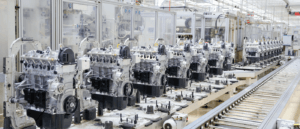

Industrial automation components are fundamental to the success of modern robotics, enabling machines to perform complex, precise, and scalable tasks across industries. These components ensure that robotics systems function seamlessly[1], efficiently, and reliably, driving innovation and productivity.

However, professionals face significant challenges in selecting the right components[2] for their robotic systems. Reliability, compatibility, cost-effectiveness, and performance are common concerns. A poor choice can lead to downtime, integration issues, or long-term inefficiencies, impacting both productivity and profitability.

The purpose of this guide is to provide actionable insights and practical strategies for sourcing the best industrial automation components[3] for robotics. Whether you are looking to upgrade existing systems or design a new setup, this blog will help you make informed decisions to achieve optimal performance and reliability.

Understanding Key Industrial Automation Components for Robotics

Controllers for Robotics Automation

Controllers are the brains of robotic systems, managing movements and processes with precision. They execute programmed instructions, synchronize components, and ensure consistent performance.

Popular Technologies:

- PLCs (Programmable Logic Controllers)[4]: Known for their robustness, PLCs are ideal for industrial settings requiring reliable and repetitive operations, such as assembly lines.

- CNC Systems (Computer Numerical Control)[5]: These systems excel in machining applications, offering high-speed and precise control for fabrication and production tasks.

Reliable controllers enable smooth operations, reducing downtime and enhancing overall productivity.

Robotics Sensors in Automation

Sensors serve as the sensory organs of robots, enabling them to perceive and interact with their environment. They are critical for tasks requiring accuracy, adaptability, and safety.

Types of Sensors:

- Vision Sensors[6]: Detect objects, analyze visual data, and guide robotic movements.

- Application: Quality inspection in manufacturing.

- Proximity Sensors[7]: Identify objects or obstacles in the robot’s vicinity.

- Application: Collision avoidance in dynamic environments.

- Force Sensors[8]: Monitor and regulate applied pressure.

- Application: Handling fragile items like electronics or glassware.

High-quality sensors enhance performance, especially in environments requiring high precision and adaptability.

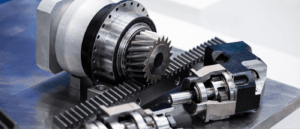

Actuators for Industrial Robotics

Actuators are the muscles of robotic systems, converting energy into motion and force. They are essential for executing physical tasks like lifting, pushing, or grasping.

| Type | Advantages | Disadvantages | Best Applications |

|---|---|---|---|

| [Electric Motors] | High precision, easy control | Limited force output | Robotic arms, small-scale tasks |

| [Servomotors] | Accurate positioning | Expensive for heavy loads | Precision movement tasks |

| [Hydraulic Actuators] | High power output | Requires complex maintenance | Heavy lifting, industrial robots |

| [Pneumatic Actuators] | Fast and lightweight | Lower precision | Quick, repetitive actions |

Choosing the right actuator depends on task-specific requirements like force, speed, and precision.

Motion Control Systems in Automation

Motion control systems synchronize the movements of robotic components, ensuring smooth and coordinated operations. These systems include a combination of controllers, servo drives, and motion software.

Key Components:

- [PLCs]: Manage centralized control of robotic actions.

- [Servo Drives]: Provide precision in multi-axis movements, essential for complex robotic tasks.

- [Integrated Motion Controllers]: Combine multiple functions to streamline processes and improve efficiency.

Motion control systems are vital for achieving high performance and accuracy in robotic operations.

End-Effectors and Connectivity Modules

End-effectors are the tools at the end of a robotic arm, enabling the robot to interact with objects or materials. Connectivity modules, on the other hand, facilitate communication and integration with broader systems.

Types of End-Effectors:

- [Grippers]: Used for picking, placing, or manipulating objects.

- [Specialized Tools]: Include welding torches, painting nozzles, or screwdrivers for specific tasks.

Connectivity Modules:

- IoT Integration Solutions[]: Enable real-time monitoring and control for predictive maintenance and data-driven decision-making.

Both end-effectors and connectivity modules are critical for enhancing the versatility and intelligence of robotic systems.

Cables and Accessories for Robotics Systems

Cables and accessories play a behind-the-scenes but crucial role in ensuring system reliability and efficiency. They provide power, data transmission, and physical support to robotics systems.

Importance:

- [Reliable cables] prevent signal loss and power interruptions.

- Accessories like [cable chains] and protective housings reduce wear and tear.

High-quality components minimize maintenance costs and downtime. Investing in robust cables and accessories ensures the long-term reliability and stability of robotics systems.

Key Considerations for Choosing Industrial Automation Components for Robotics

Reliability and Durability

The reliability and durability of industrial automation components directly impact operational efficiency. Studies show that unplanned downtime can cost manufacturers up to $260,000 per hour. High-quality parts significantly reduce the frequency of such disruptions.

Key Benefits of Durable Components:

- Extended operational life, minimizing replacement cycles.

- Improved system stability, ensuring consistent performance in demanding conditions.

For example, selecting [actuators with high wear resistance] can increase the operational life by up to 20%, saving both time and money over the system's lifecycle.

Compatibility

Ensuring seamless integration of new components with existing systems is essential for avoiding [compatibility issues] that can halt production. Reports indicate that 70% of integration failures in industrial settings stem from mismatched components.

Checklist for Compatibility:

- Match technical specifications (voltage, current, communication protocols) to the existing system.

- Confirm interoperability with control software, such as PLCs or motion controllers.

- Verify mechanical fit with existing hardware.

For instance, using a compatible controller with pre-programmed integration capabilities[^24] can reduce deployment time by 30-40%, speeding up system optimization.

Performance and Energy Efficiency

Performance and energy efficiency are often viewed as competing priorities, but advances in automation components have bridged this gap. Research indicates that modern energy-efficient components[^25] can lower power consumption by up to 25%, without compromising precision.

Why It Matters:

- Energy-efficient motors and drives reduce operational costs.

- High-performance sensors improve accuracy and reduce error rates, increasing productivity.

For example, switching to servo motors designed with low-power modes[^26] can save $3,000-$5,000 per year per robot in energy costs for large-scale facilities.

Safety and Compliance

Safety and compliance are non-negotiable for industrial automation, with regulators enforcing strict standards globally. Non-compliance can lead to fines averaging $20,000 per violation[^27] in regions like the EU and North America.

How to Ensure Compliance:

- Choose components certified to ISO 10218 or ANSI/RIA R15.06 standards[] for robotics.

- Look for safety features such as emergency stop circuits and overload protection.

Investing in compliant components not only reduces risks but also prevents costly legal complications and enhances workplace safety.

Cost vs. ROI

Balancing the upfront cost of components with their long-term benefits is crucial for sustainable operations. While lower-cost parts may seem appealing, they often lead to 30% higher maintenance expenses over five years.

Key Considerations:

- Evaluate the total cost of ownership (TCO)[^29], including installation, energy consumption, and maintenance.

- Assess ROI by calculating how performance improvements and downtime reductions offset the initial investment.

For example, premium-grade sensors[^30] may cost 30% more upfront, but their increased precision can lead to a 10% productivity boost, recouping the investment within 12 months in high-throughput environments.

By focusing on data-backed decision-making, professionals can select components that provide both immediate and long-term value.

Additional Considerations for Long-Term Optimization

Scalability

Planning for future expansion is key when selecting automation components. Systems that are scalable allow for gradual upgrades without overhauling the existing infrastructure. Research shows that scalable designs can reduce future upgrade costs by 40%.

Best Practices for Scalability:

- Opt for modular components[^31] that can be easily added or replaced.

- Ensure software platforms can accommodate new devices and functionalities over time.

- Choose equipment with surplus capacity to handle potential increases in workload.

Maintenance and Support

Reliable maintenance and manufacturer support are crucial for minimizing downtime. Studies indicate that proactive maintenance strategies can reduce unexpected equipment failures by 25-30%.

How to Choose Maintenance-Friendly Components:

- Select components with robust technical documentation and support networks[^32].

- Look for self-diagnostic capabilities to streamline troubleshooting.

- Consider components with remote monitoring options for predictive maintenance.

For example, implementing a predictive maintenance system[^33] can extend component life by identifying issues before they cause major disruptions.

Emerging Technologies

Emerging technologies like IoT-enabled sensors and AI-powered analytics are revolutionizing industrial automation. Incorporating these innovations can significantly improve system efficiency and adaptability.

How to Leverage Emerging Technologies:

- Use IoT-enabled components[^34] for real-time performance monitoring.

- Integrate AI algorithms to optimize workflows and anticipate maintenance needs.

- Explore robotics equipped with collaborative capabilities[^35] to enhance human-machine interaction in industrial settings.

By embracing these advancements, businesses can remain competitive and future-proof their operations.

Sourcing Industrial Automation Components for Robotics

Building Relationships with Automation Suppliers

Establishing strong relationships with reliable suppliers[^36] is critical for securing high-quality components and technical expertise. Surveys show that 87% of manufacturers who prioritize supplier collaboration report fewer supply chain disruptions.

Why Vendor Trust Matters:

- Suppliers with proven expertise can provide valuable guidance during component selection.

- Long-term relationships often result in better pricing, priority service, and customization options.

For example, maintaining a strategic partnership with a supplier[^37] may reduce lead times by 15-20%, ensuring faster project completion.

Evaluating Robotics Suppliers

Choosing the right supplier goes beyond price—it’s about finding a partner who understands your needs and delivers consistent quality. Reports indicate that 74% of supply chain failures result from inadequate supplier vetting[^38].

Key Evaluation Criteria:

- Certifications[^39]: ISO 9001 or ISO 14001 certifications indicate adherence to quality and environmental standards.

- Customer Reviews[^40]: Look for consistent positive feedback on reliability and support.

- Customization Capabilities: Suppliers offering tailored solutions can help meet unique project requirements.

For instance, a supplier providing bespoke end-effectors[^41] for a specialized robotic arm can enhance system functionality without requiring costly modifications.

Using Digital Tools for Sourcing Components

Digital platforms streamline the sourcing process, offering a convenient way to compare products and obtain quotes. These tools help reduce procurement times and improve decision-making.

How to Leverage Digital Tools:

- Use online catalogs[^42] to browse detailed product specifications and compatibility data.

- Access RFQ (Request for Quote) platforms to compare pricing and availability from multiple vendors.

- Utilize supplier rating systems to gauge reliability based on user feedback.

By incorporating digital sourcing tools[^43], companies can reduce procurement costs by up to 25% while ensuring they select the best components.

Ensuring Supply Chain Reliability

A reliable supply chain ensures that components are delivered on time, preventing costly delays. Research highlights that 43% of manufacturing downtime is linked to supply chain issues[^44] like stock shortages or late deliveries.

How to Strengthen Supply Chains:

- Partner with suppliers who maintain high inventory levels and offer rapid restocking.

- Opt for vendors with transparent lead time estimates and robust delivery networks.

- Monitor supplier performance[^45] regularly to identify and address potential bottlenecks.

For example, a supplier with a well-distributed logistics network[^46] can deliver components faster, even during global disruptions.

Top Suppliers for Industrial Automation Components in Robotics

Global Leaders:

- Mitsubishi Electric[^47]: Specializes in advanced motion controllers and robotic systems.

- Omron[^48]: Offers a wide range of sensors, controllers, and IoT solutions for automation.

- Siemens[^49]: Renowned for cutting-edge PLCs, servo drives, and digital twin technology.

Specialized Suppliers:

- ATI Industrial Automation[^50]: Focused on high-performance end-effectors and force/torque sensors.

- SMC Corporation[^51]: Known for pneumatic actuators and components tailored to lightweight robotic systems.

Specialized suppliers are ideal for projects requiring non-standard components or custom designs.

Tips for Choosing Reliable Suppliers

Selecting a supplier is a critical decision that impacts long-term operational success. Here’s what to look for:

- Technical Support[^52]: Ensure the supplier provides expert guidance for installation and troubleshooting.

- After-Sales Service[^53]: A robust warranty and responsive support team can save time and money during operations.

- Product Range: Suppliers with a diverse inventory can cater to multiple project needs, reducing the hassle of managing multiple vendors.

For example, a supplier offering on-site technical support[^54] can help resolve issues faster, minimizing downtime and avoiding costly delays.

Trends and Future Innovations in Robotics Automation Components

Emerging Technologies

The robotics industry is rapidly evolving with the integration of groundbreaking technologies that improve efficiency, flexibility, and adaptability.

- AI Integration[^55]: Artificial intelligence enables robots to perform complex tasks, adapt to changing environments, and learn from data.

- Example: AI-powered vision systems[^56] now achieve object recognition accuracy rates exceeding 99%, transforming quality control processes.

- Cobots (Collaborative Robots)[^57]: Designed to work alongside humans, cobots enhance productivity while maintaining safety.

- Example: Cobots can reduce labor costs by 20-30% in industries like manufacturing and logistics.

- Advanced Sensors[^58]: Innovations such as LiDAR and 3D vision sensors are enabling more precise navigation and task execution.

These technologies are redefining what robotics systems can achieve, making them more intelligent and versatile.

Sustainability

As industries focus on reducing their carbon footprint, sustainability in robotics automation components is gaining prominence.

- Eco-Friendly Designs[^59]: Manufacturers are using recyclable materials and eco-friendly production methods.

- Energy-Efficient Components[^60]: Low-power actuators and high-efficiency motors can reduce energy consumption by up to 25-30%, cutting operational costs and emissions.

Sustainable robotics not only align with environmental goals but also provide cost benefits in the long run, making them an essential consideration for forward-thinking businesses.

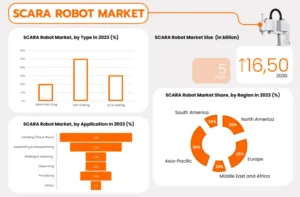

Shifting Market Dynamics

Global sourcing strategies and market demands are evolving, influenced by factors like geopolitical shifts, supply chain disruptions, and advancing technology.

- Localization of Supply Chains[^61]: Companies are moving toward local suppliers to reduce lead times and ensure reliability.

- Growing Demand[^62]: The global robotics market is projected to grow at a CAGR of 10-12% through 2030, increasing the need for reliable automation components.

- Digital Transformation[^63]: Companies are embracing digital procurement platforms for transparency and efficiency in sourcing.

Staying ahead of these trends is critical for maintaining competitiveness in the rapidly changing robotics landscape.

Conclusion

Informed decision-making is crucial for selecting the right industrial automation components for robotics. The right choices improve system reliability, efficiency, and sustainability while reducing downtime and costs.

Partnering with reliable suppliers is equally important. Trusted vendors ensure high-quality components, robust technical support, and long-term success.

eady to optimize your robotics systems with the best automation components? Explore controllerpart.com[^64] for expert advice and a comprehensive range of solutions tailored to your needs.

1.To provide readers with a deeper understanding of how automation components drive efficiency and innovation in robotics systems.

2.To address the most common challenges professionals face when choosing components and offer actionable advice.

3.To guide readers in adopting effective strategies for sourcing components, ensuring reliability and cost-effectiveness.

4.To explain the roles of PLCs and CNC systems in ensuring precise control and reducing downtime in robotics.

5.To clarify how various sensors enable robotic systems to interact effectively with their environment.

6.To provide a comprehensive comparison of actuators, aiding professionals in making task-specific choices.

7.To demonstrate how motion control systems improve synchronization, accuracy, and performance.

8.To highlight the versatility and significance of end-effectors and connectivity modules in expanding robotic functionality.

explore the latest IoT-enabled sensors and their role in real-time performance monitoring and control.