Are you struggling with old, hard-to-use interfaces in your plant? HMIs can seem complex, but they don't have to. Let's break it down!

An HMI, or human-machine interface1, is a system that lets operators communicate with machines and processes. It displays real-time data and allows for control, making complex systems easier to manage and understand.

If you don't understand HMIs, learning to use them can be hard. But I'm going to walk you through it.

What Is an HMI (Human-Machine Interface)?

Are you wondering what an HMI is and why it's important? Let's look at its definition, purpose, and history.

An HMI (human-machine interface) is a user interface that connects a person to a machine, system, or process. Its main purpose is to display data and provide control functions, allowing operators to monitor and manage industrial operations efficiently.

Definition and purpose of an HMI

An HMI's main job is to make it easy for people to talk to machines. It takes complicated machine data and turns it into simple visuals, like graphs and charts. This helps operators see what's happening quickly. They can also send commands to the machines through the HMI, like starting or stopping a process.

Difference between HMI and SCADA

People often mix up HMIs and SCADA (Supervisory Control and Data Acquisition) systems, but they're not the same. An HMI is usually focused on a single machine or process. SCADA systems2, on the other hand, are bigger. They control and monitor entire systems, sometimes across large areas. Think of an HMI as a local control panel and SCADA as the central command center for many panels.

Historical evolution of HMIs: From buttons to touchscreens

HMIs have come a long way. In the past, they were simple panels with buttons and lights. As technology got better, HMIs became more advanced. Now, we have touchscreens, web-based interfaces, and even mobile apps. These modern HMIs offer more data, better visuals, and remote access.

Historical Evolution of HMIs: From Simple Lights to Smart Interfaces

| Era | Interface Type | Key Characteristics | Example Applications | Limitations |

|---|---|---|---|---|

| 1960s | Indicator lights | - Basic on/off signals - Physical buttons - Hardwired controls | Factory machine control panels | No data display Limited functionality |

| 1980s | Text-based displays | - Monochrome CRT screens - Simple menus - Numeric keypads | CNC machine controls Process monitoring | Poor visualization Clunky navigation |

| 2000s | Color touchscreens | - Graphical interfaces - Multi-touch capability - Network connectivity | Automated production lines SCADA systems | Higher cost Training required |

| Today | Smart interfaces | - High-res displays - AR overlays - Cloud connectivity - AI features | Smart factories Predictive maintenance | Cybersecurity concerns Complexity |

| Future | Immersive interfaces | - Holographic controls - Voice commands - Neural interfaces | Fully automated plants Remote operations | Emerging technology High implementation cost |

Role in operator-machine communication

The role of an HMI is to act as a bridge between operators and machines. If you didn't have an HMI to turn to, an operator would struggle to understand what the machines are doing. I think of HMIs as the translator that makes it possible for people and machines to work together.

How Does an HMI Work in Industrial Automation?

How does an HMI fit into the bigger picture of industrial automation3? Is it just a fancy screen, or is there more to it?

An HMI works by connecting to PLCs (Programmable Logic Controllers), sensors, and other devices to display real-time data. It allows operators to interact with the system through input/output functions, providing control and monitoring capabilities.

An HMI is usually focused on a single machine or process. SCADA systems, on the other hand, are bigger. They control and monitor entire systems, sometimes across large areas. Think of an HMI as a local control panel and SCADA as the central command center for many panels.

Connection between PLCs, sensors, and HMIs

HMIs don't work alone. They connect to PLCs, sensors, and other devices to get data. PLCs are like the brains of the operation, controlling the machines. Sensors collect data about the process, like temperature or pressure. The HMI takes this data and shows it to the operator in a way that's easy to understand. The operator can then use the HMI to send commands back to the PLC, adjusting the process as needed.

Real-time data display and visualization

One of the best things about HMIs is that they show data in real time. This means that operators can see what's happening as it happens. They can spot problems early and fix them before they cause big issues. HMIs also use visuals like graphs and charts to make the data easier to understand.

User interaction through input/output functions

HMIs let operators interact with the system. They can use buttons, touchscreens, or keyboards to send commands to the machines. They can also see feedback from the machines on the HMI screen. This two-way communication is key to controlling and monitoring industrial processes.

Integration with control systems and field devices

HMIs need to work with other systems and devices. They need to connect to PLCs, SCADA systems, and other control systems. They also need to talk to field devices like sensors and actuators. By integrating with these systems, HMIs can provide a complete view of the industrial process. You'll have a much easier time operating industrial equipment if you have these integrations in place!

Types of HMIs Used in Industry

When it comes to HMIs, what are your options? What are the differences between basic panels and advanced software platforms?

In industry, you'll find basic push-button panels, touchscreen terminals, web-based HMIs4, and advanced HMI software platforms5. Each type serves different needs, from simple controls to complex data analysis and remote access.

| Type | Best For | Example Applications |

|---|---|---|

| Push-button panels | Harsh environments | Oil rig control stations |

| Touchscreen terminals | High-density controls | Pharmaceutical batch recording |

| Web-based HMIs | Remote monitoring | Multi-site utilities management |

| Software platforms | Complex systems | Automotive assembly SCADA |

Basic push-button panels

These are the simplest type of HMI. They have buttons, lights, and maybe a small screen. They're good for basic tasks like starting and stopping machines. I used to work in a plant where these were everywhere. Workers used them to start and stop conveyor belts. They're not fancy, but they're reliable.

Touchscreen terminals

These are more advanced than push-button panels. They have a touchscreen that lets operators interact with the system. Touchscreen terminals can show more data and offer more control options. They're easy to use and can be customized to fit different needs. I find these are great for showing a variety of real-time operational data to team members who are responsible for monitoring system performance.

Web-based and mobile-accessible HMIs

These HMIs can be accessed through a web browser or a mobile app. This means that operators can monitor and control their systems from anywhere. Web-based HMIs are great for remote monitoring. Mobile apps let operators check on things while they're on the go.

Advanced HMI software platforms (e.g., Wonderware, Ignition)

These are the most powerful HMIs. They offer a wide range of features, including real-time monitoring6, alarm management, and data analysis. Advanced HMI software platforms are used in big industrial operations where things are complex. They can handle a lot of data and offer advanced control options.

Think about which type of HMI makes the most sense for your situation. Now, let's get into the key features and functions of modern HMIs!

Key Features and Functions of Modern HMIs

What can modern HMIs really do? Let's dive into their key features and functions and see how they can transform your industrial processes.

Modern HMIs offer real-time monitoring and control7, alarm management, data logging, security features, and multi-language support. These features help operators manage complex systems, improve safety, and make informed decisions. You should think about these components when comparing one HMI to another.

Real-time monitoring and control

Modern HMIs show what's happening as it happens. Operators can see data from sensors and machines in real time. They can also use the HMI to control the machines and processes. This real-time control lets operators make quick changes to keep things running smoothly.

Alarm management and notifications

Modern HMIs can also send alarms when something goes wrong. If a temperature gets too high or a pressure gets too low, the HMI will alert the operator. This lets operators respond quickly to problems and prevent damage. The way notifications are managed in many HMIs allows alerts to be sent to various people throughout an organization depending on the type of alert (i.e. maintenance vs. safety).

Data logging and trend analysis

HMIs can record data over time. This data can be used to see how the system is performing and identify trends. Data logging and trend analysis can help operators optimize their processes and improve performance. I had a client who used an HMIs data and alarm management capabilities to anticipate when machines were most likely to have issues, allowing them to reduce downtime by scheduling maintenance during slower periods.

Security and access control features

Security is very important. Modern HMIs have security features to protect the system from unauthorized access. Operators need a username and password to log in. Different operators can have different levels of access. Security features help keep the system safe and prevent tampering.

Multi-language and multi-user interfaces

Many systems have operators who speak different languages. Modern HMIs can support multiple languages. This makes it easier for everyone to use the system. Also, multiple operators can use the HMI at the same time.

Let's explore the real-world benefits of HMIs in more detail!

Benefits of Using HMIs in Industrial Automation

How can HMIs make a real difference in your industrial operations? Are they just a nice-to-have, or are they essential?

HMIs offer increased efficiency, enhanced operator productivity and safety, data-driven decision-making, faster troubleshooting, and easy scalability. These benefits lead to significant improvements in performance and ROI.

Increased efficiency and uptime

HMIs help operators run their systems more efficiently. By seeing real-time data, they can make changes to optimize performance. HMIs also help reduce downtime. Operators can spot problems early and fix them before they cause big issues.

Enhanced operator productivity and safety

HMIs make operators more productive. I've seen this firsthand. They have all the information they need at their fingertips. They can control the system from a single location. HMIs also improve safety. By alerting operators to problems, they can prevent accidents.

Better decision-making through visualized data

When operators understand the data, their decisions get much better. HMIs show data in a way that's easy to understand. Operators can use this data to make informed decisions about how to run the system. This leads to better performance and fewer mistakes.

Faster troubleshooting and diagnostics

HMIs make it easier to find and fix problems. When something goes wrong, the HMI will show an alarm. Operators can use the HMI to see what's happening and identify the cause of the problem. This makes troubleshooting faster and easier.

Scalability for future tech upgrades

HMIs are designed to grow as your operations grow. They can be easily upgraded to support new technologies. This means that you can keep your HMIs up-to-date without having to replace them entirely.

Before we continue, think about how these benefits would apply to your situation. Next, let's address industries that use HMI!

Industries That Rely on HMI Technology

Is HMI just for big factories, or are they used in a variety of industries? Are they just a piece of tech, or are they also a sign of future development?

HMIs are used in many industries, including manufacturing, oil & gas, food processing, water treatment, smart buildings, and more. They provide the necessary control and monitoring to optimize operations in different settings. HMIs are constantly needed in places with a high degree of automation and can bring people and facilities together.

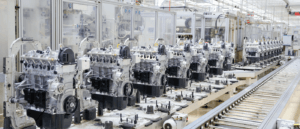

Manufacturing and assembly lines

In manufacturing, HMIs are used to control and monitor machines and processes. They help operators keep the assembly line running smoothly and efficiently. They show data on production rates, machine status, and error messages. Assembly Line workers use HMIs to identify the source of issues quickly.

Oil & gas and energy production

In the oil and gas industry, HMIs are used to monitor pipelines, refineries, and drilling platforms. They show data on pressure, temperature, and flow rates. HMIs help operators keep the system running safely and efficiently.

Food and beverage processing

In food processing, HMIs are used to control and monitor food production lines. They show data on temperature, humidity, and production rates. HMIs help ensure that food is processed safely and efficiently.

Water treatment and utilities

In water treatment plants, HMIs are used to monitor water quality and control the treatment process. They show data on pH levels, chlorine levels, and water flow rates. HMIs help ensure that water is safe to drink.

Smart buildings and infrastructure

In smart buildings, HMIs are used to control lighting, HVAC systems, and security systems. They show data on energy usage, temperature, and occupancy. HMIs help operators manage building resources more efficiently.

Now that you know which industries rely on HMI technology, let's look at some real-world case studies!

Real-World Examples and Use Cases

What are some real-world examples of HMIs in action? What kind of results do companies see when they implement HMI solutions?

In an automotive plant, HMI dashboards8 improved throughput. A water treatment facility reduced downtime through real-time alerts9. A packaging line integrated HMI with vision inspection systems. These case studies demonstrate the tangible benefits of HMIs in improving efficiency and ROI.

Case 1: Automotive plant improving throughput with HMI dashboards

An automotive plant used HMI dashboards to track production rates and identify bottlenecks. The dashboards showed real-time data on machine status, production volume, and error messages. By using this data, the plant was able to improve throughput by 15%.

Case 2: Water treatment facility reducing downtime through real-time alerts

A water treatment facility used an HMI to monitor water quality and control the water treatment process. When something went wrong, the HMI would send an alert to the operators. By responding to these alerts quickly, the facility was able to reduce downtime by 20%.

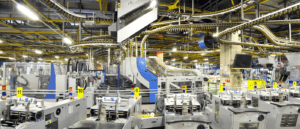

Case 3: Packaging line integrating HMI with vision inspection systems

A packaging line integrated an HMI with a vision inspection system. The HMI showed data on the quality of the packaging. The vision inspection system would automatically reject any packages that didn't meet quality standards. By using this system, the packaging line was able to improve quality and reduce waste.

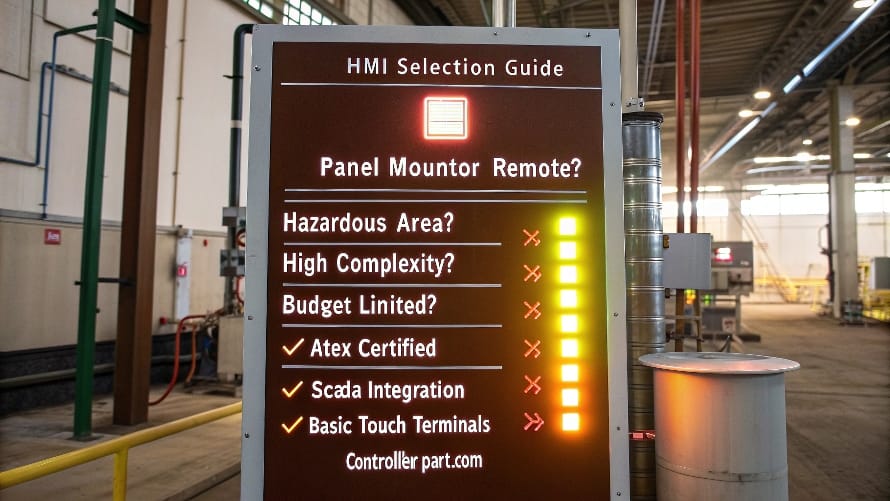

Choosing the Right HMI for Your Application

Are you trying to pick the right HMI for your needs? What are the key things to consider?

Consider factors like the environment, complexity, and budget. Decide between panel-mounted and remote HMIs. Compare vendors and ensure compatibility with your existing PLC systems. Doing this will help you choose an HMI that meets your needs and is within your budget.

Factors to consider: environment, complexity, budget

When picking an HMI, think about the environment where it will be used. HMIs used in harsh environments need to be rugged. Also, think about the complexity of your application. Simple applications don't need very sophisticated HMIs. Finally, consider your budget. HMIs can range in price from a few hundred dollars to thousands of dollars.

Panel-mounted vs. remote HMIs

Panel-mounted HMIs are mounted on a control panel. They're good for applications where the operator needs to be close to the machines. Remote HMIs can be accessed from anywhere. They're good for applications where the operator needs to monitor the system from a remote location.

Installation Comparison: Real-World Performance

| Feature | Panel-Mounted HMI | Remote HMI | What This Means For You |

|---|---|---|---|

| Physical Security | ★★★★★ (Lockable enclosures) | ★★☆☆☆ (Portable devices) | Prevents unauthorized access in high-traffic areas |

| Environmental Resistance | ★★★★★ (IP65+ ratings) | ★★☆☆☆ (Limited protection) | Withstands harsh conditions like dust, moisture, and chemicals |

| Operator Ergonomics | ★★☆☆☆ (Fixed position) | ★★★★★ (Adjustable placement) | Reduces fatigue in extended operations |

| Installation Cost | ★★☆☆☆ ($500-$2000) | ★★★★★ ($200-$800) | Lower upfront cost for remote units |

| Maintenance | ★★★★★ (10+ year lifespan) | ★★☆☆☆ (3-5 year replacement) | Higher long-term value for panel units |

| Upgrade Flexibility | ★☆☆☆☆ (Difficult to modify) | ★★★★☆ (Easy to swap) | Faster technology updates with remote |

Critical decision factors:

- Washdown areas → Always panel-mounted (IP69K)

- Mobile operators → Remote tablets with rugged cases

- High-vibration zones → Panel-mounted with shock mounts

- Temporary lines → Remote for quick reconfiguration

Pro Tip: We install 80% panel-mounted in heavy industry - their reliability justifies the cost. For labs or pilot lines? Remote wins for flexibility. Never mix types in the same control scheme - it creates maintenance nightmares.

Vendor comparison tips

When comparing vendors, look at the features they offer. Also, look at their reputation and customer support. Get references from other customers.

How to ensure compatibility with existing PLC systems

Make sure the HMI is compatible with your existing PLC systems. Check the HMI's specifications to see which PLCs it supports. You may need to buy special drivers or software to make the HMI work with your PLC.

Conclusion

HMIs are more than just plain old screens. They are a command center for any modern industry. Selecting the right HMI can improve your productivity, safety, and ROI.

Natalie's Insights: HMIs Are the Freakin’ Core of Automation—Move Fast!

HMIs are the pulse of industry, not just shiny screens. They cut through data chaos, connect with PLCs and SCADA, and let you run factories, rigs, or plants like a boss. Ditch old buttons for IoT-ready, multi-language touchscreens that work anywhere. Pick the right HMI—rugged or remote—and you’ll save time, cut costs, and crush it. This is the future. Get on it now.

The Unmatched Supply Chain Reality

China's PLC advantages come from systemic factors, not just lower labor costs:

- Component clustering: 90% of parts sourced within 100km

- Demand density: Factories consume 38% of global PLCs

- Policy support: VAT rebates for automation exports.

My Turning Point:

A client needed customized PROFINET integration. The European quote: €15,000, 3 months. Our Chinese partner delivered for €2,800 in 18 days - because they had the chip designer on-site.

Key Structural Differences Western Buyers Often Miss

| Factor | Chinese Context | European/North American Context |

|---|---|---|

| R&D Speed | Average 5.8 prototype iterations/year | 1-2 iterations/year |

| Production Flexibility | 73% factories can change specs mid-production | Requires new work orders |

| After-Sales Model | 68% include free lifetime support | Typically 1-3 years paid support |

The Realities You Should Know

After auditing 27 Chinese factories, here's what surprised me:

- 80% use German/Japanese production equipment

- Average R&D investment is 8.2% of revenue (vs 5.4% globally)

- 76% now offer lifetime technical support - unheard of in the West

The decision isn't about "good vs bad" PLCs. It's understanding how China's manufacturing ecosystem delivers different value propositions. [Message me] for our unvarnished supplier assessment templates.

Explore this link to gain a deeper understanding of HMIs and their significance in industrial automation. ↩

Learn about SCADA systems to understand their role in industrial control and how they complement HMIs for better management. ↩

Discover the latest advancements in industrial automation to stay ahead in the field and improve operational efficiency. ↩

Discover how web-based HMIs can provide flexibility and accessibility for monitoring systems from anywhere. ↩

Exploring advanced HMI platforms can help you choose the right tools for complex industrial operations. ↩

Understanding real-time monitoring can enhance your operational efficiency and decision-making in industrial settings. ↩

Explore how real-time monitoring enhances operational efficiency and decision-making in industrial settings. ↩

Explore how HMI dashboards can enhance production efficiency and decision-making in manufacturing environments. ↩

Learn how real-time alerts can significantly reduce downtime and enhance operational efficiency in water treatment processes. ↩