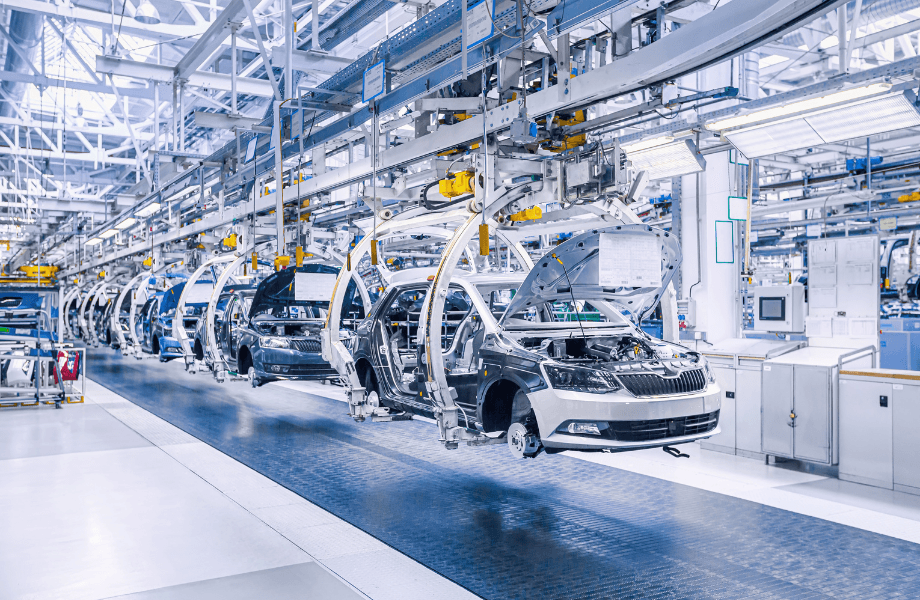

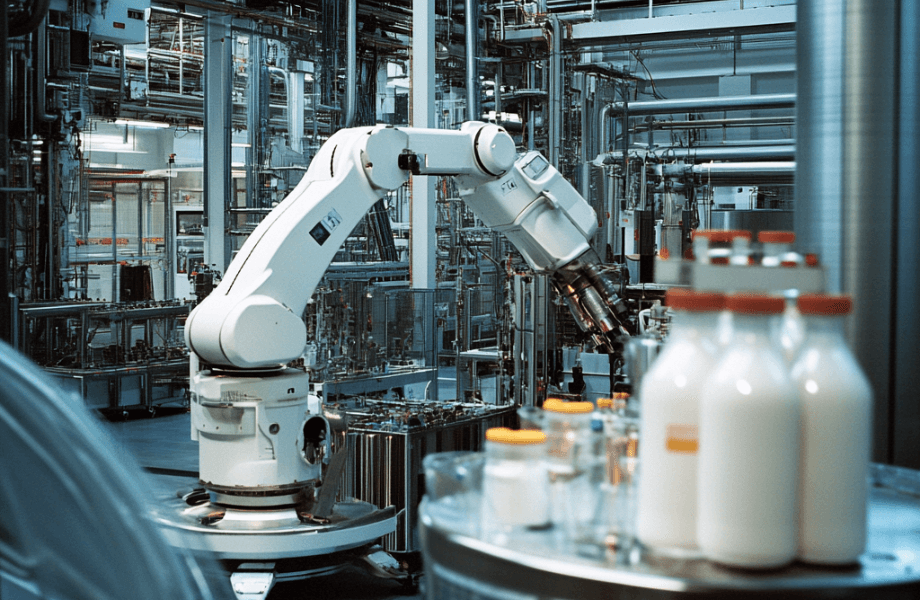

In today’s fast-paced manufacturing world, investing in industrial automation is no longer a luxury but a necessity. With the rapid advancements in automation technologies, companies that fail to adopt these innovations risk falling behind. Here are the top 5 reasons why investing in industrial automation is crucial right now.

Boost Productivity and Efficiency

Industrial automation enables companies to streamline their operations and significantly increase productivity. Automated machines work faster and more accurately than human labor, leading to higher output levels. According to a study by McKinsey, automation can boost productivity in manufacturing by 40-50%.

Example: A global electronics manufacturer increased its production speed by automating its assembly line, reducing lead times and meeting growing market demand with ease.

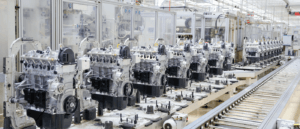

Reduce Operational Costs

One of the most compelling reasons to invest in automation is the potential for cost savings. While the initial investment may seem high, automated systems can lead to significant long-term savings by reducing labor costs, minimizing errors, and optimizing resource use. The International Federation of Robotics (IFR) reports that automated systems can lower labor expenses by up to 25%.

Example: A car manufacturing company that implemented automated welding robots saw a 20% decrease in material waste and labor costs.

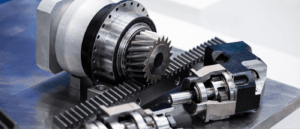

Enhance Product Quality and Consistency

Automation ensures consistent product quality by reducing the risk of human error. Machines follow precise instructions, making it easier to maintain uniform standards across all production batches. A Deloitte report found that 67% of manufacturers using automation experienced fewer defects and higher overall product quality.

Example: In the pharmaceutical industry, automated packaging lines ensure each product is packaged to exact specifications, improving quality assurance and customer satisfaction.

Improve Workplace Safety

By automating hazardous tasks, companies can create a safer work environment for their employees. Robots and automated systems can handle dangerous operations, such as heavy lifting or exposure to toxic substances, reducing the likelihood of workplace injuries. The Occupational Safety and Health Administration (OSHA) has highlighted that automation can cut workplace accidents by 30%.

Example: In chemical manufacturing, automated systems handle the mixing and transportation of hazardous materials, protecting workers from potential harm.

Stay Competitive in a Rapidly Changing Market

In today’s globalized economy, staying competitive requires embracing the latest technologies. Companies investing in industrial automation can adapt more quickly to changing market demands and trends. Automation not only allows for faster production but also provides the flexibility to scale operations up or down as needed.

Market Insight: A Boston Consulting Group study revealed that companies adopting automation technologies are 85% more likely to remain leaders in their industries.

Uni Regal Corp. Ltd: Your Trusted Partner for Industrial Automation

Implementing industrial automation requires reliable and high-quality components. Uni Regal Corp. Ltd offers a wide range of automation solutions, including PLCs, HMIs, servo motors, and more from top brands like Siemens, Mitsubishi, and Allen-Bradley. Our extensive inventory and expert technical support ensure that your automation projects run smoothly and efficiently. Partner with us to future-proof your manufacturing operations.

Conclusion

Investing in industrial automation offers unparalleled benefits, from increasing productivity and reducing costs to enhancing product quality and ensuring workplace safety. As the manufacturing landscape continues to evolve, staying ahead requires proactive investment in automation technologies. Don’t get left behind—explore how Uni Regal Corp. Ltd can help you implement cutting-edge automation solutions today.