Unleash Power with Our Industrial Inverters

Would you be ready to supercharge your operations? Uni Regal Corp.’s industrial inverters are built tough for the demands of the factory floor, delivering smooth, reliable power where you need it most. Think of our inverters as your system’s heartbeat—ensuring everything runs like clockwork, with no hiccups or downtime. We know how crucial it is to keep your machines humming, so we’ve designed our inverters for effortless integration, letting you focus on what matters: keeping your production lines moving. With UniRegal Automation, you’re not just getting a product—you’re getting a powerhouse of reliability that won’t let you down.

15

Years of experience

Your Ultimate Source for Powerful Industrial Inverters

“Streamline Your Inverter Sourcing with Trusted Expertise and Unmatched Reliability”

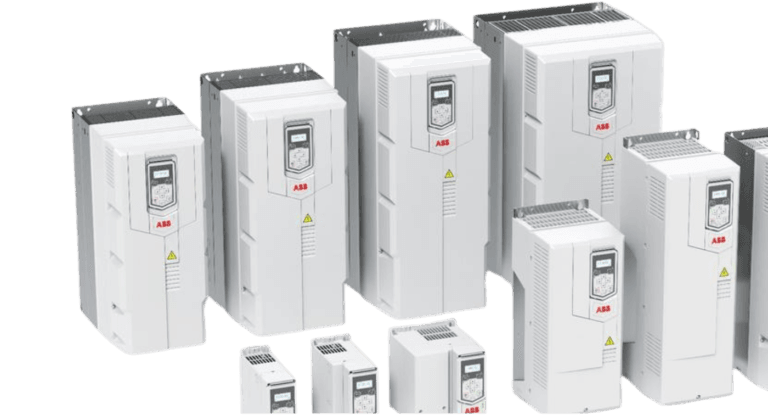

When it comes to powering your operations, you need more than just a distributor—you need a partner who truly gets the pulse of industrial automation and delivers exactly what you need, minus the headaches. At UniRegal Automation, we distribute top-tier inverters from industry giants like Mitsubishi, ABB, and Siemens, ensuring your systems get the muscle and precision they require to keep things running smoothly.

We understand the challenges—whether it’s picking the perfect inverter for a specific task, ensuring it meshes perfectly with your existing setup, or hitting tight deadlines without breaking a sweat. That’s why our team is all about making your procurement process a breeze. We provide expert insights to help you select the best inverters, backed by solid relationships with top manufacturers, guaranteeing you only receive authentic, high-quality products every time.

Our dedication doesn’t stop at just delivering products. We know how critical it is to have quick delivery, reliable stock, and support you can count on. That’s why we’ve streamlined our logistics, offering flexible options and responsive customer service to keep your operations moving like a well-oiled machine. With UniRegal Automation, you’re not just getting an inverter—you’re partnering with a team that’s as invested in your success as you are.

- Tailored Expertise: Tap into our deep industry knowledge to find the perfect inverter from top brands, precisely suited to your needs.

- Authenticity You Can Trust: We source directly from reputable manufacturers, so you always get genuine, top-notch inverters.

- Seamless Procurement: Enjoy a hassle-free buying process with our efficient logistics and flexible shipping options.

- Always Here for You: From picking the right product to post-purchase support, our team is with you every step of the way, ensuring a smooth journey.

- Vast Selection: Explore our extensive inventory of inverters, offering you the flexibility to find the perfect match for any application.

- On-Time, Every Time: We prioritize fast, reliable delivery, ensuring your inverters arrive on schedule and keep your projects on track.

Your Reliable Source for Industrial Inverters

Power your operations with inverters that excel under pressure. As your go-to distributor for brands like Mitsubishi, ABB, and Siemens, we deliver inverters that are built to handle the toughest industrial demands. Trust us for top-tier performance and reliability that keeps your productivity high and your downtime low.

Craft Your Perfect Inverter Solutions with Uni Regal Corp.,

At Uni Regal Corp., we make it easy to design inverter solutions that fit your exact needs. Our simple, four-step process keeps you in control, while we provide the know-how to turn your vision into reality.

Step 1.

Assess Your Power Demands

Kick things off by understanding your specific power needs—whether it’s managing fluctuating loads, boosting energy efficiency, or integrating with your existing setup, we’re here to listen and advise.

Step 2.

Define Your Power Goals

What’s the big picture? Whether you’re looking to enhance motor control, reduce energy costs, or optimize system uptime, map out your goals, and we’ll help you hit the target.

Step 3.

Pick Your Inverter Components

Dive into our broad selection of inverters from top brands like Mitsubishi, ABB, and Siemens. Choose the models that align perfectly with your power requirements and operational objectives.

Step 4

Finalize the deal and Power Up

Seal the deal—confirm your selections and quantities, making sure each inverter fits seamlessly into your system, ready to deliver top-tier performance right from the start.

Consult with our Engineers

Your Go-To Guide for Picking the Perfect Industrial Inverters

Ready to take your automation systems to the next level? Industrial inverters are the key to unlocking better motor control, slashing energy costs, and keeping your operations running smoothly. In this guide, we’ll dive into how inverters can be game-changers for your business, delivering the power and reliability you need across a variety of industrial applications.

We’ll walk you through the versatility of inverters—whether you’re fine-tuning manufacturing processes, managing energy loads, or upgrading your current systems. This guide is packed with practical tips and insights to help you find the inverter that ticks all the right boxes for your specific needs.

Plus, we’ll highlight the long-term perks of investing in top-notch inverter technology. Think of it as future-proofing your operations, ensuring your systems are not just efficient but also resilient and ready to tackle whatever challenges come your way in the fast-paced world of industrial automation.

Table of Contents

Frequently asked questions

Your Inverter Questions, Answered

We know that choosing the right inverter can be a big decision, so we’ve tackled some of the most common questions our clients have. Our goal is to ensure you’re fully equipped to make the best choice for your operations. If something’s on your mind that we haven’t covered, don’t hesitate to reach out.

Picking the perfect inverter isn’t just about specs—it’s about understanding your specific power needs, environmental factors, and how the inverter will fit into your existing system. We’re here to help you sort through the details and find the ideal match

We offer a selection of top brands like Mitsubishi, ABB, and Siemens, each bringing its own strengths to the table. Whether you need energy efficiency, durability in tough environments, or advanced control features, we’ll help you choose the brand that aligns with your priorities.

Worried about integration? Don’t be. Our team works with you to ensure your new inverter meshes seamlessly with your existing systems. We’ll provide expert guidance to make the transition as smooth as possible.

Installation can be tricky, but we’ve got your back. We offer support every step of the way, ensuring your inverter is up and running with minimal hassle. From setup tips to troubleshooting, we’re here to help.

We know downtime isn’t an option. That’s why we prioritize quick, reliable delivery to keep your operations on track. You’ll always be in the loop on shipping times, so there are no surprises.

Pricing varies, but we’re committed to offering competitive rates without cutting corners on quality. We’ll work with you to find the best inverter that fits your budget and meets your needs.

Absolutely. Our support doesn’t stop at the sale. Whether it’s troubleshooting a problem or offering maintenance tips, we’re here to ensure your inverter keeps performing at its best.

We offer robust warranties that reflect the quality of the inverters we provide. You can rest easy knowing your investment is protected against any potential issues.

Chances are, we’ve got a solution. Whether you’re facing tough environmental conditions, fluctuating power demands, or specific safety requirements, we’ll help you find an inverter that meets your unique needs.

Our inverters are built to last, even in the harshest conditions. With proper care, they’ll provide reliable power for years. We can recommend the best models for long-term durability and performance.

Yes, we can! We offer full support to make sure your inverters are installed and programmed correctly, fitting seamlessly into your system and meeting your operational goals.

To keep your inverters running smoothly, ensure regular cleaning to prevent dust buildup, monitor temperature levels to avoid overheating, and inspect connections periodically for wear and tear. Additionally, keep firmware updated, avoid overloading, and schedule routine professional maintenance.

What Are Industrial Inverters?

Think of industrial inverters as the heartbeat of your machinery—keeping everything running smoothly, efficiently, and right on cue. These powerful devices are the key to controlling motor speed and optimizing energy use, converting DC power into AC to meet the specific needs of your equipment. Whether you’re driving conveyor belts, powering pumps, or fine-tuning HVAC systems, inverters give you the precision and control to adapt on the fly.

Built tough for demanding environments, industrial inverters come loaded with features like overload protection, smart diagnostics, and energy-saving modes. They’re designed to keep your operations steady, even when the going gets tough, making them a go-to choice for businesses where downtime simply isn’t an option.

What’s more, inverters play nice with your existing automation setup—seamlessly integrating with PLCs, sensors, and control systems. This means you can tweak motor speeds and manage power levels right from your control panel, keeping your processes smooth and your machinery in top shape.

In a nutshell, industrial inverters are your silent partners in productivity. They cut energy costs, boost process control, and keep your operations flexible and reliable. For any industry serious about efficiency and performance, inverters aren’t just a nice-to-have—they’re essential.

Must-Have Features of Industrial Inverters

Industrial inverters are the powerhouse behind smooth, efficient operations, offering precise control and energy savings across a wide range of applications. Let’s dive into the features that make these devices a must for any serious operation:

Precision Power at Your Fingertips

- Broad Voltage Coverage: From small motors to heavy machinery, these inverters adapt to a wide range of voltages, giving you the flexibility to power just about anything.

- Smooth Operator: Say goodbye to jerky movements—advanced motor control keeps everything running seamlessly, cutting down on wear and tear.

- Quick Response: Need to adjust on the fly? Dynamic frequency control lets you adapt to shifting loads in real time, keeping your operations smooth.

- Energy Efficiency Built-In: Lower your energy bills without lifting a finger. These inverters are designed with energy-saving modes that optimize power use automatically.

Stay Connected, Stay in Control

- Plug-and-Play Connectivity: With Ethernet, Modbus, and RS-485 ports, these inverters hook up easily to your existing systems, with no hassle required.

- Protocol Agnostic: Whether it’s CANopen, Profibus, or another protocol, these inverters play nicely with all the big names, ensuring smooth integration.

- Control from Anywhere: Need to check in remotely? No problem—remote access features let you monitor and tweak performance from wherever you are.

Tailored to Your Needs

- Custom Configurations: Fine-tune settings to match your specific needs, from speed control to torque management, these inverters bend to your will.

- Built to Grow: Whether you’re running one motor or an entire fleet, these inverters scale with you, making them a perfect fit no matter the size of your operation.

- User-Friendly Interface: Setting up and adjusting your inverters is a breeze, thanks to simplified control panels and intuitive software.

Tough Enough for Any Environment

- Handles the Heat (and the Cold): Built to keep going in extreme temperatures, from cold to scorching heat, so your operations never miss a beat.

- Element-Proof: High IP ratings mean these inverters laugh in the face of dust, water, and whatever else your environment throws at them.

- Built to Last: Designed to resist constant vibrations and protect against overloads, ensuring your inverters stay in top shape, no matter the conditions.

Safety and Compliance You Can Trust

- Certified Peace of Mind: With certifications like CE, UL, and IEC, these inverters meet global safety and quality standards, so you can rest easy.

- Built-In Safety Nets: Features, like short-circuit protection, thermal monitoring, and emergency stops, ensure your operations stay secure, even when things don’t go as planned.

Future-Proof and Ready to Scale

- Modular Magic: Need to expand or upgrade? No problem—these inverters’ modular designs make it easy to scale up as your needs grow.

- Expandable I/O Options: Add more control capabilities as you go, with additional I/O modules that make these inverters as adaptable as your operations demand.

- Tech-Savvy: Packed with the latest innovations, these inverters are ready to roll with whatever the future brings, keeping your systems cutting-edge.

A User Experience That Delivers

- Easy to Use: Get up and running fast with simple setups and user-friendly interfaces that make configuration a snap.

- Instant Feedback: Stay informed with real-time diagnostics and performance alerts, so you can make quick adjustments and keep everything running smoothly.

- Quiet and Efficient: Enjoy the peace—these inverters are designed for silent operation, making your workspace more comfortable.

With these features, industrial inverters aren’t just equipment—they’re essential tools for any operation looking to maximize efficiency, ensure reliability, and stay ahead of the competition.

Best Practices for Getting the Most Out of Your Industrial Inverters

Your industrial inverters are the workhorses of your automation setup, driving efficiency and keeping things running smoothly. But to truly unlock their potential, you need to take a few proactive steps. By following these best practices, you’ll keep your inverters humming along, minimize downtime, and ensure they deliver the reliable performance your operations demand.

- Install with Care: Don’t rush the installation process. Handle your inverters with the care they deserve to avoid damaging sensitive components. A careful installation sets the stage for long-term success.

- Choose the Right Spot: Where you place your inverters matters. Keep them in areas with stable temperatures and away from dust and moisture. This not only boosts performance but also extends their lifespan.

- Lock Down Connections: Regularly check that all electrical connections are secure. Loose connections can lead to costly disruptions, so staying on top of this simple task pays off big time.

- Keep Things Cool: Inverters need to breathe, so ensure they’re well-ventilated. If your environment tends to run hot, consider extra cooling measures to keep your inverters from overheating.

- Guard Against Surges: Protect your investment by installing surge protectors and ensuring proper grounding. A power spike can do serious damage, but a little prevention goes a long way.

- Stay Current: Firmware updates aren’t just nice-to-haves—they’re essential. Keeping your inverters’ software up-to-date means you’re always benefiting from the latest features and security enhancements.

- Regular Check-Ups: Don’t wait for something to go wrong. Schedule regular maintenance to catch any issues early and keep your inverters running at their best.

At Uni Regal Corp., we understand that keeping your inverters in peak condition is crucial to your operation’s success. Our team is ready to help you maximize performance and ensure your systems run smoothly with our top-of-the-line inverters.

Reach out today and find out how we can help you achieve efficient, worry-free operations with our trusted inverter solutions.

Why Industrial Inverters ARE NEEDED?

Industrial inverters do more than just manage power—they’re the heartbeat of your operation, bringing a range of benefits that can supercharge your productivity:

- Masterful Power Control: With industrial inverters, you gain precise control over motor speeds and torque, keeping your machinery running smoothly while cutting down on energy use. This fine-tuned control not only saves money but also extends the life of your equipment.

- Instant System Feedback: Get real-time updates on your system’s performance with inverters that offer continuous monitoring. Spot potential issues before they escalate, keeping downtime to a minimum and operations on track.

- Effortless Integration: These inverters are team players, designed to seamlessly integrate with your existing automation systems. With support for multiple protocols, they ensure all your equipment works together in perfect harmony.

- Built-In Safety Nets: Equipped with features like overload protection and thermal safeguards, industrial inverters help shield your machinery from unexpected hiccups, protecting your investment and preventing costly damage.

- Tailored to Your Operation: No two operations are the same, and these inverters get that. With customizable settings, you can tweak them to fit your exact needs, whether you’re running a single motor or an entire fleet of equipment.

These advantages make industrial inverters indispensable for companies looking to optimize energy use, enhance operational efficiency, and stay ahead of the curve in a competitive landscape.

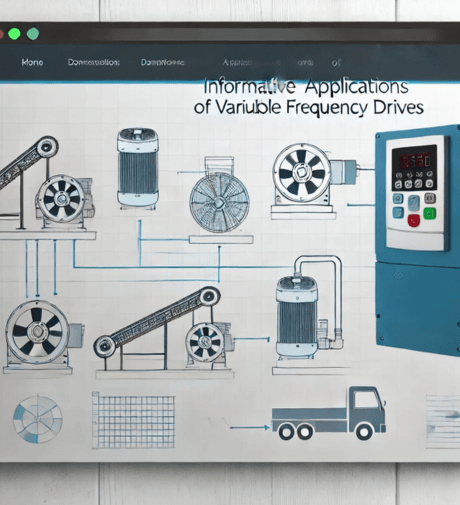

Powering Industries with Industrial Inverters

Industrial inverters are the unsung heroes behind the scenes, powering efficiency and innovation across diverse industries. By offering precise control and reliable performance, these versatile devices are crucial for businesses looking to stay competitive and keep operations running smoothly. Let’s explore how industrial inverters are reshaping industries:

Transforming Manufacturing

- Precision in Motion: Industrial inverters give you fine-tuned control over motor speeds, ensuring every piece of machinery operates with precision. The result? Faster production, less wear on equipment, and lower energy costs.

- Energy Savings on Auto-Pilot: These inverters don’t just power your machines—they optimize energy usage, helping you cut costs while keeping production lines humming.

- Minimized Downtime: With responsive performance and built-in safeguards, inverters help you avoid unexpected shutdowns, keeping your operations smooth and steady.

Revolutionizing Chemical Processing

- Spot-On Process Control: Industrial inverters offer exact control over chemical reactions, ensuring each batch is consistent, safe, and up to standard.

- Safety You Can Count On: Designed with advanced safety features, these inverters keep a watchful eye on your processes, minimizing risks and maintaining a secure work environment.

- Eco-Friendly Efficiency: By fine-tuning energy use and reducing waste, inverters help chemical plants achieve greener operations without sacrificing productivity.

Enhancing Energy Management

- Smart Power Distribution: Industrial inverters manage power flow with precision, reducing waste and ensuring a reliable energy supply across all your operations.

- Effortless Renewable Integration: Whether it’s solar, wind, or a mix, inverters seamlessly integrate renewable energy sources into your grid, making green energy work for you.

- Optimized Energy Storage: Inverters fine-tune energy storage, balancing supply and demand to keep your grid stable and efficient.

Optimizing Oil and Gas Operations

- Performance Under Pressure: Built for extreme environments, industrial inverters ensure oil and gas operations run safely and efficiently, no matter how tough the conditions.

- Pipeline Peace of Mind: Inverters provide continuous monitoring of pipeline integrity, helping to prevent leaks and ensure safe resource transport.

- Refining with Precision: These devices fine-tune refining processes, maximizing output quality and operational efficiency.

Advancing Pharmaceutical Production

- Exacting Standards: Inverters deliver the precision control needed for pharmaceutical manufacturing, ensuring every product meets strict quality requirements.

- Compliance Made Easy: With seamless data logging and process control, these inverters simplify regulatory compliance, helping you stay on the right side of the law.

- Sterile and Secure: Inverters play a key role in maintaining sterile production environments, preventing contamination, and ensuring safe, effective products.

Innovating Automotive Manufacturing

- Assembly Line Perfection: Industrial inverters keep your assembly lines moving with pinpoint accuracy, ensuring every component is in place and every vehicle is built to exacting standards.

- Flawless Finishes: Managing the complexities of painting and finishing, inverters ensure each vehicle leaves the line looking its best.

- Rigorous Testing: Before a vehicle hits the road, inverters ensure it meets all safety and performance benchmarks, leaving no detail unchecked.

Enhancing Water Management

- Efficient Pump Control: Inverters optimize water pump operations, ensuring consistent flow while reducing energy consumption and costs.

- Reliable Filtration Management: By keeping filtration systems running smoothly, inverters ensure the delivery of clean, safe water.

- Precision in Treatment: With accurate control over chemical dosing, inverters help maintain water quality that meets stringent regulatory standards.

Advancing Food and Beverage Processing

- Quality You Can Taste: Inverters are crucial in maintaining the consistency and quality of food and beverage production, ensuring every batch meets high standards.

- Speedy, Accurate Packaging: Packaging lines run faster and more precisely with inverters, ensuring products are packed efficiently and without errors.

- Temperature Control on Lock: Inverters manage temperatures with precision, ensuring food and beverages are processed and stored safely.

Revolutionizing Building Automation

- Smart Climate Control: Industrial inverters optimize HVAC systems, balancing energy use with comfort to create more efficient, sustainable buildings.

- Dynamic Lighting Control: These inverters adjust lighting based on occupancy and natural light, reducing energy consumption while maintaining the perfect ambiance.

- Integrated Security: From access control to surveillance, inverters help coordinate building security systems, ensuring a safe and secure environment.

Streamlining Transportation Infrastructure

- Rail Operations on Track: Industrial inverters manage rail systems with precision, ensuring trains run smoothly and on schedule.

- Traffic Flow Optimization: These devices help manage city traffic, reducing congestion and improving the efficiency of urban transportation networks.

- Efficient Airport Operations: Inverters streamline everything from baggage handling to passenger processing, enhancing both safety and efficiency in airport operations.

Industrial inverters aren’t just about power—they’re about empowering your entire operation. With advanced features and the flexibility to adapt to any industry, inverters are key to staying competitive, efficient, and ready for the future.

How to choose the right industrial inverters?

Picking the right industrial inverters is a critical step toward building an automation system that’s not just reliable but also future-proof. Here’s your straightforward guide to making the best choices:

1. Identify Your Power Goals

- What’s the Endgame? Begin by defining what you need—whether it’s fine-tuning motor control, slashing energy costs, or boosting your system’s reliability, having clear goals is essential.

- Voltage and Power Specs: Think about the power levels your operation demands. Are you managing a single motor, or do you need to control a more complex setup?

- Control Precision: Consider how much control you need—are you looking for simple speed regulation, or do you need advanced torque and acceleration management?

2. Match Your Environment

- Built to Withstand: Will your inverters be exposed to heat, dust, or moisture? Choose models that are built to thrive in tough industrial settings.

- Durability Matters: Ensure your inverters can handle the physical stresses of your environment, from constant vibrations to heavy daily use.

3. Choose the Right Inverter Series

- Essential Series: Perfect for straightforward applications where you need reliability without all the extras.

- Advanced Series: Ideal for more complex operations, offering better energy efficiency, robust processing, and enhanced connectivity.

- Premium Series: Designed for high-stakes environments, providing top-notch performance, extensive customization, and detailed diagnostics.

4. Prioritize Connectivity and Communication

- Protocol Friendly: Make sure your inverter supports the communication protocols you need, like Modbus, Profibus, or EtherNet/IP, for smooth system integration.

- Data-Driven: For operations where data is king, look for inverters with fast processing and cloud connectivity to keep you ahead of the curve.

5. Focus on Easy Integration

- Hassle-Free Setup: Opt for inverters that are easy to program and compatible with standard languages, so you can get up and running without a hitch.

- Plug-and-Play: Look for inverters that seamlessly fit into your existing setup, whether they’re interfacing with legacy systems, SCADA, or other devices.

6. Prioritize Safety

- Safety is Key: Your inverter should come equipped with features like overload protection, secure access, and real-time alerts to keep your operations safe.

- Meet the Standards: Ensure your inverters comply with industry-specific safety standards like CE, UL, or IP ratings, so they’re ready for your environment.

7. Think Long-Term

- Value Over Price: Don’t just look at the upfront cost—consider long-term benefits like energy efficiency, minimal downtime, and easy maintenance. Sometimes, paying a bit more initially saves you money in the long run.

- Future-Ready: Choose inverters that offer easy upgrades or expansion options, so your system can grow with your needs.

8. Demand Strong Support

- Tech Support You Can Trust: Go with a vendor that offers round-the-clock support, comprehensive training, and clear documentation to help you get the most from your inverters.

- Warranties and Service: Make sure your investment is protected with strong warranties and maintenance services from your vendor.

By following these steps, you’ll be well on your way to choosing industrial inverters that not only meet your current needs but also set you up for future success, ensuring your automation system is robust, scalable, and ready for whatever comes next.

6. Advanced Safety Features

Safety You Can Count On: Protect your operations with cutting-edge safety features like emergency stops, safety interlocks, and real-time fault detection. These features aren’t just for show—they’re your first line of defense, stepping in to keep everything secure and running smoothly, even when the unexpected happens.

Certified Peace of Mind: Rest easy knowing your inverters meet top-tier safety standards, including CE, UL, and IEC certifications. It’s not just about compliance; it’s about giving you the confidence that your systems are shielded by the best in safety practices.

7. Custom Control Interfaces

Power Your Way: Design inverter interfaces that work exactly the way you need them to. These custom controls let you make on-the-fly adjustments, ensuring your systems are always performing at their best.

Lock Down Your Controls: Set up robust security protocols within your inverters to control who can access critical settings. This keeps your systems safe from unauthorized tampering and ensures only the right people can make changes.

Industrial inverters are renowned for their versatility and cutting-edge features, making them indispensable for fine-tuning your automation systems. These capabilities ensure that your operations are efficient, secure, and ready to scale.

Customizing Industrial Inverter Solutions

Industrial inverters are designed to be as flexible as your needs, allowing you to tailor them to your specific operational demands. Here’s how you can tweak inverter solutions to perfectly match your industrial environment:

1. Modular Flexibility

Build It Your Way: Create an inverter setup that can grow and adapt with your needs. Choose a modular design that lets you add or tweak components as your system evolves—whether you’re scaling up or fine-tuning your current operations.

Room to Grow: Expand your inverter’s capabilities with additional control modules, communication interfaces, or specialized features as your operations scale, ensuring your system stays flexible and future-ready.

2. Customized Programming

Tailored Power Logic: Develop inverter programs that solve your unique challenges. Custom logic allows you to fine-tune efficiency and performance, aligning your inverters perfectly with your specific processes.

Solutions for Every Industry: Whether in manufacturing, energy management, or water treatment, program your inverters to tackle specialized tasks, streamlining operations and boosting productivity.

3. Enhanced Connectivity

Effortless Integration: Ensure your inverters connect seamlessly with your existing systems using industry-standard protocols like Modbus, Profibus, or EtherNet/IP. This guarantees smooth communication and coordination across your entire operation.

Control from Anywhere: Keep an eye on your systems from wherever you are. With remote inverter capabilities, you can make real-time adjustments, ensuring everything runs smoothly even when you’re offsite.

4. Specialized Module Integration

Precision Control at Its Finest: Integrate specialized modules that offer high-speed data processing and precise power management, keeping your systems at peak performance, even in the most complex scenarios.

Custom I/O Setup: Design an I/O configuration that perfectly matches your needs by combining analog, digital, and specialty modules, maximizing your system’s efficiency and effectiveness.

5. Built to Last

Tough Enough for Anything: Choose inverters built to handle the toughest industrial environments, from scorching temperatures to dusty, corrosive settings, ensuring they deliver consistent, reliable performance.

Shielded and Protected: Outfit your inverters with protective enclosures that guard against moisture, dust, and harsh elements, keeping them in top condition for years to come.

Comparing Top Industrial Inverter Brands: Making the Right Choice

Selecting the best industrial inverter brand is key to maximizing your automation efficiency. Here’s a comparison of four leading inverter brands, highlighting their strengths and weaknesses to help you make an informed decision:

Strengths: Mitsubishi Electric inverters are known for their top-notch reliability and cutting-edge technology. They offer superior motor control and excellent energy efficiency, making them perfect for complex automation systems. Plus, Mitsubishi provides strong support and easy system integration.

Weaknesses: These inverters come with a higher price tag, which might be a hurdle for budget-sensitive projects. Additionally, their advanced features can be more than what’s needed for simpler applications, adding unnecessary complexity.

02.

Strengths: Siemens inverters are built to last, delivering outstanding performance in the most challenging industrial environments. They support a wide array of communication protocols, ensuring smooth system integration. With a vast product range, Siemens makes it easy to find the right inverter for any application.

Weaknesses: The complexity of Siemens inverters can make installation and programming a bit daunting, especially for less experienced users. Their premium pricing might also be a drawback for smaller operations or tighter budgets.

03.

Strengths: ABB inverters are praised for their energy efficiency and intuitive interfaces. They scale easily, making them suitable for both small and large operations. With ABB’s extensive global network, support and spare parts are readily available, adding to their reliability.

Weaknesses: ABB inverters might require extra accessories to unlock their full potential, which can drive up costs. Additionally, their software can be a bit tricky to navigate for those unfamiliar with the brand.

Strengths: Schneider Electric inverters are celebrated for their durability and user-friendly design. They integrate seamlessly with existing systems and come with robust safety features. Schneider also excels in customer support and provides thorough documentation, making their products easy to use.

Weaknesses: While reliable, Schneider inverters may not offer as many advanced features as some competitors, which could be a limitation for specialized needs. They can also be more expensive in areas where Schneider has a smaller distribution network.

Final Words

Industrial inverters are the powerhouse of your operations—versatile, robust, and essential for driving efficiency in everything from cutting-edge manufacturing to smart energy management.

At Uni Regal Corp., we’re more than just a supplier—we’re your partner in powering progress. We offer a wide selection of top-notch industrial inverters, perfectly suited to meet your specific challenges. Whether you’re after trusted global brands or need a customized solution, our expertise ensures you find the right fit for your projects. Our team is here to help you navigate the options, making sure you get the best inverter to keep your systems running smoothly and efficiently, no matter what.

Simplify Your Industrial Inverter Solutions

Tired of navigating the complexities of industrial inverters? Let us streamline the process with our expert solutions. With years of industry experience, we specialize in delivering tailored inverter systems that integrate seamlessly into your operations. From sourcing to quality control, we handle everything in-house, ensuring top-tier standards at prices that keep you competitive.

Why compromise on your automation needs? Partner with us and discover industrial inverter solutions that are efficient, reliable, and designed to give you the edge you need to stay ahead in your industry.