability, and long-term reliability in their industrial operations.

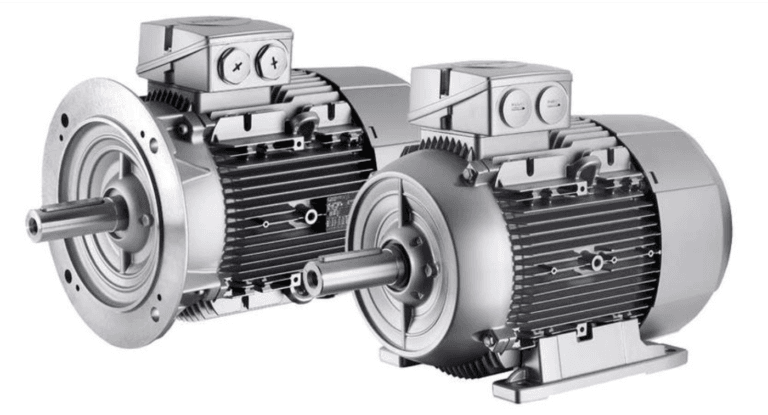

Driving Industrial Success with Servo Motors

Servo motors are the unsung champions driving precision and innovation across diverse industries. Offering unmatched control and reliability, these versatile devices are essential for businesses aiming to stay competitive and maintain flawless operations. Let’s explore how servo motors are transforming industries:

Elevating Manufacturing Excellence

- Precision Engineering: Servo motors provide exact control over movement, ensuring every machine operates with flawless precision. This results in faster production, less mechanical stress, and optimized energy use.

- Effortless Efficiency: Beyond powering your machinery, servo motors streamline energy consumption, helping you cut costs while keeping your production lines running smoothly.

- Reliable Uptime: With responsive performance and built-in safeguards, servo motors minimize downtime, ensuring your operations stay on track without disruptions.

Refining Chemical Processing

- Exact Process Control: Servo motors deliver precise adjustments for chemical reactions, ensuring consistency, safety, and adherence to stringent standards with every batch.

- Safety at the Forefront: Equipped with advanced safety features, these motors vigilantly monitor your processes, minimizing risks and maintaining a secure work environment.

- Sustainable Operations: By optimizing energy use and reducing waste, servo motors help chemical plants achieve greener, more efficient operations without compromising on productivity.

Enhancing Energy Management Systems

- Precision Power Distribution: Servo motors regulate power flow with pinpoint accuracy, reducing energy waste and ensuring a reliable supply across all operations.

- Seamless Integration with Renewables: Whether integrating solar, wind, or other green energy sources, servo motors ensure smooth operation, maximizing the benefits of renewable energy.

- Optimized Energy Storage: Servo motors fine-tune energy storage systems, balancing supply and demand to keep your grid stable and efficient.

Optimizing Oil and Gas Operations

- Performance Under Extreme Conditions: Engineered for harsh environments, servo motors ensure oil and gas operations run efficiently and safely, no matter the conditions.

- Pipeline Integrity Monitoring: Servo motors provide continuous monitoring of pipeline systems, helping prevent leaks and ensuring safe resource transport.

- Precision in Refining: These motors optimize refining processes, maximizing output quality while ensuring operational efficiency and safety.

Advancing Pharmaceutical Manufacturing

- Stringent Quality Control: Servo motors deliver the exacting control needed for pharmaceutical production, ensuring every product meets the highest quality standards.

- Simplified Compliance: With integrated data logging and precise process control, servo motors make it easier to meet regulatory requirements and maintain compliance.

- Maintaining Sterility: Servo motors play a critical role in preserving sterile environments, preventing contamination and ensuring the safety and efficacy of pharmaceutical products.

Driving Automotive Innovation

- Precision in Assembly: Servo motors keep automotive assembly lines running with unmatched accuracy, ensuring every component is perfectly placed and each vehicle meets exacting standards.

- Perfect Finishes: From painting to finishing, servo motors manage complex processes with precision, ensuring every vehicle leaves the line looking impeccable.

- Rigorous Testing and Quality Assurance: Servo motors ensure that every vehicle undergoes thorough testing, meeting all safety and performance benchmarks before hitting the road.

Enhancing Water Management

- Optimized Pump Performance: Servo motors ensure efficient operation of water pumps, delivering consistent flow while minimizing energy consumption.

- Reliable Filtration Systems: These motors keep filtration processes running smoothly, ensuring the delivery of clean, safe water at all times.

- Precision in Treatment Processes: With accurate control over chemical dosing, servo motors help maintain water quality, meeting even the most stringent regulatory standards.

Boosting Food and Beverage Production

- Consistency You Can Taste: Servo motors are vital in ensuring the uniformity and quality of food and beverage products, making sure every batch meets high standards.

- Efficient Packaging: Packaging lines run faster and more accurately with servo motors, ensuring products are packed efficiently and free of errors.

- Temperature Precision: Servo motors manage temperature controls with exactness, ensuring food and beverages are processed and stored under optimal conditions.

Transforming Building Automation

- Precision Climate Control: Servo motors optimize HVAC systems, balancing energy efficiency with comfort to create sustainable, efficient buildings.

- Dynamic Lighting Management: These motors adjust lighting systems based on occupancy and natural light, reducing energy consumption while maintaining the ideal environment.

- Integrated Security Systems: From access control to surveillance, servo motors coordinate building security, ensuring a safe and secure environment.

Streamlining Transportation Systems

- Rail Systems in Sync: Servo motors manage rail operations with precision, keeping trains running smoothly and on time.

- Optimized Traffic Control: These motors help manage urban traffic systems, reducing congestion and improving the efficiency of transportation networks.

- Efficient Airport Operations: Servo motors streamline airport functions from baggage handling to passenger processing, enhancing safety and efficiency.

Servo motors are more than just power components—they’re the backbone of industrial innovation. With advanced features and the adaptability to fit any industry, servo motors are key to staying competitive, efficient, and future-ready.

How to Select the Perfect Servo Motors?

Choosing the right servo motors is a pivotal step in building a resilient and forward-thinking automation system. Here’s a fresh approach to guide you through making the most informed decision:

1. Clarify Your Motion Requirements

- What’s Your Goal? Start by pinpointing exactly what you need—whether it’s achieving precise motion control, reducing energy consumption, or enhancing the overall efficiency of your system, having clear objectives is crucial.

- Torque and Speed Demands: Assess the specific torque and speed your application requires. Are you dealing with heavy-duty tasks or need high-speed precision?

- Precision Matters: Determine the level of precision you require—do you need basic control, or is advanced position and torque management essential for your operation?

2. Evaluate Your Environmental Needs

- Built to Last: Consider the conditions your motors will operate in—extreme temperatures, dust, or humidity. Choose models designed to thrive in challenging industrial environments.

- Endurance is Key: Ensure your servo motors can handle the physical demands of your setting, from constant vibrations to intense daily use.

3. Select the Appropriate Motor Series

- Basic Series: Best for straightforward applications where dependability is key, without unnecessary extras.

- Enhanced Series: Ideal for more intricate operations, offering improved energy efficiency, robust processing capabilities, and superior connectivity.

- Elite Series: Perfect for mission-critical environments, providing exceptional performance, full customization, and comprehensive diagnostics.

4. Focus on Connectivity and System Integration

- Protocol Compatibility: Verify that your servo motor supports the necessary communication protocols, such as EtherCAT, Modbus, or CANopen, for seamless system integration.

- Data-Driven Operations: For operations where data is crucial, opt for motors with advanced processing power and cloud capabilities to keep your systems running smoothly.

5. Simplify Setup and Implementation

- User-Friendly Configuration: Choose motors that are easy to set up and program, ensuring compatibility with standard programming languages to get your system operational quickly.

- Plug-and-Play Integration: Look for motors that easily integrate with your current infrastructure, whether they need to work with legacy systems, PLCs, or other devices.

6. Prioritize Safety and Compliance

- Safety First: Your servo motors should be equipped with safety features like overload protection, secure access controls, and real-time fault alerts.

- Industry Compliance: Ensure your motors meet industry-specific safety standards like CE, UL, or IP ratings, ensuring they’re suitable for your operational environment.

7. Plan for Future Growth

- Think Beyond Price: Don’t just focus on the initial cost—consider long-term savings through energy efficiency, reduced maintenance, and minimized downtime. A slightly higher investment now can lead to significant savings over time.

- Scalable Solutions: Choose motors that are adaptable and allow for easy upgrades or expansion, ensuring your system can evolve as your operational needs grow.

8. Insist on Strong Vendor Support

- Dependable Support: Select a vendor that offers reliable, around-the-clock support, thorough training, and clear documentation to help you get the most out of your servo motors.

- Comprehensive Warranties: Protect your investment with robust warranties and proactive maintenance services from a trusted supplier.

By adhering to these guidelines, you’ll be well-positioned to select servo motors that not only meet your current needs but also ensure your automation system is ready for future challenges, providing a robust, scalable, and reliable foundation for years to come.

6. Cutting-Edge Safety Measures

Uncompromising Safety: Safeguard your operations with advanced safety features like emergency stop functions, safety interlocks, and instant fault detection. These aren’t just bells and whistles—they’re crucial elements that step in to protect your system and ensure smooth operation, even in unexpected situations.

Certified Confidence: Feel secure knowing that your servo motors comply with the highest safety standards, including CE, UL, and IEC certifications. It’s not just about ticking a compliance box; it’s about ensuring your systems are protected by the best practices in industrial safety.

7. Personalized Control Interfaces

Customize Your Control: Design servo motor interfaces that fit your operational needs perfectly. These personalized controls allow you to make real-time adjustments, ensuring your systems are always optimized for peak performance.

Secure Your Settings: Implement strong security protocols within your servo motor systems to control who can access and modify critical settings. This ensures your operations remain protected from unauthorized changes, with only the right personnel having control.

Servo motors are celebrated for their versatility and state-of-the-art features, making them essential for fine-tuning your automation systems. These capabilities guarantee that your operations remain efficient, secure, and scalable.

Tailoring Servo Motor Solutions

Servo motors are engineered to be as adaptable as your needs, allowing you to customize them to meet your specific operational challenges. Here’s how you can adjust servo motor solutions to seamlessly fit your industrial environment:

1. Modular Adaptability

Configure to Your Needs: Build a servo motor setup that evolves with your requirements. Opt for a modular design that allows you to add or modify components as your system grows—whether scaling up or refining your existing operations.

Space for Expansion: Expand your servo motor capabilities with additional control modules, communication interfaces, or specialized features as your needs evolve, ensuring your system remains flexible and prepared for the future.

2. Customized Programming

Tailored Motion Logic: Develop servo motor programs that address your specific operational challenges. Custom logic allows you to fine-tune performance and efficiency, perfectly aligning your motors with your unique processes.

Industry-Specific Solutions: Whether in manufacturing, energy management, or water treatment, program your servo motors to handle specialized tasks, streamlining your operations and boosting productivity.

3. Enhanced Connectivity

Seamless Integration: Ensure your servo motors connect effortlessly with your existing systems using industry-standard protocols like EtherCAT, Modbus, or Profibus. This ensures smooth communication and coordination across your entire operation.

Remote Control: Monitor and adjust your systems from anywhere. With remote capabilities, you can make real-time adjustments to your servo motors, ensuring everything runs smoothly even when you’re offsite.

4. Specialized Module Integration

Precision at Its Peak: Integrate specialized modules that offer high-speed data processing and precise motion control, keeping your systems at peak performance, even in the most demanding applications.

Custom I/O Configuration: Design an I/O setup tailored to your needs by combining analog, digital, and specialty modules, maximizing your system’s efficiency and effectiveness.

5. Durability and Longevity

Built for the Harshest Conditions: Choose servo motors that can withstand the most challenging industrial environments, from extreme temperatures to dusty, corrosive conditions, ensuring they provide reliable performance over the long term.

Protected and Preserved: Equip your servo motors with robust enclosures that shield them from moisture, dust, and harsh elements, ensuring they stay in optimal condition for years to come.

Case Studies: Real-World Insights on Servo Motors

Selecting the right servo motor brand is critical for ensuring the success of your automation projects. Here’s feedback from customers who have used different brands, highlighting their experiences to help you make an informed decision:

“We’ve implemented Mitsubishi servo motors in our CNC machines, and the results have been remarkable. The motors offer precise control and speed, enhancing our machining accuracy. UniRegal Co. provided excellent support during the integration, making the process smooth and efficient.”

— David P., Head of Manufacturing, Precision Engineering

“Omron servo motors have been a game-changer in our robotics applications. Their torque control and smooth operation have significantly improved our production line efficiency. UniRegal Co.’s guidance in selecting the right models was invaluable, and their customer service has been consistently reliable.”

— Jessica T., Robotics Engineer, Electronics Manufacturing

“Siemens servo motors have proven to be incredibly durable in our chemical processing plant. They perform reliably even in tough conditions, which has minimized our downtime. UniRegal Co. was instrumental in helping us choose the correct configurations, ensuring our operations run smoothly.”

— Robert H., Plant Manager, Chemical Industry

“Yaskawa servo motors have excelled in our automated manufacturing systems, delivering exceptional precision and reliability. Their advanced control features have allowed us to optimize our processes, leading to significant productivity gains. UniRegal Co. helped us navigate the selection process, ensuring we got the most suitable motors for our needs.”

— Emily C., Engineering Director, Industrial Automation Solutions

Closing Thoughts

Servo motors are the heart of your automation systems—precise, reliable, and crucial for driving efficiency in everything from advanced manufacturing to complex robotics.

At Uni Regal Corp., we’re more than just a distributor—we’re your partner in achieving operational excellence. We offer a comprehensive selection of top-tier servo motors, tailored to meet your specific needs. Whether you’re looking for trusted global brands or require a customized solution, our expertise ensures you find the perfect match for your projects. Our team is dedicated to helping you navigate the options, ensuring you get the best servo motor to keep your systems running smoothly and at peak performance, no matter the challenge

Take the Stress Out of Servo Motor Selection

Feeling overwhelmed by the complexities of servo motors? Let us take the hassle out of the equation with our expert solutions. With years of industry know-how, we specialize in crafting customized servo motor systems that fit seamlessly into your operations. We manage everything in-house—from sourcing to quality assurance—so you get top-quality motors without the headache, all at prices that help you stay competitive.

Don’t let servo motor challenges slow you down. Partner with us to discover solutions that are not only efficient and reliable but also designed with your unique needs in mind. We’re here to make sure you stay ahead of the curve and keep your systems running smoothly, every step of the way.