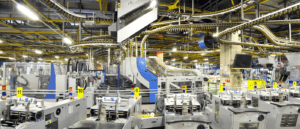

What if you could see everything happening in your factory from one place? HMIs and SCADA systems make it possible.

HMI SCADA systems1 offer real-time insights and centralized control, transforming industrial automation. Over 60% of manufacturing firms globally use SCADA to manage production lines! This guide breaks down how to harness the power of HMI and SCADA in your operations for a smarter, safer, and more scalable future.

Ready to step into the realm of HMI and SCADA? Let's walk through it together.

Understanding HMI and SCADA Systems

What are HMI and SCADA, exactly? What do they do in the world of automation?

HMI (Human Machine Interface) provides a user interface for operators to interact with machines. SCADA (Supervisory Control and Data Acquisition) oversees entire systems. HMIs focus on interaction. SCADA focuses on oversight. They both rely on components like PLCs, RTUs, and sensors to enable real-time control2 and process visibility.

HMIs are what I would call "local control panels". SCADA is sort of that "central command center." Both are invaluable in an intelligent or automated system.

Define HMI (Human Machine Interface) and SCADA (Supervisory Control and Data Acquisition)

An HMI lets operators communicate with machines. It displays data and controls. A SCADA system monitors and controls processes across an entire facility. SCADA collects data and has supervisory abilities.

Explain their individual roles in automation: HMI for interaction, SCADA for oversight

HMIs are for direct interaction. They are for operators to send commands to machines. SCADA provides oversight. They provide managers with a real-time visual of the entire operation. HMIs are useful, but a lot of customers need both pieces in systems.

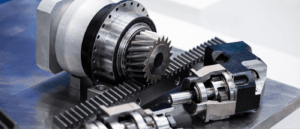

Break down core components like PLCs, RTUs, sensors, and control software

PLCs (Programmable Logic Controllers3) control machines and processes. RTUs (Remote Terminal Units) collect data from sensors. Sensors measure things like temperature and pressure. Control software manages the entire system.

Key Components

| Component | Function | Example |

|---|---|---|

| PLCs | Control individual machines | Motor control, valve actuation |

| RTUs | Remote data acquisition | Pipeline monitoring |

| Sensors | Measure process variables | Temperature, pressure, flow |

| Control Software | Manages data and operator commands | SCADA server applications |

Outline their importance in real-time control and process visibility

HMIs and SCADA let you control things in real time. This allows you to make adjustments immediately. They provide visibility into what's happening. I have seen operations that prevent problems from continuing by being alert and in real-time..

Why would I want to use both of these systems? How do they enhance operations? Let's explore HMI vs SCADA more deeply!

HMI vs SCADA: What’s the Difference?

What are the core differences that make them distinct? Under what scenarios would you choose one over the other, or both?

HMIs focus on individual machine interaction, while SCADA systems oversee larger operations. HMIs are sufficient for localized control. SCADA is required for large-scale monitoring. Using them together offers the best of both worlds!

| Feature | HMI | SCADA |

|---|---|---|

| Functionality | Direct machine interaction | Supervisory control and data acquisition |

| Scale | Local control | Centralized oversight |

| Data Handling | Simple data display | Advanced data logging and analytics |

| User Interface | Machine-level operator interface | System-wide supervisory interface |

| When to Use | Individual machine control | Large-scale monitoring and control |

| Scenarios | Controlling a single robotic arm | Managing a city's water distribution network |

| Benefits of Both | Real-time control and comprehensive data | Efficient management and operational analytics |

Let's talk more about how these systems help to enhance each other. We'll go through an example of a system.

How HMI and SCADA Work Together

Can these two systems actually function as one? What's the best way they can come together?

SCADA acts as the backend, processing data from field devices, while HMI serves as the frontend, enabling operator interaction. Using communication protocols like Modbus and OPC UA, data from SCADA is visualized on HMIs, allowing for real-time control of the combined systems.

alt text: How HMI and SCADA Work Together

Explain integration between SCADA’s backend and HMI’s frontend

SCADA's backend processes information. HMIs frontend allows the operator to interact. Communication protocols let the transfer of data from the HMI and operators to control them in the SCADA system.

Data flow from field devices to SCADA to HMI for operator interaction

Data flows to SCADA, then to HMI for operator action. Operators can monitor data and make informed operational decisions. Operators are able to have the best of both worlds between local control and widespread monitoring.

Use of communication protocols4 like Modbus, OPC UA, and MQTT

Communication protocols allow seamless integration. They define how data is exchanged. Modbus and OPC UA provide the way industrial equipment communicate without issues.

Role of data visualization and control in combined systems

Visualization displays real-time actions and control. This enables operators to take necessary steps. This is a comprehensive method for keeping a system effective.

Let's take a closer look at how these systems work together in a clear framework!

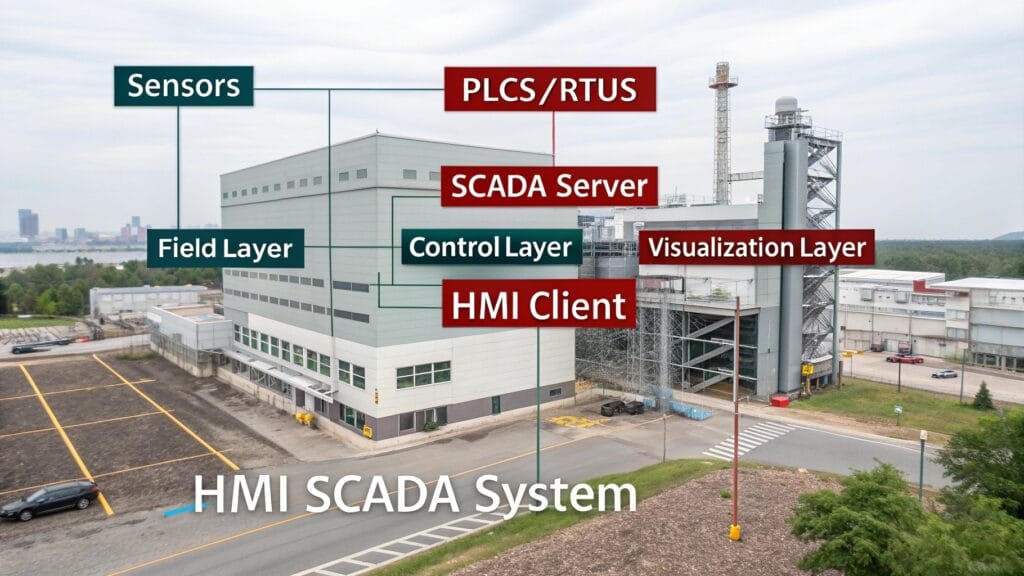

HMI SCADA Architecture Diagram

Ok, so what does it really look like when it's all put together?

A typical HMI SCADA architecture includes: sensors that collect data, PLCs/RTUs that control equipment, a SCADA server that processes data, and HMI clients for operator interaction. Communication flows through field, control, and visualization layers so that everything receives the correct information.

This can get complex fast. However, if you follow a basic framework and keep things as simple as possible, you can easily set up a fully integrated solution.

Components: sensors, PLCs, RTUs, SCADA server, HMI client

Sensors gather data. PLCs/RTUs control things in real life. SCADA severs run the system. HMI clients are what operators use. I find this setup to be amazing as long as communications run smoothly between all these components.

Layers of communication: field layer, control layer, visualization layer

The field layer is sensors and actuators. The control layer holds PLCs. Finally, visualization is HMIs and dashboards. When communications runs smoothly, the system is a force to be reckoned with.

Edge and cloud components (if applicable)

Edge computing processes data closer to the source. Cloud components provide remote monitoring. Edge and cloud parts improve system performance.

How can I get the most out of the system for my business needs? What benefits can they bring? Let's take a look!

Benefits of HMI SCADA Systems in Industrial Automation

What tangible improvements could I expect to see after putting these systems in place?

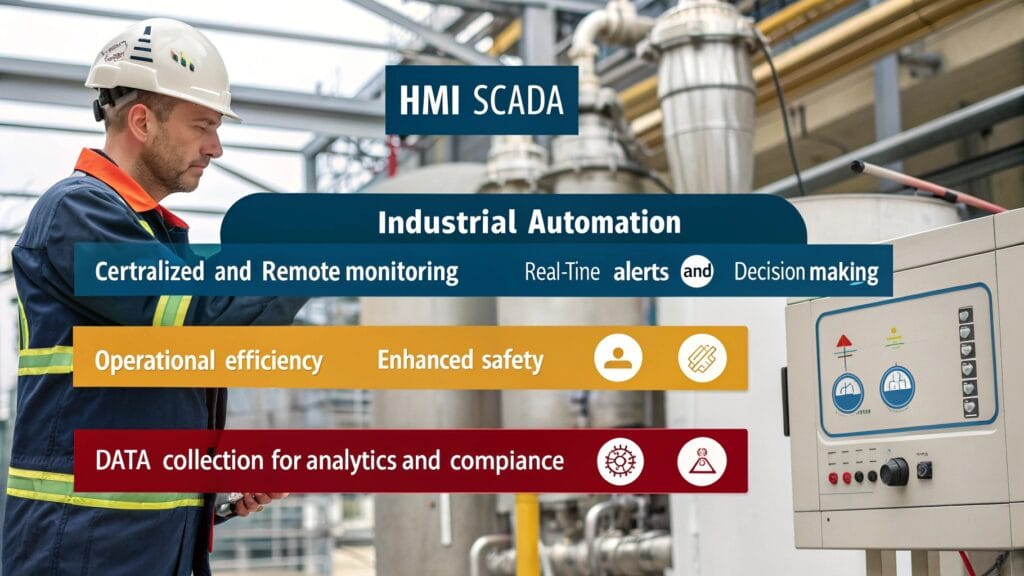

HMI SCADA systems offer centralized and remote monitoring, real-time alerts5 for quick decision-making, improved operational efficiency6, enhanced safety, and better data analytics, this provides you with a comprehensive view of industrial process to improve performance.

Centralized and remote monitoring

Operators monitor operations from one spot. Remote monitoring is able to be done at any spot if communication protocols are designed in that method. The features are very important for management.

Real-time alerts and decision-making

Alerts are in real time. Actions can be taken in the field or from a remote spot. Production numbers, costs, and safety are all improved.

Operational efficiency, reduced downtime

Process automation improves efficiency. Maintenance is scheduled because of predictive tools. Unexpected stops are kept to a minimum.

Enhanced safety through automation and diagnostics

They have automated safety controls. They have automatic diagnostics that identify any issues. HMIs and SCADA go together to create an awesome safety net.

Data collection for analytics and compliance

Data collection ensures regulatory compliance. Better data analytic capabilities are in place. Business process and performance are increased.

But what should I look for in these systems? What's critical to ensure I get the most out of them?

Key Features to Look for in HMI SCADA Systems

Are all HMI and SCADA systems created equal? What defines a top-tier solution that’s effective, user-friendly, and secure?

Look for features like intuitive dashboards, data logging, easy integration with PLCs, remote access controls, and robust cybersecurity. Also, scalability and cloud support are critical for staying competitive. These features are very important for getting a modern system that gives you efficiency and protects the system.

Intuitive and customizable HMI dashboards

You want a system that's easy to use that operators have to read. Dashboards need custom features to match their workflow. You should be comfortable and competent with it if it's well-designed.

SCADA’s data logging, trending, and alarm capabilities

Data logging1 trends help you to get insights from data. Those analytics help you enhance operations. Look for systems with those features.

Integration with existing PLCs and sensors

Check for integration with existing equipment. Systems that do that work with a lot of equipment. This allows for a system change to be seamless.

Remote access and mobile control features

Is my system scalable for future remote operations? Is your mobile workforce equipped to make things happen while in the field? The system should be ready for that.

Robust cybersecurity layers2

Cybersecurity safeguards your system against future attacks. Security protocols and constant upgrades keep the system safe. The right set of tools is very important.

Let's see them being applied!

Common HMI SCADA Use Cases and Industry Examples

How are businesses using these systems successfully today? Is it just for huge factories, or are there applications for smaller operations too?

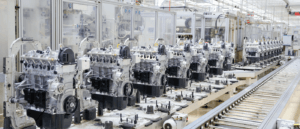

HMI SCADA systems3 are used in manufacturing for equipment control and predictive maintenance. Some other examples are, oil and gas uses them for pipeline monitoring, water uses them for quality checks. Many industries benefit by this integration.

Manufacturing: Equipment control, predictive maintenance

You can use HMIs to see data from individual machines. With SCADA, you can plan maintenance with this collected data. By having this ability to oversee your shop, you decrease issues so it increases up-time.

Oil & Gas: Pipeline monitoring, leak detection

HMIs monitor pressure to make sure that it is at the right parameters. SCADA systems can prevent breaks by finding problems. Your systems have to have a high integrity.

Water & Wastewater: Flow control, real-time quality checks

These systems make sure that water is being used correctly. With analytics from those reports, you can make sure that operations are streamlined. Having constant measurements means that you prevent poor results.

Energy: Grid monitoring, solar/wind system tracking

HMIs will help track data, and SCADA helps to see the results. You can see alerts when there are any equipment issues in the system. Having remote tracking minimizes personnel on issues.

Transportation: Intelligent traffic systems, rail control

Being able to see transportation hubs and being alert 24/7 makes HMIs and SCADA invaluable. With technology working, you can have peace of mind.

What are the top softwares can I select?

Top HMI SCADA Software & Vendors in 2025

What are the leading software options in 2025?

Leading vendors include Siemens WinCC, AVEVA/Wonderware, Ignition by Inductive Automation, GE Digital iFIX, and Schneider Electric EcoStruxure. Each offers unique features and deployment options. Before purchasing anything, do your research!

Overview of leading vendors:

- Siemens WinCC: You can monitor all operations in the facility.

- AVEVA/Wonderware: AVEVA unifies data and operations to improve overall business outcomes.

- Ignition by Inductive Automation: Ignition is an industrial software platform for HMI, SCADA, MES & IIoT.

- GE Digital iFIX: GE Digital transforms your facility with real-time data and analysis.

- Schneider Electric EcoStruxure: Schneider specializes in a suite of connected technologies.

Key features and pros/cons of each

Each software is unique. I urge you to analyze the features and cons of each provider and apply them against your business needs. You also have to make sure that the equipment integrates correctly in your system.

Deployment options: on-premise vs cloud-based SCADA

Do you want equipment in the structure or cloud-based? You should consider a cloud-based option for offsite access. Evaluate your security risks to make sure you don't have issues.

Budget considerations for small vs large enterprises

The costs depend on what scale your project will be. Costs, licensing, and equipment need to be analyzed. Ask for estimates and stay in contact with these business development managers.

Let's close out with a few last remarks.

Trends Shaping the Future of HMI SCADA Systems in 2025

Where is this tech headed? What should you watch for as you plan for the future?

The future of HMI SCADA sees a rise in IIoT and edge computing for decentralized control, cloud-based SCADA systems7 for remote access, AI for predictive checks, mobile-friendly HMIs, and an increased focus on industrial cybersecurity. I would recommend getting and staying informed about the new stuff!

Rise of IIoT and edge computing for decentralized control

IIoT (Industrial Internet of Things) is becoming a core component. Edge computing allows processing in the factory. IIoT and Edge will cause for quicker operations.

Cloud-based SCADA systems with real-time remote dashboards

Accessibility and scalability are available because of the cloud. Dashboards ensure everyone can view operations. You need to evaluate if cloud is the best option for all parameters though.

AI and machine learning in predictive analytics8 and fault detection

AI improves predictive maintenance. Fault detection gets very precise. AI can make data interpretation quicker and easier.

Mobile-friendly HMIs with AR/VR capabilities

Having remote workforces is growing. AR makes it easier for all team members. Field workers are more efficient as a result.

Increased focus on industrial cybersecurity frameworks9

Security is improved. This creates stable systems. Safety and planning are kept to a maximum.

Conclusion

HMI SCADA systems are essential tools for modern industrial automation because they offer centralized monitoring and maintenance to make decision-making safer and more scalable. Understanding the interplays between HMI and SCADA are your first steps toward safer operations. Start planning today!

Natalie's words: The Ugly Truth They Don't Tell You

"Real-time monitoring" isn't magic

- That beautiful dashboard? Worthless without:

- Proper sensor calibration (saw a temperature sensor 30°C off destroy a batch of pharmaceuticals)

- Operators trained to ACT on alarms (not just mute them)

"Centralized control" can centralize disasters

- One client's SCADA got hacked because they kept the default password "admin"

- Another lost a week's production when their "central server" was a desktop PC under someone's desk

You're Leaving Money on the Table in 2025

✔️ Edge computing - Process data locally when your WiFi inevitably drops

✔️ AI-driven alerts - Stop checking 200 tags manually every shift

✔️ Mobile dashboards - Because nobody sits at a desk anymore

The Dark Art of System Integration

Last month I watched a "top-tier" integrator:

- Spend 3 weeks trying to connect a Siemens PLC to Rockwell HMI

- Bill $28,000

- Miss that a $5 wiring fault caused the whole issue

My 3-Step Survival Guide

- Test your backup procedures (like actually unplug the server)

- Demand OPC UA support unless you enjoy vendor lock-in

- Start small - automate ONE process completely before scaling

*(Freebie: DM me "SCADA checklist" for my brutal 47-point pre-launch audit template)

🔥 Serious about optimization? Let’s pressure-test your setup - first coffee's on me.

Explore how HMI SCADA systems can revolutionize your industrial processes with real-time insights and centralized control. ↩ ↩

Discover the advantages of real-time control in automation, enhancing efficiency and responsiveness in operations. ↩ ↩

Learn about PLCs and their crucial role in automating processes, ensuring precision and reliability in operations. ↩ ↩

Exploring this resource will deepen your understanding of how communication protocols enhance SCADA systems' efficiency and reliability. ↩

This link will provide insights into the critical role of real-time alerts in enhancing operational decision-making and efficiency. ↩

Discover how operational efficiency can transform your industrial processes and lead to significant cost savings and productivity gains. ↩

Explore the advantages of cloud-based SCADA systems for remote access and scalability, crucial for modern industrial operations. ↩

Discover how AI enhances predictive maintenance and fault detection, making operations more efficient and reliable. ↩

Learn about essential cybersecurity frameworks to protect your industrial systems and ensure safe operations. ↩