In today’s competitive industrial automation landscape, choosing the right PLC brand is critical. This article is based on extensive research into global PLC brands, along with feedback from industry engineers and procurement professionals. Our 2024 list of recommended PLC brands will help you make well-informed decisions about quality, reliability, and functionality.

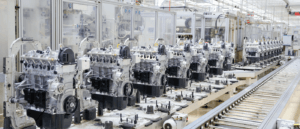

Siemens

Siemens is one of the most well-known PLC manufacturers globally, with its SIMATIC series widely used in automotive, manufacturing, and energy sectors.

Pros: Siemens PLCs are highly regarded for their performance, flexibility, and reliability, making them ideal for complex, large-scale automation projects. The TIA Portal software simplifies programming and system integration, allowing engineers to optimize and upgrade systems efficiently. The extensive range of expansion modules also supports future scalability.

Cons: The high cost and complexity of the system may require skilled personnel and additional training, which could increase overall implementation expenses.

Best for: large factory automation, automotive production lines, and smart manufacturing systems.

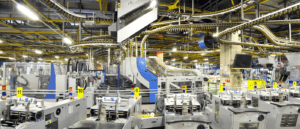

Mitsubishi Electric

Mitsubishi Electric is a trusted name in the automation industry, especially popular in Asia and among global manufacturers for its compact and efficient PLC solutions.

Pros: The FX and Q series from Mitsubishi excel in energy efficiency and high-speed performance, ideal for small to medium-sized industrial applications. These PLCs support various communication protocols like Ethernet and Modbus, making integration and data management easier. Mitsubishi’s high-speed processing and stable performance make it a preferred choice for many.

Cons: Some high-end models have limited support documentation, and after-sales service may vary by region, which could be an issue for remote locations.

Best for: automotive manufacturing, food processing, and semiconductor production.

Rockwell Automation (Allen-Bradley)

Allen-Bradley, produced by Rockwell Automation, is a leading PLC brand in the United States renowned for its efficient and stable control systems.

Pros: The ControlLogix and CompactLogix series offer exceptional scalability and data processing power, making them perfect for integrating complex SCADA systems. Rockwell also provides top-notch technical support and training, helping customers keep their systems running optimally. The intelligent features significantly reduce downtime and enhance productivity.

Cons: The high cost can be a challenge, especially for budget-conscious enterprises. Certain hardware modules may also require a significant investment.

Best for: heavy industries, petrochemical plants, and automotive assembly lines.

Uni Regal Corp. Ltd: Your Trusted Automation Parts Supplier

Aside from choosing the right PLC brand, having a reliable supplier is equally important. Uni Regal Corp. Ltd. is a leading global distributor of automation parts, offering a comprehensive range of Mitsubishi, Siemens, and Allen-Bradley products. Uni Regal is known for its extensive inventory, fast delivery, and expert technical support, making it ideal for companies needing efficient procurement and tailored automation solutions. Whether it’s responsive service or customized support, Uni Regal is committed to simplifying your procurement process and ensuring seamless project implementation.

Schneider Electric

Schneider Electric’s Modicon PLC series has a long-standing reputation in industrial automation, known for its modular design and energy-efficient features.

Pros: Schneider PLCs provide flexible network integration options and support multiple communication protocols, ideal for facilities requiring real-time monitoring and remote access. Modicon systems focus on high performance, and their modular structure simplifies system expansion and maintenance.

Cons: The complex configuration may require additional time for learning, especially for engineers unfamiliar with Schneider systems. Custom programming may also be needed for specific applications.

Best For: Building management systems, energy management, and water treatment plants.

Omron

Omron is known for its advanced control technologies and efficient automation solutions, widely used in the medical and automotive industries.

Pros: Omron PLCs, such as the NX and CP series, are recognized for their high speed and precision, making them excellent for fast-paced and precision-controlled applications. Omron has also integrated AI and IoT capabilities into its systems, making them smarter and more efficient.

Cons: The software interface is not very intuitive, which may require additional training. Some components may have supply chain limitations, impacting project timelines.

Best for: medical device manufacturing, precision assembly, and packaging industries.

ABB

ABB is a key player in power and industrial automation, known for its robust integration capabilities and global service network.

Pros: ABB PLCs have excellent interference resistance and strong processing power, making them well-suited for harsh industrial environments. The AC500 series, for instance, features modular architecture and superior communication options. ABB’s comprehensive support services also ensure reliable system operation.

Cons: Higher costs can be prohibitive for some customers, and software licensing fees may add to the total cost. Initial setup and integration may also take more time.

Best for: mining, metallurgy, and petrochemical industries.

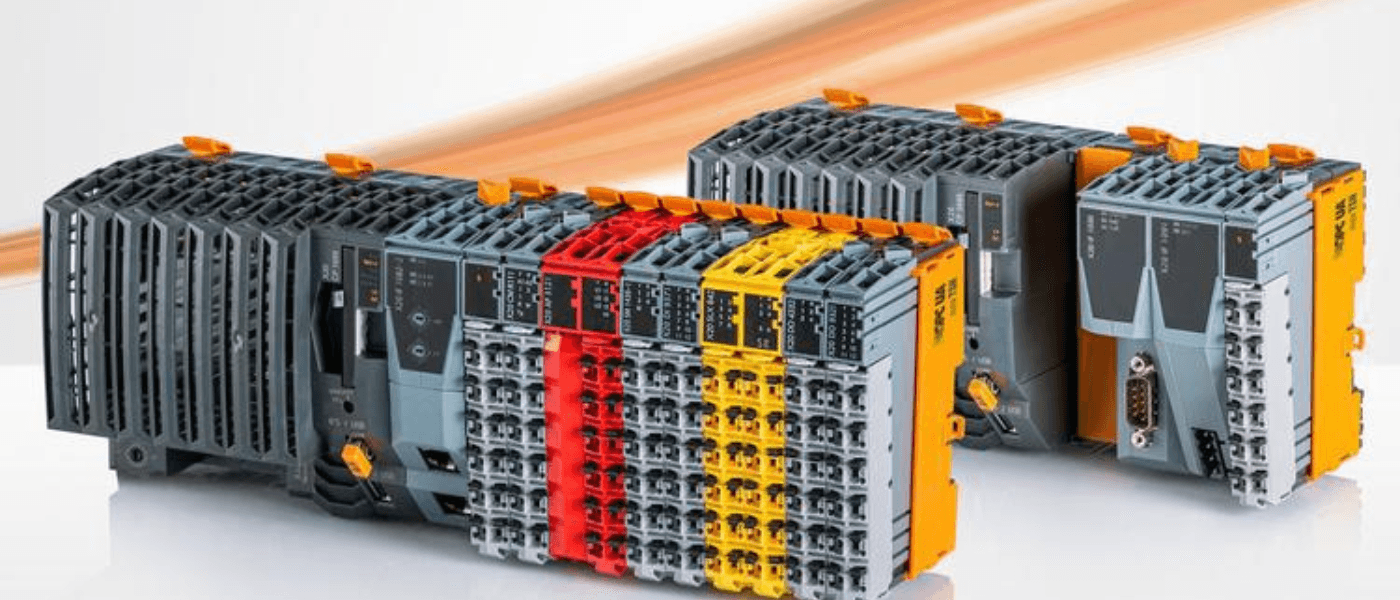

Beckhoff

Beckhoff is renowned for its innovative PC-based control technology, especially in Industry 4.0 and smart manufacturing.

Pros: Beckhoff PLCs use EtherCAT communication protocols, offering high-speed data transfer and precise real-time control. The modular design simplifies system expansion, providing great flexibility for automation engineers. The TwinCAT software platform is powerful for multitasking control applications.

Cons: Installation and programming require a high skill level, and initial configuration can be complex, especially for custom solutions.

Best For: Smart factories, robotics, and advanced manufacturing.

B&R Industrial Automation (ABB Group)

B&R Industrial Automation, now part of the ABB Group, has rapidly gained recognition for its flexible automation solutions.

Pros: B&R PLCs are known for their high performance and open architecture. The APROL software provides a comprehensive automation solution, and the Automation Studio environment simplifies complex system designs.

Cons: The brand’s market share is still relatively low, and support resources may be limited in some regions. Brand recognition may not be as strong compared to more established competitors.

Best For: Complex machinery manufacturing, packaging, and the textile industry.

FANUC

FANUC is a leader in the field of robotic control and is ideal for high-precision, high-speed industrial applications.

Pros: FANUC PLCs integrate seamlessly with their robotic systems, providing exceptional communication and coordination capabilities that maximize production efficiency. Their systems are known for their high reliability and robust performance.

Cons: FANUC PLCs are expensive, and their use outside of robotic applications is somewhat limited. Smaller companies may find the investment costs prohibitive.

Best for: automotive manufacturing, metalworking, and injection molding.

Delta Electronics

Delta Electronics focuses on cost-effective PLC solutions for a wide range of industrial automation projects.

Pros: Delta PLCs are easy to use and highly efficient, making them suitable for small and medium-sized enterprises looking to automate operations. The affordable pricing makes Delta a strong contender for budget-conscious projects. Delta also emphasizes green energy solutions, providing eco-friendly automation options.

Cons: The functionality is basic compared to high-end brands, and more complex projects may require a more advanced system. The software capabilities are somewhat limited compared to premium brands.

Best for: food processing, light industry, and building automation.

Conclusion

Each PLC brand has its own unique advantages and ideal applications. Choosing the right one depends on your project requirements and budget. We hope this detailed list gives you valuable insights for your procurement decisions. Additionally, having a reliable supplier like Uni Regal Corp. Ltd. can simplify the purchasing process and support the seamless implementation of your automation projects.