Struggling to figure out if you need an HMI or SCADA system? It's a common confusion!

The key difference lies in their scope. An HMI (Human-Machine Interface)1 is designed for local, machine-level control2, while SCADA (Supervisory Control and Data Acquisition)3 oversees entire systems or facilities from a central location. Think of it this way: HMI is for running a machine, SCADA is for managing a whole factory.

Choosing the right system is critical for efficiency. Let's break down each system, so you can confidently decide what's best for your operation.

What is HMI? (Human-Machine Interface)

What's the real meaning behind the HMI acronym? What specific role does it play in the industrial world?

An HMI (Human-Machine Interface) is a user interface that provides operators with a way to interact with machines or processes. Its primary goal is to display real-time data4 and offer control functions for localized operation and monitoring.

Imagine the control panel of a single machine. This panel shows its current status, lets you adjust settings, and alerts you to alarms. That’s the role of an HMI – it's your direct connection to that specific piece of equipment.

Definition and purpose of HMI in industrial environments

HMIs simplify complex data, presenting it in an understandable format. An operator is able to use graphs, charts, and gauges to see what’s happening right away. By doing so, they can adjust settings, start or stop operations, and respond to problems immediately.

HMI Components and Applications

| Modern HMIs consist of several key elements: | Component | Function |

|---|---|---|

| Display Unit | Shows process data | 10" resistive touchscreen |

| Control Panel | Physical buttons for operation | Emergency stop buttons |

| Communication | Links to PLCs and controllers | Modbus TCP/IP connection |

| Software | Creates visualization screens | Siemens WinCC Basic |

Common HMI applications5 include:

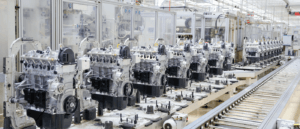

- Machine operation in automotive plants

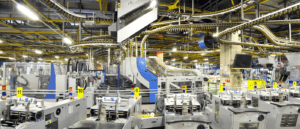

- Packaging line control

- Small-scale process monitoring

- Equipment troubleshooting

The main advantage of HMIs is their simplicity. Operators can quickly learn the interface and respond to machine conditions without extensive training. However, they lack the data collection and analysis capabilities of larger systems.

Examples of typical HMI hardware and software

HMIs can range from simple push-button panels to advanced touch screen terminals. Popular software platforms include Wonderware, Ignition, and FactoryTalk. The appropriate type of HMI is really dependent on the specific requirements of the equipment you are controlling.

Common industries and applications using HMI

You'll find HMIs in a wide variety of industries, including manufacturing, oil and gas, food and beverage, and water treatment. A lot of my customers use HMIs on their automated production lines to control machines, monitor progress, and maintain quality.

Advantages of using HMIs for localized control

The benefit of an HMI is that you can take localized control. With this, you can address issues quickly. They make it easier to train people on specific equipment. These features all improve operational efficiency.

Role of HMIs in real-time machine interaction

HMIs enable real-time interaction between operators and machines. In a manufacturing line, I like to have them to allow workers to change settings. These settings are changed in response to the issues they see in real time. The issues affect the flow or require different actions.

So that's HMI, but where does SCADA fit into the process?

What is SCADA? (Supervisory Control and Data Acquisition6)

If HMI is your machine's dashboard, what is SCADA? What scale are we talking about?

SCADA (Supervisory Control and Data Acquisition) is a control system architecture that utilizes computers, networked data communications and graphical user interfaces for high-level supervision of processes and facilities. It uses RTUs (Remote Terminal Units), PLCs (Programmable Logic Controllers), and communication networks to manage entire systems from one location.

SCADA Architecture Breakdown

A typical SCADA system contains these core components:

- Field Devices: Sensors and RTUs that gather data

- Communication Network: Transmits data to control center

- Central Server: Processes and stores information

- HMI Stations: Display system status to operators

- Historian Database: Archives historical process data

HMIs are useful, but SCADA systems are essential for enterprise-level control. They let you monitor entire factories, multiple plants, or even entire infrastructure networks. Think about complex systems from a central location!

Overview of SCADA systems and architecture

SCADA systems consist of field devices (sensors, actuators), PLCs or RTUs, communication networks, and a central SCADA server. Field devices collect data, PLCs/RTUs control machines. Data is transmitted through networks to the central server, where operators can monitor and control the entire operation.

Components: RTUs, PLCs, communication protocols7, and centralized systems

- RTUs gather data from sensors and devices in the field.

- PLCs control individual machines and processes.

- Communication protocols, like Modbus or Profibus, enable data exchange.

- Centralized systems8 provide a single point of control and monitoring.

Examples of large-scale SCADA applications

Let's imagine a city's water supply system. SCADA controls pumps, monitors water levels, and automatically adjusts water flow based on demand. I've seen similar systems that help improve operations.

Benefits of SCADA in monitoring and control across facilities

SCADA’s biggest benefits include its ability to have monitoring and control capabilities9. It enables faster decision-making and reduces downtime. SCADA systems make it possible to manage operations in real time.

Importance of SCADA in data collection and system visualization

SCADA provides real-time data visualization10. This is so important for making good decisions with the analysis and trending tools. You are able to recognize areas for improvement and optimize performance.

So we know the basics of each type of system, but now let's discuss the core differences.

Core Differences Between HMI and SCADA

What do you need to know about each if you need to choose one over the other? What factors matter most when weighing your options?

The most distinct differences are: scope (local vs centralized), data handling (simple display vs. advanced analytics), communication (device-level vs. network-level), user roles (operator vs. supervisor), and complexity/cost. HMIs offer control for machines, while SCADA provides control and analytical capabilities for larger areas.

Comparison Table: HMI vs. SCADA

| Feature | HMI | SCADA |

|---|---|---|

| Scope | Single machine/process | Multiple facilities |

| Data Handling | Real-time display only | Collection and analysis |

| User Level | Machine operators | Supervisors and management |

| Cost | $1,000-$10,000 | $50,000-$500,000+ |

| Implementation | Days to weeks | Months to years |

| Networking | Local connections | Wide-area networks |

| Customization | Limited screen designs | Full system configuration |

Scope and scale: local vs. centralized systems

HMIs operate at the machine level. SCADA systems supervise entire facilities or networks. It really boils down to whether you need to manage one machine or monitor an extensive operation.

Data handling: simple display vs. data acquisition and analytics11

HMIs display real-time data from individual machines. SCADA systems acquire and collect the same data and turn it into insights. You take this data and drive business decisions. HMIs are good if you only need to see real-time conditions.

Communication capabilities and network integration

HMIs usually connect with equipment on a local network segment. Meanwhile, SCADA systems function using a broader infrastructure. SCADA systems support many types of communication so they can operate correctly with a lot of systems.

User roles: operator vs. supervisory level control

HMIs allow operators to manage machines effectively. SCADA systems enable supervisors to monitor the total operation from a single spot. By centralizing data, you can allocate resources to improve the efficiency of daily operations.

Cost, complexity, and system implementation differences

HMIs generally are less complex, easier to deploy, and more cost-effective. SCADA systems need specialized skills for setup and maintenance. SCADA systems have higher upfront costs.

Now that we know the clear difference, let's see how the technologies function together.

How HMI and SCADA Work Together

Can you put an HMI and SCADA side by side? Do they compete, or are they designed to work together?

While distinct, HMIs and SCADA systems aren't mutually exclusive. HMIs work as components within a SCADA architecture, collecting data and providing localized control. This data flows to the SCADA. Integrated, this brings a more robust experience for users.

HMI as a component within SCADA systems

HMIs often act as the first point of contact in a SCADA structure. HMIs allow control of a single component of the wider SCADA installation. The equipment gives the data and control for individual machines.

Data flow from sensors to SCADA via HMIs

Sensors send data to the HMI, which displays the data to the local operator. Then, the HMI forwards the same data to the SCADA system. This data is now on the system for wider monitoring.

Real-world example of integrated HMI-SCADA systems12HMI-SCADA systems13

In a bottling plant, HMIs let operators control each specific filling machine. The data that is being compiled is fed to a SCADA location. The SCADA informs workers and managers about any patterns and possible issues. Managers use this data to optimize operations and reduce downtime.

How they enhance each other’s functionality

HMIs improve the SCADA function by providing local access to the equipment. A SCADA improves HMI systems by adding centralized control. Put together, the systems provide amazing management with real-time monitoring.

Decision Factors

| Requirement | Choose HMI When... | Choose SCADA When... |

|---|---|---|

| Budget | Limited funds available | Can invest in infrastructure |

| Staff Skills | Basic operator training | Have IT/engineering teams |

| Data Needs | Real-time monitoring only | Need historical analysis |

| System Size | Single machine or line | Multiple locations |

| Future Growth | No planned expansion | Expecting to scale up |

For small workshops, start with HMIs. Large facilities should implement SCADA from the beginning. Medium operations might begin with HMIs and add SCADA later as needs grow.

Use cases in smart manufacturing and Industry 4.0

Integrated HMI-SCADA systems enable improved oversight of complex equipment. Workers are now able to see predictive maintenance, and remote diagnostics are possible. Now, they have high efficiency and greatly improved performance.

How does the average business choose the right solution?

Choosing Between HMI and SCADA for Your Operation

What aspects do you have to think about when choosing one or the other for your company?

Assess the scope of your operations. Take into consideration how much data you want. Plan your budget and review each technology. Hybrid systems provide adaptability and scalability and help to protect your infrastructure for future use.

![alt text: ![choosing HMI or SCADA]](https://controllerpart.com/wp-content/uploads/2025/05/create-an-informative-and-visually-appealing-graph-1024x576.jpg)

Key factors to consider: scale, data needs, budget

- Scale: How big is the job that you are required to do? Does it require one operator or an entire staff?

- Data requirements: Do you have to trend that data out and use analytics? Do you only need basic, real-time data?

- Budget: How much do you realistically have available for the total cost?

Weigh these and your decision becomes more clear.

When HMI is enough for small-scale operations

They're the best choice when you only need hands-on control of a few devices. HMIs are a simple but effective option for basic control.

When SCADA is essential for enterprise-level control

You're in need of central control and analytics across a huge infrastructure. You have automated monitoring and want automated alerts if those criteria are outside of critical guidelines. Those require enterprise-level systems.

Hybrid systems and future-proofing your automation setup

Hybrid systems offer the ability to provide a comprehensive experience with distributed control and centralized information. The ability is future-oriented because it allows flexibility if demands grow. This strategy keeps your options open if demands change.

Tips for evaluating vendors and technology stacks

Check out vendor references. Contact current and/or former clients. Ensure that the vendor has direct experience in the sector that's the most appropriate for your situation. Checking their specs is important to ensure compatibility.

Conclusion

HMIs are critical for monitoring and operating equipment and systems. Systems and facilities are also reliable and efficient because of SCADA. The perfect system will improve your performance.

Natalie's insight: Why I Still Fight HMI vs. SCADA Battles at 2 AM

After 10 years of selling industrial controls across 12 countries, here's what keeps plant managers tossing in bed:

The HMI Reality Check

- Last month, a chocolate factory nearly melted down because their 8-year-old HMI couldn't show motor torque trends

- We replaced it with a $2,500 10-inch touchscreen - problem solved in 4 hours

- Lesson: HMIs are like good boots - cheap ones fail when you need them most

SCADA's Dirty Secret

- That shiny SCADA system? Useless without:

- Proper IT infrastructure

- Staff who understand SQL queries

- Budget for yearly license renewals

- Saw a $300k SCADA project collect dust in Vietnam because nobody could use the trending tools

My Brutally Simple Rule

- Under 15 machines? Start with robust HMIs

- Cross-shift data needed? Time for SCADA Lite

- Multiple sites? Full SCADA + pray your IT guy doesn't quit

(Pro tip: 80% of "SCADA requirements" are just fancy HMIs in disguise. Don't let vendors upsell you into oblivion.)

🔧 Need an honest assessment? Our engineers do free system audits

(Real talk: We'll tell you if you're wasting money before we sell you anything)

Understanding HMI is crucial for effective machine control. Explore this link to gain insights into its functionalities and applications. ↩

Machine-level control is essential for operational efficiency. Learn more about its significance and implementation in industries. ↩

SCADA systems are vital for managing large operations. Discover how they enhance efficiency and control in industrial settings. ↩

Discover the significance of real-time data in optimizing industrial processes and decision-making. ↩

Learn about the diverse applications of HMIs across industries and their benefits in operational control. ↩

Explore this link to gain a deeper understanding of SCADA systems and their critical role in industrial automation. ↩

Understanding communication protocols is essential for effective SCADA implementation; this link will provide valuable insights. ↩

Discover how centralized systems enhance control and monitoring in SCADA, making operations more efficient and reliable. ↩

Discover how SCADA's monitoring and control capabilities can reduce downtime and improve operational efficiency. ↩

Explore how real-time data visualization enhances decision-making and operational efficiency in SCADA systems. ↩

Learn about the critical role of data acquisition and analytics in optimizing performance and driving business decisions. ↩

Integrated systems can significantly improve operational efficiency and predictive maintenance. Learn how they transform manufacturing processes. ↩

SCADA systems are vital for centralized monitoring and control in large operations. Discover their functionalities and benefits through this resource. ↩