In today’s rapidly evolving manufacturing landscape, investing in upgraded automation components is crucial for staying competitive. Outdated components can limit productivity, reduce efficiency, and increase the risk of equipment failures. Here are the top 7 benefits of upgrading your automation components and why it should be a strategic priority for your factory.

Increased Productivity and Efficiency

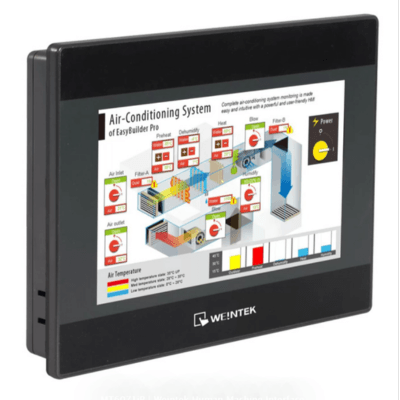

Upgraded automation components can significantly boost productivity and streamline workflows. Modern PLCs, HMIs, and servo motors are designed for faster response times and higher precision, reducing cycle times and increasing output. According to a McKinsey study, factories that invest in advanced automation experience a 30-50% increase in operational efficiency. This improvement translates to shorter production cycles and higher overall output.

Enhanced Reliability and Reduced Downtime

One of the biggest benefits of upgrading your automation components is improved system reliability. Newer components come with enhanced diagnostics and predictive maintenance features, helping you identify potential issues before they lead to costly downtime. An industry report by Deloitte found that predictive maintenance reduces unplanned downtime by up to 40%, leading to more consistent production schedules and greater overall reliability.

Better Energy Efficiency

Modern automation components are designed with energy efficiency in mind, helping factories reduce power consumption and lower operating costs. Advanced drives and energy-efficient motors can adjust power usage based on demand, minimizing waste. For example, upgrading to variable frequency drives (VFDs) has helped some factories cut energy consumption by 20–30%. This not only saves money but also contributes to a more sustainable manufacturing process.

Improved Data Collection and Analytics

Upgrading your automation components allows for better data collection and real-time analytics. Newer PLCs and sensors can gather and process data more efficiently, giving you valuable insights into machine performance and production metrics. This data can be used to optimize workflows, track equipment health, and make informed decisions. A smart factory that leverages advanced analytics can increase productivity by up to 25%, according to PwC.

Enhanced Safety Features

Modern automation components come with advanced safety features that protect both workers and machinery. Upgrades like integrated safety PLCs and smarter sensors can detect hazardous situations and automatically shut down equipment to prevent accidents. According to the Occupational Safety and Health Administration (OSHA), factories that implement advanced safety systems see a 30% reduction in workplace injuries. Safer environments also improve employee morale and productivity.

Future-Proofing Your Facility

Technology evolves rapidly, and upgrading your automation components helps future-proof your facility. Modern systems are more adaptable and can easily integrate with emerging technologies like IoT and AI. This ensures that your factory remains scalable and ready to adopt new innovations without major disruptions. Future-proofing your operations not only increases your factory's lifespan but also positions your company to take advantage of new opportunities.

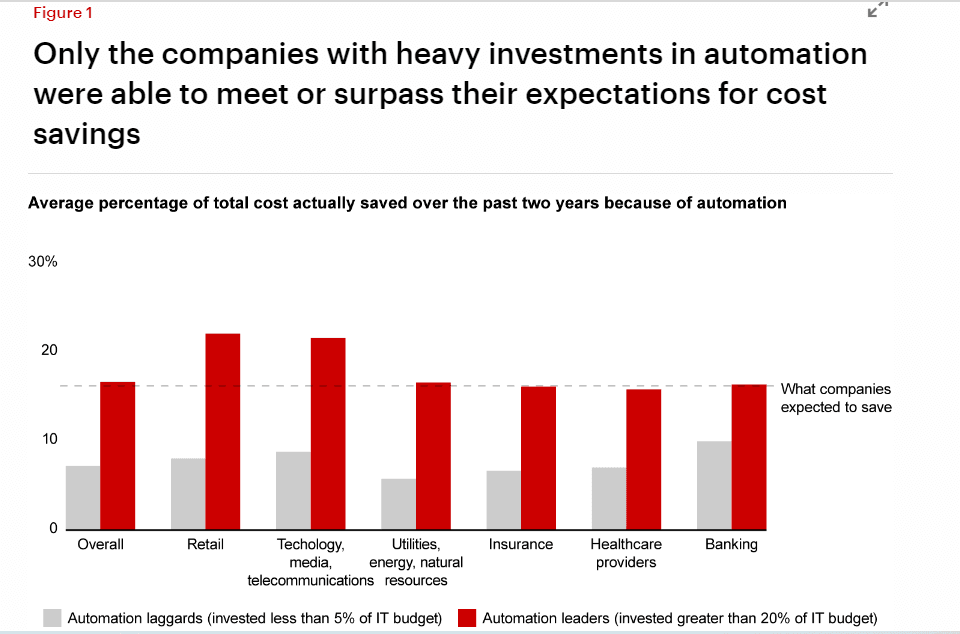

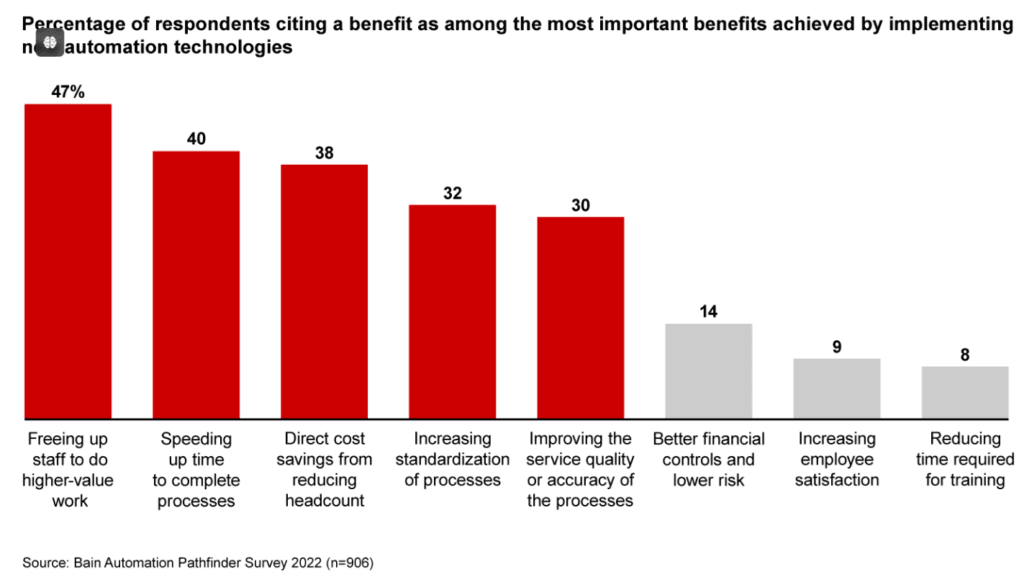

Cost Savings Over Time

While upgrading your automation components requires an upfront investment, the long-term cost savings are substantial. Reduced maintenance expenses, lower energy bills, and minimized downtime all contribute to a better return on investment (ROI). A report by Boston Consulting Group highlights that companies that invest in advanced automation technologies achieve a 15-20% reduction in overall operating costs within a few years. The savings quickly add up, making the initial expense worthwhile.

Data from Brain & Company

Uni Regal Corp. Ltd: Your Trusted Source for Automation Upgrades

When upgrading your automation components, choosing a reliable supplier is crucial. Uni Regal Corp. Ltd offers a wide range of high-quality automation parts, including PLCs, HMIs, servo motors, and sensors from top brands like Siemens, Mitsubishi, and Allen-Bradley. Our experienced team provides expert guidance to ensure you select the right components for your needs, maximizing your investment and enhancing your factory’s performance.

/

Conclusion

Upgrading your automation components is not just an option but a necessity for forward-thinking manufacturers. From increased productivity and reduced downtime to better energy efficiency and future-proofing, the benefits are clear. As your trusted partner, Uni Regal Corp. Ltd is here to help you navigate your upgrade journey and achieve long-term success in an increasingly automated world.