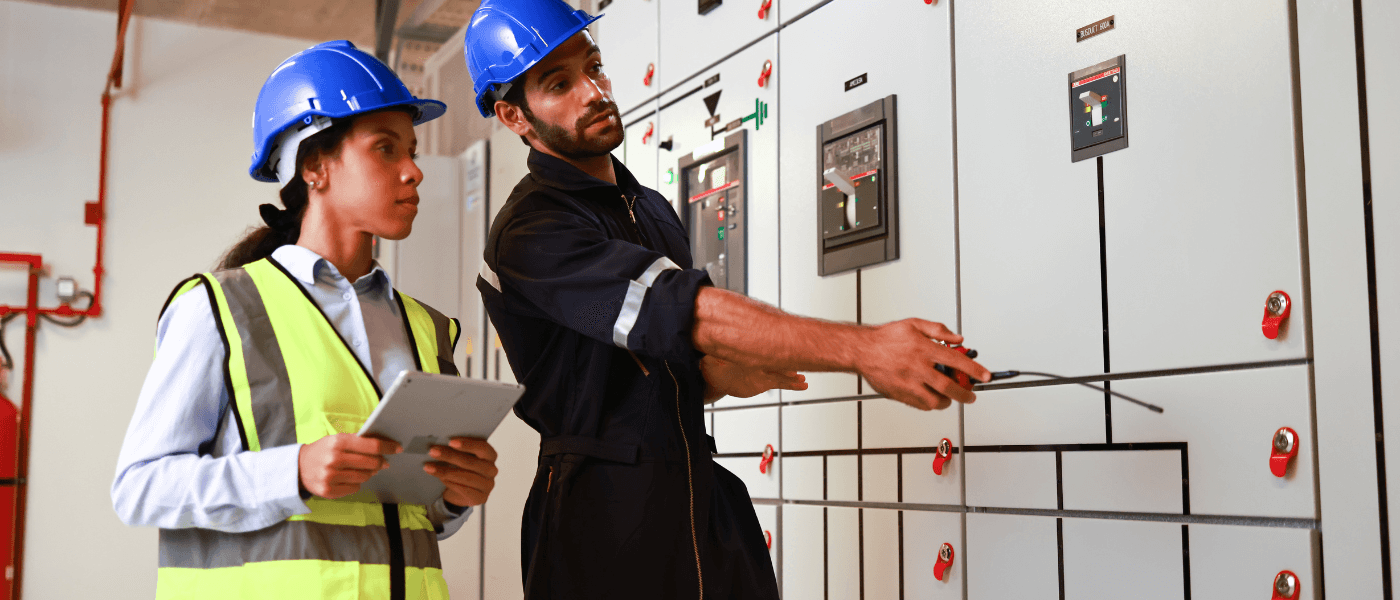

Choosing the right PLC (Programmable Logic Controller) solution provider is essential to ensure efficient and reliable automation in your industrial operations. With numerous providers on the market, each offering different PLC systems and services, the key is finding one that meets your unique business needs. Here’s a guide to help you select the right PLC solution provider who can support your automation goals and drive your production efficiency.

Start by defining your business’s automation needs and long-term objectives. A clear understanding of your requirements will make it easier to identify a provider whose expertise, services, and PLC solutions align with your goals.

What to Look for in a PLC Solution Provider

The first step is to clearly understand what you need from your PLC provider. Defining your operational requirements will help you find a reliable partner that aligns with your goals. Consider these factors:

- Price and Value

Pricing matters, but focusing solely on cost can be misleading. When evaluating a provider, consider the long-term value rather than just the initial price. While cheaper PLCs might reduce upfront expenses, they could lead to higher maintenance costs and more frequent downtime. It’s essential to balance initial costs with factors like reliability, performance, and support to ensure a good return on investment.

- Durability and Performance

Industrial environments demand PLCs built to withstand continuous use. Look for providers who offer systems made from high-quality materials designed for longevity. Durable, high-performance PLCs will ensure uninterrupted operation, reducing repair and replacement needs and improving your process efficiency.

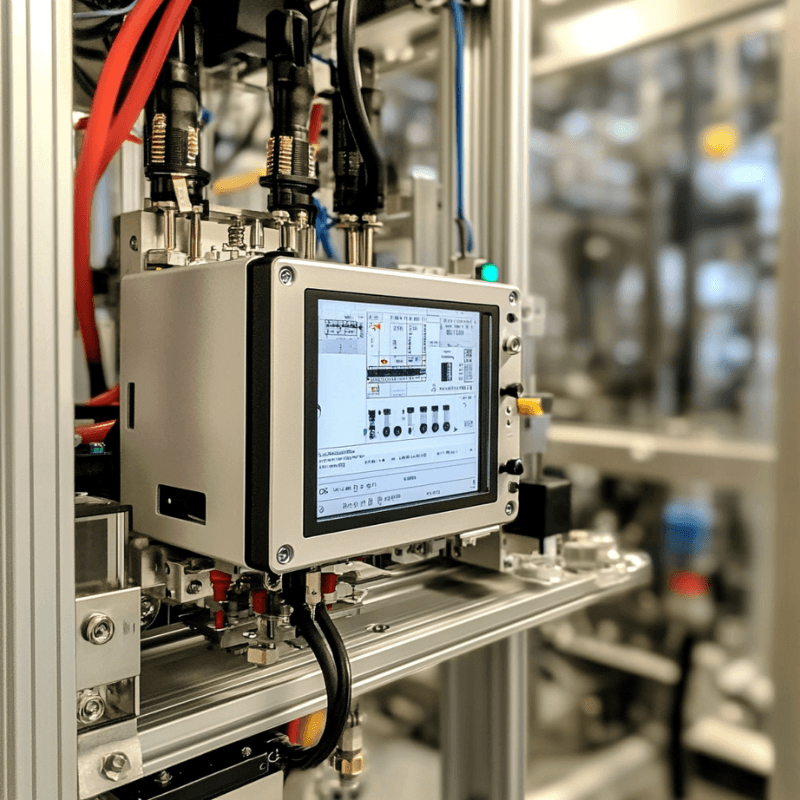

- Customization and Flexibility

Every industrial setup is unique, and your PLC solution should be as well. Providers that offer flexible, customizable PLC systems can adapt their solutions to fit your exact requirements. A good provider will assess your operations, recommend compatible systems, and ensure that the PLC integrates seamlessly with your existing equipment.

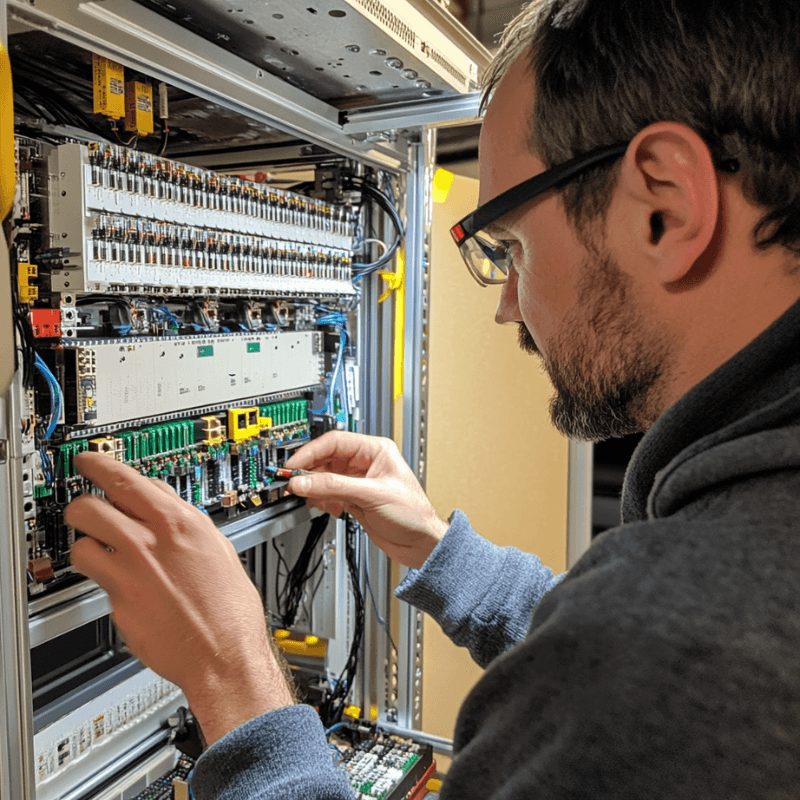

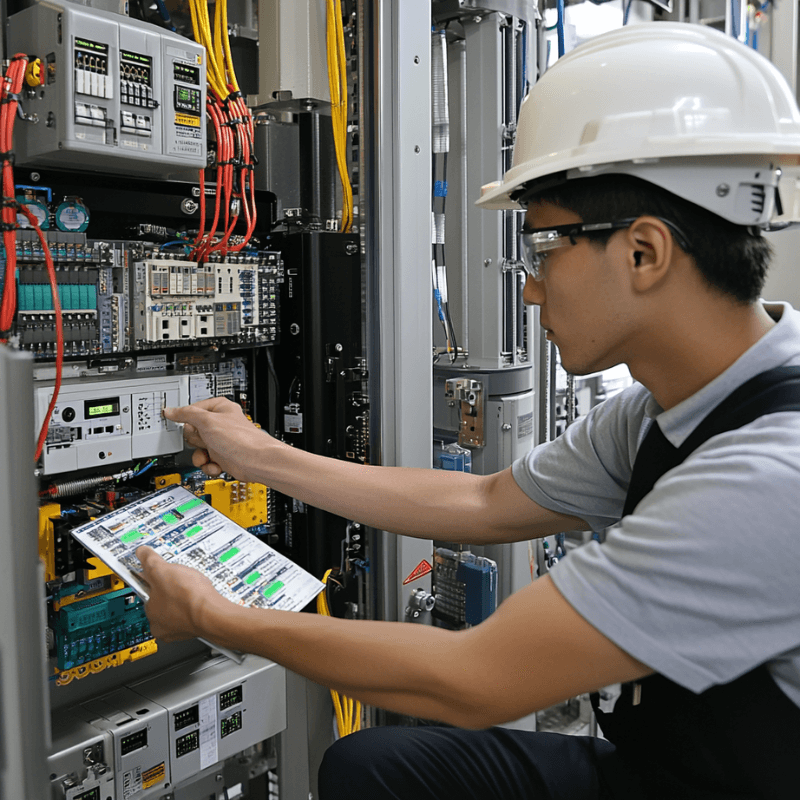

- Technical Support and Expertise

Technical support is essential to maintaining a smooth operation. Choose a provider known for responsive, reliable customer service that can support your PLC system through setup, operation, and troubleshooting. Having a knowledgeable team to rely on can reduce downtime and make adjustments easier, helping to keep your automation systems running smoothly.

- Brand Reputation and Product Range

A provider’s reputation reflects their reliability. Look for providers that work with reputable brands like Siemens, Mitsubishi, or Allen-Bradley. These brands are recognized for their reliability and performance. Also, reviewing the provider’s product range ensures they offer a variety of PLC options suited to different industry needs.

How to Find the Right PLC Solution Provider

Once you have identified your needs, the next step is to find the right PLC solution provider for your business. There are several methods you can use to make sure you choose the right partner:

- Reviewing Product Catalogs and Options

Check out the provider’s online catalog to get a sense of their offerings. Look for a variety of PLC types, such as compact, modular, or rack-mount PLCs, and evaluate their flexibility, processing power, and compatibility with your industry’s requirements. This comparison helps narrow down the options that fit best.

- Seeking Recommendations from Industry Contacts

Word-of-mouth recommendations from other businesses are invaluable. Peers, partners, or colleagues who have experience with specific PLC providers can provide honest insights into service quality and reliability. You can also request case studies or testimonials to learn about the provider's track record.

- Exploring Industry Resources and Trade Shows

Explore websites, blogs, or forums focused on industrial automation, as they often share expert reviews and comparisons of PLC providers. Trade shows and industry events are excellent venues for meeting providers directly, learning about their offerings, and asking specific questions about how they can meet your business’s needs.

Finding the Right PLC Type

Selecting the right PLC type is crucial for any automation project. PLCs come in various types depending on their functionality, size, and industry applications. Below are some common types of PLCs:

- Compact PLCs

Compact PLCs are ideal for smaller applications. They come with fixed input/output (I/O) modules and are best suited for simple, single-task operations. These systems are efficient for smaller machines or processes with limited automation needs.

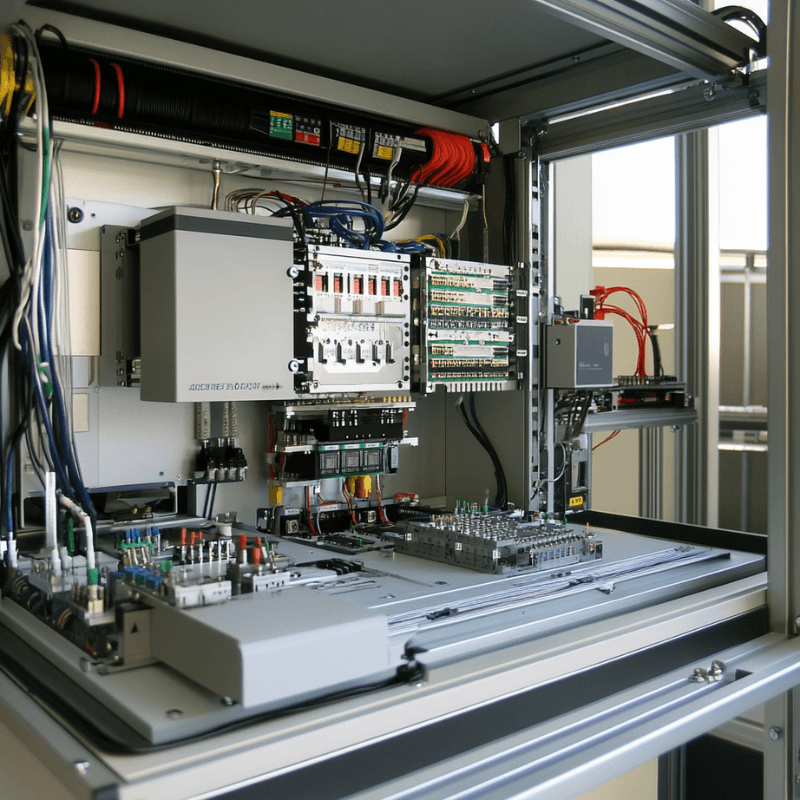

- Modular PLCs

Modular PLCs offer more flexibility with expandable I/O modules. They are ideal for larger, more complex operations that require a higher level of customization. This type of PLC allows you to add more modules as your system grows, making it a scalable solution for diverse industries.

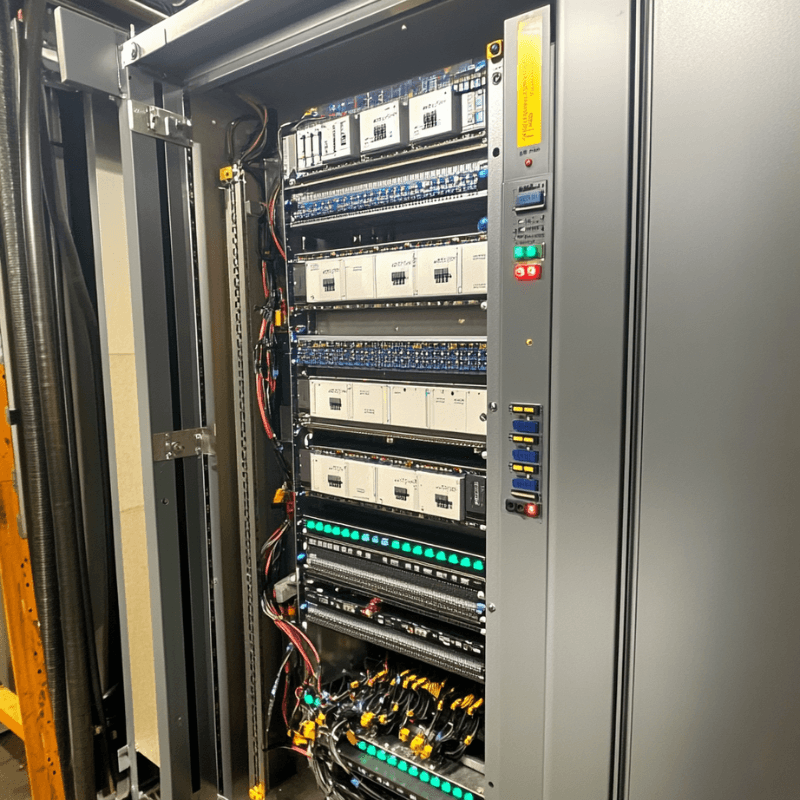

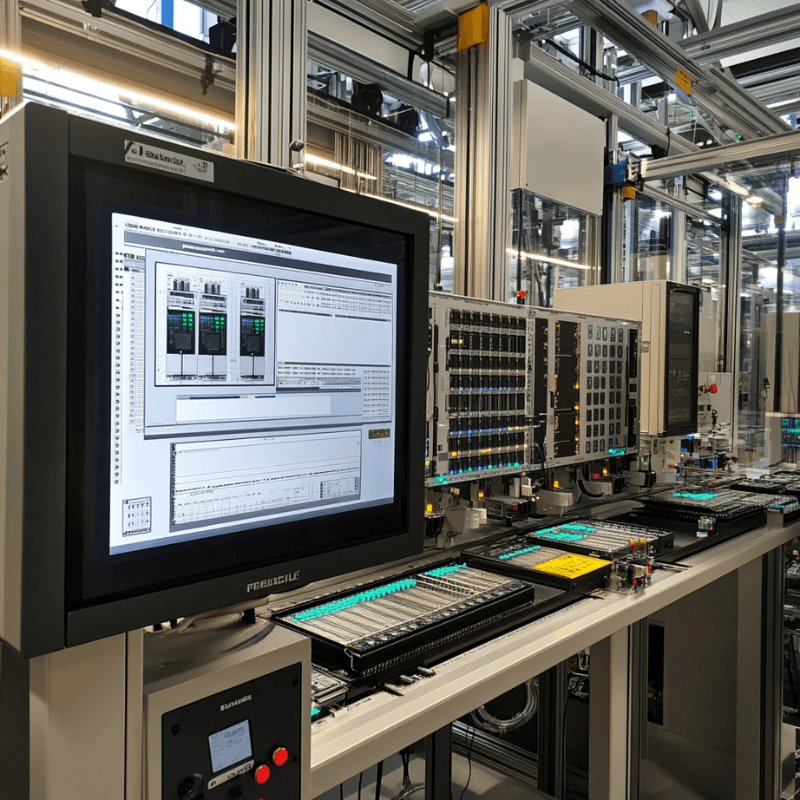

- Rack-Mount PLCs

Rack-mount PLCs are designed for large-scale industrial applications that require multiple I/O modules and high processing power. They offer maximum flexibility and control for complex automation processes in sectors like manufacturing and energy.

- Key Considerations

- Size of Operation: The more complex your processes, the larger the PLC you'll need. Consider the number of devices, sensors, and machines the PLC must control.

- Scalability: If you expect your business to grow or your automation needs to expand, choose a PLC that can scale with you, such as a modular or rack-mounted option.

- Budget: Compact PLCs are more cost-effective for smaller projects, while larger systems require more investment but offer greater flexibility and control for complex operations.

Finding the Right I/O Configuration

Choosing the right I/O modules is key to ensuring that your PLC system can handle the inputs and outputs required by your automation process. The type of I/O modules you choose will depend on the complexity and scale of your operation.

- Digital I/O: Digital modules handle on/off signals, making them ideal for basic tasks like switching devices or detecting simple conditions. They are commonly used in applications that require binary inputs or outputs, such as sensors, switches, or indicator lights.

- Analog I/O: Analog modules manage varying levels of input and output, such as temperature, pressure, or flow rates. These are essential in applications that need precise measurements or control, making them ideal for advanced industrial processes.

- Specialty I/O: Specialty modules offer advanced functionality, such as motion control or safety systems. These modules are designed for specific tasks and industries, providing additional customization and flexibility in your PLC system.

Determining the Right Configuration

When selecting the right I/O configuration, consider the following:

- Number of Devices: Estimate the number of sensors, switches, and output devices your system will control. Ensure the PLC can accommodate all current devices and any future expansions.

- Type of Signals: Identify whether your devices require digital or analog signals and choose the corresponding I/O modules. Some industries might require a mix of both.

- Flexibility: If you expect your business to grow or your processes to change, modular PLCs with expandable I/O configurations offer the flexibility to adapt without replacing the entire system.

Finding the Right Size of PLC Types

Selecting the correct size of a PLC system is crucial for ensuring that your automation processes run smoothly and efficiently. The size of the PLC you need will depend on the complexity of your operations, the number of devices you plan to control, and the scalability required for future growth.

- Small PLC Systems

Small PLC systems are ideal for businesses looking to automate simple processes or small machinery. These compact units are easy to install and provide efficient control for basic automation tasks, making them a perfect fit for industries with smaller-scale automation needs.

- Medium PLC Systems

For companies requiring more advanced control, medium-sized PLC systems offer greater flexibility and functionality. These systems can handle multiple processes, making them suitable for mid-sized operations or factories with more complex automation requirements.

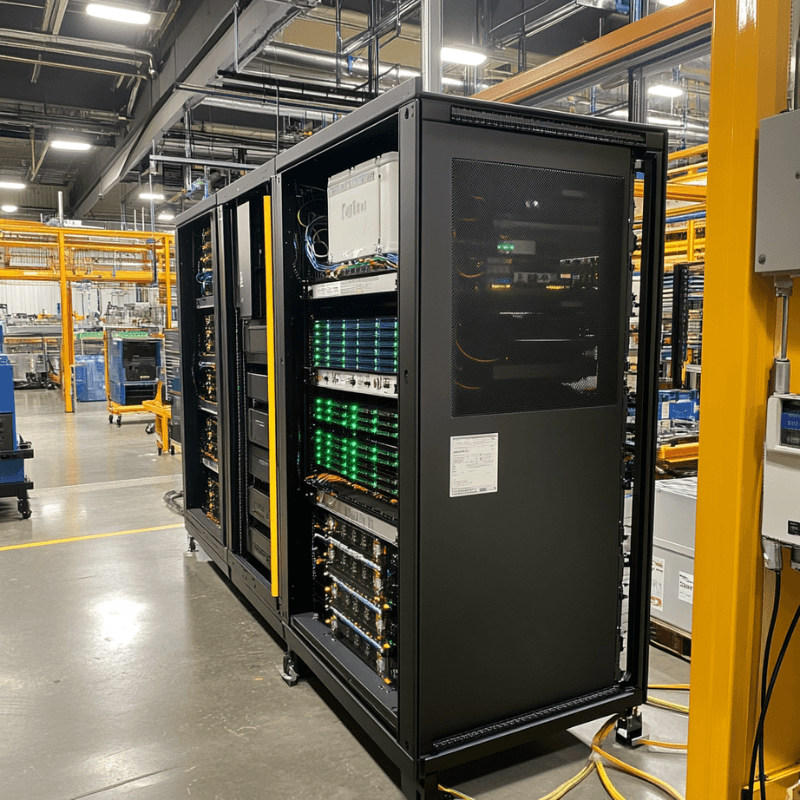

- Large PLC Systems

Large PLC systems are designed for high-level, complex automation in industries that rely on multiple processes running simultaneously. These systems can control entire production lines, providing the scalability and reliability needed for large-scale industrial automation.

Finding the Right PLCs for Your Business

Choosing the right PLC system depends on your specific operational needs. Consider the following factors when selecting the best PLC solution:

- System Compatibility

Ensure that the PLC system you choose integrates smoothly with your existing equipment and software. Seamless integration helps to avoid disruptions and ensures your automation processes run efficiently.

- Processing Speed and Memory

For businesses with more demanding automation requirements, a PLC with faster processing speed and larger memory capacity is essential. This ensures the system can handle multiple complex tasks simultaneously without delays or errors.

Selecting the Right Features for Your PLC

The right PLC system offers more than just control – it should be customizable to your business’s unique needs. Key features to consider include:

- Scalability

As your business grows, your PLC system should be able to scale up with it. Choose a solution that allows you to add more modules or expand functionality as needed, ensuring future flexibility.

- Support and Maintenance

Ensure the PLC provider offers strong technical support and maintenance services. A reliable provider will offer quick responses to issues, minimizing downtime and keeping your operations running smoothly.

Conclusion

Choosing the right PLC solution provider can transform your industrial automation processes by improving efficiency, safety, and reliability. By assessing your needs, evaluating the provider’s offerings, and selecting the appropriate PLC type and configuration, you’ll ensure your automation systems are optimized for long-term success.

Contact Uni Regal Corp., today at info@uniregal.com to discuss your PLC needs and find the perfect solution for your business.