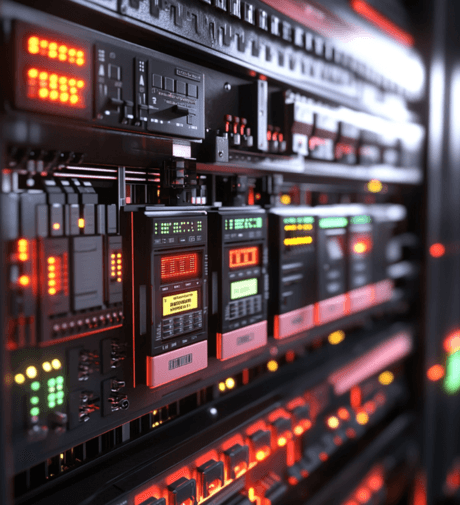

Enhance Your Automation with Allen-Bradley PLCs

Unlock the full potential of your automation systems with our customized Allen-Bradley PLC solutions. Designed to elevate your operational efficiency, these solutions offer unparalleled reliability and precision for even the most demanding industrial environments. Now is the time to take your processes to the next level. Reach out to us today to integrate Allen-Bradley PLCs into your automation strategy!

15

Years of experience

Your Go-To Partner for Allen-Bradley PLC Excellence

“Delivering Excellence with Premium Components and Customized Solutions”

Allen-Bradley PLCs are celebrated for their robust control capabilities and dependable performance. However, the complexity of industrial operations requires solutions that go beyond standard configurations. At Uni Regal Corp., we specialize in providing Allen-Bradley PLCs that are expertly configured to meet the specific demands of your industrial processes, ensuring seamless integration and optimized functionality.

Our emphasis on Allen-Bradley PLCs is driven by their flexibility and capacity to handle a broad spectrum of automation tasks with precision and reliability. Whether you need processors, input/output modules, power supplies, or communication modules, our extensive inventory caters to a wide range of industrial applications, delivering unmatched operational efficiency.

Experience the Uni Regal Corp., advantage with our customized Allen-Bradley PLC solutions, tailored to your exact specifications in functionality, scalability, and integration. Rely on our extensive industry expertise to deliver automation solutions that not only meet but exceed your expectations. Connect with us today to enhance your automation systems with our specialized, high-quality Allen-Bradley PLCs.

- Customized Solutions: We deliver Allen-Bradley PLCs tailored to the unique needs of your industrial operations, regardless of order size.

- Industry Expertise: Our team brings extensive experience and deep knowledge in industrial automation, ensuring superior guidance and support.

- Value-Driven Pricing: We offer high-quality automation products with pricing designed to maximize your budget.

- Comprehensive Inventory: Our wide selection of Allen-Bradley components ensures we can meet diverse automation requirements efficiently.

- Reliable Delivery: Our streamlined logistics process guarantees that your orders arrive on schedule, every time.

- Commitment to Quality: We prioritize excellence in both products and customer service, ensuring a smooth and trustworthy experience.

Your Reliable Partner for Allen-Bradley PLCs

Designed for efficiency and engineered to perform, our Allen-Bradley PLCs excel in the most demanding industrial environments.

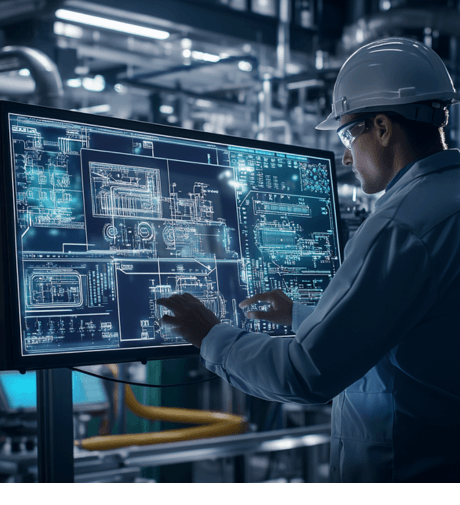

Personalize Your Allen-Bradley PLC Solutions with Uni Regal Corp.

Discover a hassle-free customization process with Uni Regal Corp. Our streamlined four-step approach guarantees you receive dedicated support throughout, overcoming typical challenges:

Step 1.

Analyzing Your Operation

Provide insights into your operation, including specific system needs, environmental factors, load capacities, overall system voltage, and critical performance benchmarks.

Step 2.

Defining Your Application

Describe the automation processes you wish to optimize, whether it’s in manufacturing control, process automation, robotics, machine safety, or another specialized field.

Step 3.

Selecting Ab PLC Components

Identify the exact components required for your system, from PLCs and I/O modules to power supplies, communication interfaces, and additional AB equipment.

Step 4

Finalizing Your Specifications

Submit your detailed requirements and quantities, ensuring that the selected components are perfectly tailored to your operational needs.

Consult with our Engineers

Your Comprehensive Guide to Acquiring Allen-Bradley PLCs

Uncover the critical impact that Allen-Bradley PLCs have on optimizing industrial automation, from streamlining manufacturing processes to managing complex control systems. Discover how these PLCs not only enhance efficiency and reliability but also offer unmatched scalability across a wide range of industrial applications.

This guide delves into the versatility of Allen-Bradley PLCs in sectors such as robotics, process automation, and machine safety, showcasing their indispensable role in ensuring seamless and robust operations. Whether you’re initiating a new automation project or considering large-scale purchases, our guide offers valuable insights to help you choose the ideal Allen-Bradley PLCs, precisely engineered to meet your specific operational demands. Additionally, learn about the long-term benefits of investing in Allen-Bradley’s advanced technology, ensuring your systems remain future-proof and resilient in an ever-evolving industrial landscape.

Table of Contents

Frequently asked questions

FAQs on Allen-Bradley PLCs

For your convenience, we’ve compiled answers to the most frequently asked questions about our Allen-Bradley PLCs. If you have additional queries, please don’t hesitate to contact us.

Allen-Bradley PLCs are programmable logic controllers used to automate industrial processes by controlling machinery and equipment. They improve efficiency, precision, and safety in various industrial applications.

Allen-Bradley PLCs are widely used across industries such as manufacturing, automotive, oil and gas, food and beverage, and utilities due to their reliability and scalability.

We provide a broad range of Allen-Bradley PLCs, including ControlLogix, CompactLogix, MicroLogix, SLC 500, and Micro800 series, each with various configurations to meet different industrial needs.

Yes, our Allen-Bradley PLCs can be tailored to your unique project requirements, ensuring optimal integration and performance for your application.

Lead times vary depending on the complexity of the customization, but we strive for efficient production and timely delivery to meet your project deadlines.

The cost varies based on the model, configuration, and any additional customization. We provide competitive pricing tailored to your specific automation needs.

The lifespan of Allen-Bradley PLCs varies based on the application and environment, but they are known for their durability and can operate efficiently for many years with proper maintenance.

The choice of PLC series impacts factors such as processing speed, memory capacity, and I/O compatibility. We can help you select the right series to match your specific operational demands.

We stand behind the quality of our products and can discuss warranty options to fit your specific needs.

Allen-Bradley PLCs support a wide range of communication protocols, including EtherNet/IP, DeviceNet, ControlNet, and more, providing flexibility for various industrial network requirements.

Yes, we offer comprehensive support for the installation, programming, and maintenance of Allen-Bradley PLCs to ensure smooth implementation and operation.

Routine maintenance includes regular system checks, firmware updates, and I/O inspections to ensure the longevity and reliability of your Allen-Bradley PLCs.

Understanding Allen-Bradley PLCs

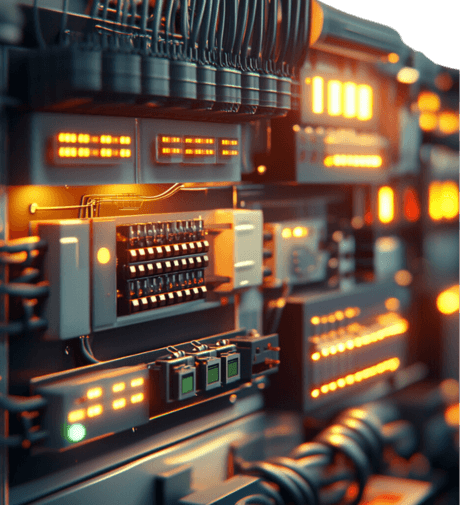

Allen-Bradley PLCs (Programmable Logic Controllers) are powerful industrial control systems engineered to automate and streamline complex processes across various industries. These controllers feature a modular design, offering exceptional flexibility and scalability to adapt to diverse industrial applications.

Renowned for their reliability, precision, and superior performance, Allen-Bradley PLCs are ideal for applications ranging from process control and machine automation to advanced robotics. Their capacity to execute demanding tasks with pinpoint accuracy and unwavering consistency makes them a cornerstone in industries where operational efficiency and precision control are critical.

These PLCs come equipped with cutting-edge features, including robust communication capabilities, a wide range of I/O configurations, and high-performance processing power. This ensures seamless integration and optimal functionality within any automation setup. For businesses focused on optimizing their production processes and achieving peak levels of automation, Allen-Bradley PLCs are an essential investment in long-term success and innovation.

Key Specifications of Allen-Bradley PLCs

Allen-Bradley PLCs are designed to excel in the demanding world of industrial automation, offering powerful specifications and cutting-edge features. Here are some key specifications:

CPU Modules

- Processing Speed: Lightning-fast speeds, up to 1 ns per instruction

- Memory: Scalable options from 50 KB to 2 MB for versatile applications

- I/O Points: Supports from 64 to 65,536 I/O points, providing flexibility for complex systems

- Communication Ports: Includes EtherNet/IP, RS-232, RS-485, and more for seamless connectivity

- Programming Languages: Supports Ladder Logic, Structured Text, Function Block Diagram, and Sequential Function Chart for versatile programming

Power Supply

- Input Voltage: Options include 24 VDC, 48 VDC, and 120-230 VAC for broad compatibility

- Power Consumption: Efficient operation with power consumption ranging from 10W to 100W

I/O Modules

- Digital Inputs: Available in 24VDC, 110VAC, and 230VAC configurations

- Digital Outputs: Choose from Relay, Transistor, and Triac options

- Analog Inputs: Supports ±10V voltage and 0-20mA current for precision control

- Analog Outputs: Provides ±10V voltage and 0-20mA current outputs

- Specialty Modules: Includes advanced options like high-speed counters, PID controllers, motion control, and safety modules

Communication

- Protocols Supported: Includes EtherNet/IP, Modbus TCP, ControlNet, and DeviceNet for versatile integration

- Network Topologies: Supports Star, Line, Ring, and Mesh configurations to suit your network architecture

Environmental Specifications

- Operating Temperature: Reliable performance from -25°C to 70°C

- Storage Temperature: Withstands extreme conditions, from -40°C to 85°C

- Humidity: Operates in environments with 5% to 95% RH (non-condensing)

- Vibration Resistance: Robust design withstanding 5 Hz to 8 Hz at 3.5 mm amplitude, and 8 Hz to 200 Hz at 9.8 m/s² acceleration

Certifications and Standards

- Certifications: Fully compliant with CE, UL, CSA, and ATEX certifications

- Standards: Adheres to industry standards including IEC 61131-2, IEC 61508, IEC 62061, and ISO 13849

These specifications ensure that Allen-Bradley PLCs provide exceptional reliability and performance across a wide array of industrial applications, making them a solid choice for businesses aiming to optimize their automation systems.

Best Practices for Safely Using Allen-Bradley PLCs

To ensure the longevity and safe operation of Allen-Bradley PLCs, it’s essential to follow proper handling and maintenance procedures. These PLCs are built with cutting-edge technology and durable construction, making adherence to safety guidelines vital for preventing damage and achieving peak performance. By implementing these practices, users can extend the lifespan of their Allen-Bradley PLCs, ensuring they remain a dependable solution for a variety of industrial applications.

- Avoid Physical Damage: Handle PLCs with care during installation and maintenance to prevent any physical harm to components, which could compromise functionality.

- Ensure Adequate Ventilation: Install PLCs in locations with sufficient airflow to prevent overheating and to maintain ideal operating temperatures.

- Protect Against Electrical Surges: Utilize surge protectors and ensure proper grounding to shield the PLC from electrical surges that could cause significant damage.

- Control Environmental Conditions: Keep PLCs away from extreme temperatures, excessive humidity, and corrosive environments that might hinder their performance.

- Maintain a Stable Power Supply: Ensure a consistent power supply to prevent fluctuations that could disrupt operations or lead to unexpected shutdowns.

- Stay Current with Firmware Updates: Regularly update the PLC’s firmware to benefit from the latest features and security enhancements.

- Perform Routine Inspections: Conduct regular inspections and preventive maintenance to identify and address potential issues before they impact system performance.

At Uni Regal Corp., we prioritize the safety, reliability, and performance of our Allen-Bradley PLCs. If you need assistance or have any questions regarding your PLCs, our team of experts is ready to provide support.

Feel free to contact us for more information about our products and how we can help meet your automation needs.

Benefits of Choosing Allen-Bradley PLCs

Allen-Bradley PLCs are renowned for their reliability, flexibility, and superior performance in industrial automation, offering numerous benefits compared to traditional control systems:

- Cost-Efficiency: Allen-Bradley PLCs deliver exceptional durability and performance, significantly reducing the need for frequent replacements and lowering overall operational costs over time.

- Scalability: These PLCs are designed with scalability in mind, allowing you to effortlessly expand your automation system as your business grows, without the need for a complete system overhaul.

- Energy Optimization: Engineered for optimal energy efficiency, Allen-Bradley PLCs help reduce power consumption, leading to more sustainable and cost-effective operations.

- Superior Performance: With rapid processing speeds and ample memory, Allen-Bradley PLCs efficiently manage complex automation tasks, ensuring reliable and consistent performance.

- Enhanced Connectivity: Allen-Bradley PLCs support a broad spectrum of communication protocols, enabling seamless integration with various systems and devices within your industrial environment.

These benefits underscore why Allen-Bradley PLCs are the preferred choice for businesses seeking dependable, efficient, and scalable automation solutions across a wide range of industries.

WIDE-RANGING APPLICATIONS OF ALLEN-BRADLEY PLCS

Allen-Bradley PLCs are highly valued for their adaptability and robust performance across multiple industries. Their durable construction and advanced technology make them indispensable in a variety of automation tasks. Here’s a look at where they truly shine:

INNOVATIVE MANUFACTURING

- Automated Production Lines: Allen-Bradley PLCs provide precise control and synchronization of automated production lines, maximizing productivity and minimizing downtime.

- Robotics Integration: Enhance the accuracy, speed, and reliability of robotic systems with Allen-Bradley PLCs, ensuring seamless integration into manufacturing processes.

- Real-Time Quality Assurance: Implement Allen-Bradley PLCs in quality control systems to monitor and adjust processes in real-time, reducing defects and ensuring product consistency.

CHEMICAL MANUFACTURING

- Batch Control: Allen-Bradley PLCs deliver precise management of batch processing, ensuring accurate control over chemical reactions and mixtures.

- Safety Systems: Monitor and manage safety protocols with Allen-Bradley PLCs, allowing for swift detection and response to hazardous conditions.

- Environmental Management: Use Allen-Bradley PLCs to maintain compliance with environmental standards by controlling emissions and managing waste processing.

ENERGY SYSTEMS

- Power Management: Efficiently manage power distribution across industrial sites with Allen-Bradley PLCs, optimizing energy use and minimizing waste.

- Renewable Energy Integration: Control and optimize the integration of renewable energy sources, such as solar and wind, into the power grid with Allen-Bradley PLCs.

- Energy Storage: Manage energy storage systems with Allen-Bradley PLCs, balancing supply and demand to maintain grid stability.

OIL AND GAS OPERATIONS

- Offshore Management: Control offshore drilling operations with Allen-Bradley PLCs, ensuring safety and efficiency in challenging environments.

- Pipeline Automation: Automate monitoring and control of oil and gas pipelines with Allen-Bradley PLCs to prevent leaks and ensure safe transportation.

- Refinery Operations: Allen-Bradley PLCs optimize refining processes by managing critical variables such as temperature, pressure, and chemical composition.

PHARMACEUTICAL MANUFACTURING

- Precise Dosing: Automate the dosing of ingredients in pharmaceutical production with Allen-Bradley PLCs, ensuring accurate and consistent formulations.

- Compliance Monitoring: Track and document production processes with Allen-Bradley PLCs to meet stringent regulatory standards.

- Cleanroom Management: Maintain sterile conditions in pharmaceutical cleanrooms with Allen-Bradley PLCs, ensuring product safety and quality.

AUTOMOTIVE PRODUCTION

- Engine Assembly: Control engine assembly lines with Allen-Bradley PLCs, ensuring precision and consistency in high-volume production.

- Automated Painting: Manage automated painting systems with Allen-Bradley PLCs, achieving uniform finishes and reducing material waste.

- Vehicle Testing: Automate vehicle testing stations with Allen-Bradley PLCs, ensuring each vehicle meets performance and safety standards before release.

WATER AND WASTEWATER TREATMENT

- Filtration Management: Control water filtration processes with Allen-Bradley PLCs, ensuring efficient removal of contaminants.

- Pump Automation: Automate pump stations with Allen-Bradley PLCs to ensure reliable water distribution and waste management.

- Chemical Dosing: Manage chemical dosing in water treatment processes with Allen-Bradley PLCs, maintaining safe and effective water quality.

FOOD AND BEVERAGE PRODUCTION

- Mixing and Blending: Allen-Bradley PLCs automate mixing and blending processes, ensuring consistency in taste and texture across production batches.

- Packaging Automation: Optimize packaging lines with Allen-Bradley PLCs, enhancing speed, accuracy, and maintaining product integrity.

- Temperature Control: Use Allen-Bradley PLCs to manage temperature regulation in food production, ensuring products meet safety and quality standards.

BUILDING AUTOMATION

- Smart HVAC Control: Optimize HVAC systems with Allen-Bradley PLCs, improving energy efficiency and maintaining comfortable indoor environments.

- Lighting Systems: Automate lighting control in buildings with Allen-Bradley PLCs, increasing energy savings and enhancing user comfort.

- Security Integration: Integrate security systems, including access control, surveillance, and alarms, with Allen-Bradley PLCs for comprehensive building security.

TRANSPORTATION INFRASTRUCTURE

- Railway Systems: Manage railway signaling and control systems with Allen-Bradley PLCs, ensuring safe and efficient train operations.

- Traffic Management: Automate traffic light control with Allen-Bradley PLCs to improve traffic flow and reduce congestion.

- Airport Operations: Control various airport operations, including baggage handling and passenger flow, with Allen-Bradley PLCs, ensuring smooth and secure travel experiences.

Allen-Bradley PLCs are essential in modern industrial and infrastructure applications, offering reliable, scalable, and efficient control solutions across diverse sectors. Their advanced technology makes them the preferred choice for optimizing operations and boosting productivity.

How to Select the Ideal Allen-Bradley PLC Components

Choosing the right Allen-Bradley PLC components is crucial for ensuring efficient operation, scalability, and long-term reliability. Here’s a comprehensive guide to help you make an informed decision:

1. Identify Your Operational Needs

- Application Scope: Clearly define the scope of your automation tasks, whether it’s for process control, discrete manufacturing, or hybrid systems.

- I/O Requirements: Evaluate the necessary input/output capabilities, considering both digital and analog needs, to match your system’s complexity and scale.

- Processing Power: Assess the processing speed and memory requirements based on the intricacy and real-time demands of your application.

2. Consider Environmental and Operational Factors

- Environmental Durability: Take into account environmental conditions such as temperature variations, humidity levels, and exposure to corrosive elements.

- Operational Endurance: Ensure the PLC components can withstand operational stresses like mechanical vibration, electrical noise, and prolonged use.

3. Choose the Right PLC Series for Your Application

- Micro800 Series: Ideal for compact, space-saving solutions where cost-effectiveness is a priority.

- CompactLogix Series: Suitable for mid-range applications requiring robust processing power and advanced diagnostics.

- ControlLogix Series: Best for high-performance applications that demand extensive processing capabilities and modular flexibility.

4. Assess Networking and Communication Needs

- Protocol Compatibility: Ensure the PLC supports key communication protocols like EtherNet/IP, DeviceNet, or Modbus for seamless system integration.

- Data Handling: For applications requiring extensive data management, opt for PLCs with high-speed communication options and cloud connectivity for Industry 4.0 initiatives.

5. Evaluate Programming Flexibility and Integration Capabilities

- Programming Standards: Verify that the PLC supports standardized programming languages such as those under IEC 61131-3 (Ladder Logic, Structured Text, etc.).

- System Compatibility: Ensure the PLC can seamlessly integrate with your existing automation systems, including older equipment, SCADA systems, and third-party devices.

6. Focus on Safety and Compliance

- Safety Certifications: Make sure the PLC components meet international safety standards (such as SIL, PL) and are certified for your specific industry.

- Built-In Safety Features: Look for PLCs with integrated safety options like fail-safe I/Os, emergency shutdown functions, and real-time fault detection.

7. Evaluate Total Cost of Ownership

- Initial vs. Long-Term Costs: Consider the long-term benefits, including energy efficiency, minimized downtime, and maintenance ease, not just the initial purchase price.

- Scalability and Future-Readiness: Choose a PLC that allows for easy expansion and upgrades, reducing future costs as your system grows.

8. Ensure Strong Vendor Support

- Technical Support: Ensure the vendor provides robust technical support, including 24/7 assistance, training sessions, and detailed product documentation.

- Warranty and Maintenance: Review the warranty coverage and check that the vendor offers comprehensive maintenance services to protect your investment over time.

By carefully considering these factors, you can select the Allen-Bradley PLC components that best suit your operational needs, ensuring a reliable, scalable, and future-proof automation system.

6. Enhanced Safety Features

- Integrated Safety Solutions: Boost machine safety by incorporating advanced safety modules, including emergency stop systems, safety interlocks, and redundant controls.

- Regulatory Compliance: Guarantee that your automation setup adheres to critical safety standards and certifications such as CE, UL, and IEC.

7. Customized User Interfaces

- HMI Personalization: Design and implement tailored Human-Machine Interface (HMI) screens that provide intuitive control and real-time monitoring of your operations.

- Security Management: Deploy configurable access controls within your HMIs, restricting system access based on user roles and authority levels.

Allen-Bradley PLCs offer the flexibility and sophisticated features required to customize your automation systems to meet your specific operational needs, ensuring enhanced efficiency, safety, and scalability.

Tailored Allen-Bradley PLC Solutions

Allen-Bradley PLCs (Programmable Logic Controllers) are celebrated for their scalability and adaptability, making them ideal for diverse industrial environments. Here’s how you can customize Allen-Bradley PLC solutions to meet your unique operational requirements:

1. Modular System Design

- Configurable Layout: Design your PLC system with a flexible modular structure, allowing you to add or remove components to precisely match your application needs.

- Scalable Expansion: Effortlessly scale your system by integrating additional I/O modules, communication ports, and more as your operational demands grow.

2. Custom Programming Capabilities

- Bespoke Logic Creation: Develop custom control logic to address the unique challenges and processes of your operation.

- Application-Specific Solutions: Implement tailored functions within the PLC to optimize specific operational workflows and enhance system efficiency.

3. Advanced Communication Options

- Seamless Network Integration: Connect Allen-Bradley PLCs to existing networks using a variety of protocols, including EtherNet/IP, DeviceNet, Modbus TCP, and more.

- Remote Access and Control: Enable remote monitoring and control of your systems, enhancing operational flexibility and improving response times.

4. Specialized Module Integration

- High-Performance Processing: Incorporate high-speed I/O modules and motion control units for applications that demand rapid data processing and precise control.

- Versatile I/O Configuration: Combine analog, digital, and specialized I/O modules to create a system tailored to the specific needs of your application.

5. Environmental Customization

- Durable Options: Select ruggedized Allen-Bradley PLC models built to withstand extreme industrial conditions, including temperature fluctuations and high humidity.

- Protective Enhancements: Opt for protective coatings to shield PLC components from environmental factors such as moisture, dust, and corrosive chemicals.

Estimated Shipping and Delivery Timeline

At Uni Regal Corp., we understand that timely delivery is crucial for our customers. As dedicated distributors of Allen-Bradley PLCs, we prioritize efficiency and speed in every step of our process to ensure your orders arrive promptly. Here’s a breakdown of our streamlined shipping and delivery process:

Our team meticulously inspects and prepares Allen-Bradley PLCs at our distribution centers. We ensure every component meets the highest standards before packing, guaranteeing top-quality products for your automation needs.

Once inspected, our staff carefully packs and boxes the Allen-Bradley PLCs. This process is swift and efficient, ensuring that your order is securely packaged for transit while minimizing the time spent in our facilities.

After packing, the products are loaded onto our transportation vehicles. Our logistics team works closely with customs to expedite clearance, allowing for a smooth transition from our distribution center to your location.

Your Allen-Bradley PLCs are then transported via the most efficient routes, whether by sea, land, or air. As soon as your shipment arrives at the destination, you will receive a notification, allowing you to arrange the final delivery or pick-up.

In summery

Allen-Bradley PLCs are highly regarded for their versatility and robust performance, making them essential in industries ranging from manufacturing to energy management.

At Uni Regal Corp., we offer a comprehensive selection of both standard and customized PLCs to meet a wide array of industrial requirements. With extensive expertise in distributing Allen-Bradley products, we provide globally trusted components, configurations, and solutions tailored to every project. Our knowledgeable team is here to assist you in choosing the perfect PLC that matches your operational needs and ensures the success of your automation projects.

Tailor Your Allen-Bradley PLC Solution

Whatever your specific needs for Allen-Bradley PLCs, our deep industry expertise ensures we can deliver the ideal solution for your operation. By working closely with trusted suppliers and leveraging our strategic sourcing capabilities, we maintain strict quality control, ensuring that our products consistently meet the highest standards. This approach also enables us to offer highly competitive pricing, giving you a distinct edge over other global distributors.